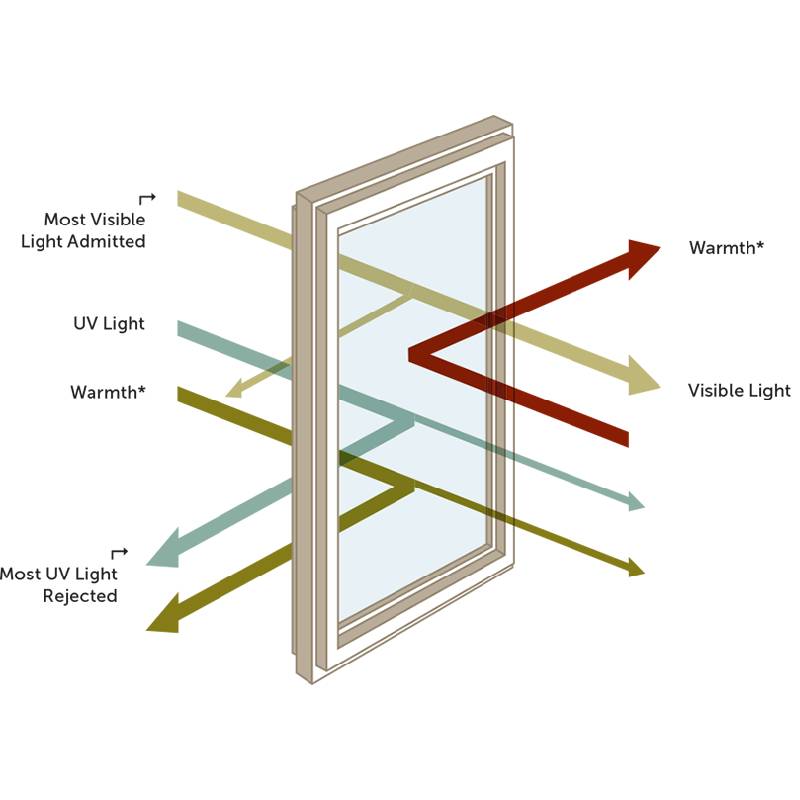

In the contemporary architectural and automotive landscapes, energy efficiency stands as a paramount design and functional criterion, driving innovation across various material sciences. Among these advancements, types of low e glass have emerged as a pivotal solution for optimizing thermal performance in glazing systems. This specialized glass is engineered with microscopic, transparent metallic coatings that are significantly thinner than a human hair, designed to selectively reflect long-wave infrared (IR) radiation, which is the primary component of heat, while allowing short-wave visible light to pass through. The fundamental principle behind low-emissivity (Low-E) glass revolves around its ability to reduce heat transfer through windows, thereby enhancing indoor comfort and substantially lowering heating and cooling costs. This technology is becoming increasingly critical in response to global climate initiatives and rising energy prices, necessitating materials that can effectively manage solar heat gain in warm climates and minimize heat loss in colder regions. The continuous evolution of coating technologies, from initial single-layer designs to advanced multi-layer systems, has broadened the applicability and performance spectrum of low-E glass, making it an indispensable component in modern high-performance buildings and vehicles that prioritize sustainability and occupant well-being.

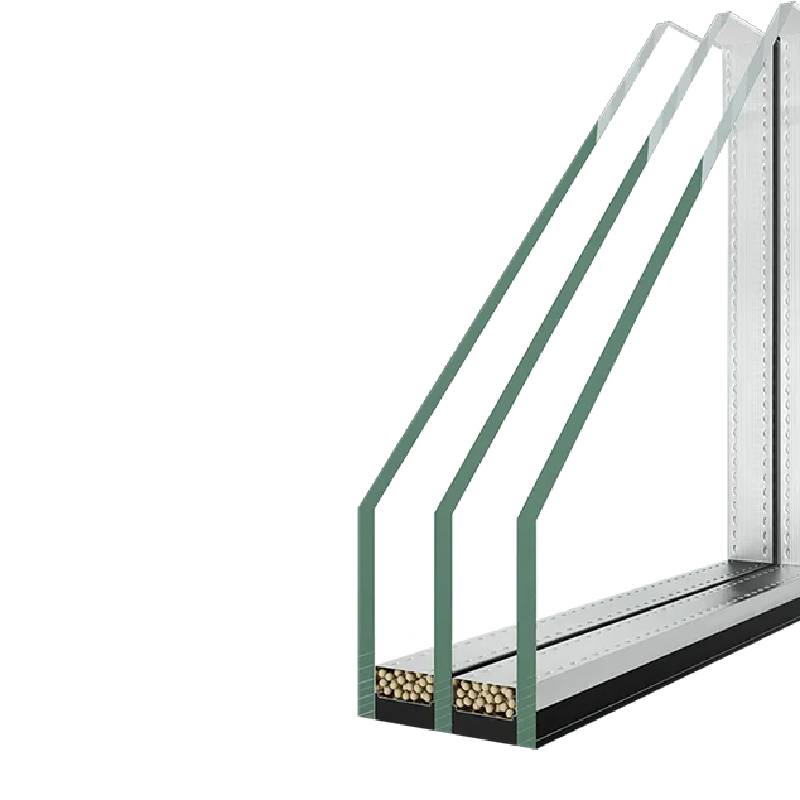

The demand for sophisticated glazing solutions is escalating, driven by stringent building codes, increased awareness of environmental footprints, and the desire for enhanced aesthetic appeal. Different types of low e glass cater to a diverse array of applications, each optimized for specific climatic conditions and performance objectives. For instance, in colder climates, coatings are designed to minimize heat loss from inside, reflecting radiant heat back into the building, while in warmer climates, the focus shifts to reducing solar heat gain from the outside, preventing interiors from overheating. This adaptability makes low-E glass a versatile material, capable of addressing complex thermal challenges in both residential and commercial sectors. Furthermore, the integration of low-E coatings into insulated glass units (IGUs) — commonly seen as low e glass double glazing — amplifies their thermal performance by incorporating inert gases like argon or krypton between the glass panes, which further reduces conductive and convective heat transfer. The meticulous engineering of these coatings and glass configurations ensures that users benefit from significant energy savings, improved comfort, reduced UV radiation exposure for interiors, and a higher quality of natural light, all contributing to a more sustainable and economically viable built environment.

The production of low-E glass involves sophisticated manufacturing processes, primarily categorized into two distinct methods: pyrolytic (hard coat) and sputtered (soft coat). Each method imparts unique characteristics to the final product, influencing its performance parameters, durability, and aesthetic properties. The pyrolytic process involves applying a metallic oxide coating to the glass ribbon while it is still hot during the float glass manufacturing process. This creates a durable, fused layer that is highly resistant to scratches and abrasions, making it suitable for applications where the coating might be exposed, such as single-pane windows or storm windows. The chemical vapor deposition (CVD) technique used in pyrolytic coating ensures a strong molecular bond with the glass substrate, leading to excellent longevity and ease of handling during fabrication. While hard coat low-E offers good thermal performance, its spectral selectivity, which refers to its ability to block heat while allowing visible light, is generally less precise than soft coat alternatives. This method is often employed for general-purpose applications where durability is prioritized over maximal thermal performance. The consistency and reliability of this process are key factors in its widespread adoption for specific types of low e glass requirements.

Conversely, the sputtered process, also known as soft coat low-E, involves applying multiple layers of silver or other metallic compounds in a vacuum chamber at room temperature using magnetron sputtering technology. This method allows for greater precision in controlling the coating's properties, enabling the creation of highly spectrally selective coatings that can significantly reduce solar heat gain while maintaining high visible light transmittance. Soft coat low-E is typically incorporated into insulated glass units (IGUs) because the delicate coating requires protection from environmental exposure, usually placed on surfaces 2 or 3 within the IGU. The layers can be as few as one (single silver) or as many as three (triple silver), with each additional silver layer enhancing thermal performance by further reducing the emissivity. The versatility of sputtering allows manufacturers to fine-tune the coating for specific U-values, Solar Heat Gain Coefficients (SHGC), and Visible Light Transmittance (VLT) values, making these low e glass panels ideal for high-performance architectural projects. Quality control during both processes adheres to rigorous standards such as ISO 9001 for manufacturing and ASTM standards for performance (e.g., ASTM E2190 for IGUs), ensuring that the finished product meets stringent global building and energy efficiency regulations. The lifespan of properly installed low-E glass, especially within an IGU, can easily exceed 20-30 years, demonstrating its long-term value in various demanding applications.

Understanding the technical parameters is crucial for selecting the appropriate low-E glass for sale for any given project. Key performance indicators include the U-value, Solar Heat Gain Coefficient (SHGC), and Visible Light Transmittance (VLT). The U-value measures the rate of heat transfer through a window; a lower U-value indicates better insulation and less heat loss or gain. SHGC quantifies the fraction of solar radiation admitted through a window, directly transmitted, and absorbed and subsequently released inward; a lower SHGC is desirable in hot climates to reduce cooling loads. VLT represents the percentage of visible light that passes through the glass; a higher VLT ensures ample natural light. Emissivity, a fundamental property of the coating, defines its ability to emit radiant energy; lower emissivity values correlate directly with superior thermal performance. For example, a typical clear insulated glass unit might have a U-value of around 0.47, an SHGC of 0.62, and a VLT of 0.81. Incorporating a single-silver soft coat low-E can improve these to a U-value of 0.29, an SHGC of 0.38, and a VLT of 0.70. For applications requiring maximum thermal control, triple-silver soft coat low-E can achieve U-values as low as 0.24, SHGC values around 0.23, and VLT values of 0.60. These significant improvements highlight why understanding the different types of low e glass and their precise specifications is paramount for energy-efficient building design and operation.

The choice between different types of low e glass also depends on geographical location and desired visual aesthetics. In very cold climates, a high-gain low-E coating that maximizes solar heat gain while minimizing heat loss is often preferred. Conversely, in hot, sunny climates, a low-gain or spectrally selective coating that blocks solar heat but allows ample visible light is more suitable. The orientation of the window within a building also plays a role; south-facing windows might benefit more from a low-SHGC coating, while north-facing windows might prioritize minimal U-value. Leading manufacturers often provide comprehensive data sheets compliant with NFRC (National Fenestration Rating Council) standards, allowing architects and builders to precisely model the energy performance of their projects. Our commitment to providing detailed technical specifications and offering expert consultation ensures that clients can confidently select the ideal low e glass solution that meets their specific performance requirements and regulatory compliance needs, ensuring long-term energy savings and occupant comfort.

The versatility of low e glass extends across a multitude of industries, driven by its exceptional energy-saving capabilities and comfort-enhancing properties. In the commercial building sector, particularly for offices, retail spaces, and hotels, low-E glass panels are integral to creating sustainable and cost-efficient envelopes. They significantly reduce the demand for HVAC systems, leading to lower operational expenditures and a reduced carbon footprint. For residential applications, low e glass double glazing enhances comfort by mitigating cold spots near windows in winter and reducing heat ingress in summer, ensuring a stable indoor temperature year-round. Beyond traditional building envelopes, low-E glass finds critical applications in specialized environments. For example, in museums and art galleries, its ability to filter harmful UV radiation protects valuable artifacts and artworks from fading and deterioration, without compromising visible light transmission. In greenhouse structures, specific types of low e glass can be tailored to control the spectral distribution of light, optimizing plant growth while maintaining thermal stability. Furthermore, the automotive industry increasingly adopts low-E glass for vehicle windshields and side windows, improving fuel efficiency by reducing the strain on air conditioning systems and enhancing passenger comfort by minimizing solar heat build-up.

The technical advantages of integrating low-E glass are multifaceted. Firstly, significant energy savings are realized, with studies showing potential reductions of up to 30-40% in annual heating and cooling costs compared to standard clear glass. Secondly, improved occupant comfort is a direct benefit, as the glass helps to maintain more consistent indoor temperatures, eliminating uncomfortable drafts or excessive warmth near windows. Thirdly, the protection of interior furnishings and assets from harmful UV radiation ensures longer lifespan for carpets, furniture, and artworks. Fourthly, its acoustic insulation properties, especially when used in low e glass double glazing configurations with varying glass thicknesses or laminated layers, contribute to quieter indoor environments, a crucial factor in urban settings or near high-traffic areas. Lastly, the flexibility in design, allowing for large expanses of glass without compromising energy performance, empowers architects to create visually striking and light-filled spaces. Our diverse range of low e glass for sale can be customized to specific project requirements, ensuring optimal performance for varied applications, from high-rise commercial towers to specialized refrigeration display units, demonstrating its indispensable role in modern, energy-efficient design.

At TPTopGlass, our expertise extends beyond standard product offerings to encompass comprehensive custom solutions for all types of low e glass needs. We understand that each project presents unique challenges and opportunities, requiring tailored specifications to achieve optimal performance and aesthetic integration. Our team of technical specialists collaborates closely with architects, developers, and contractors from the initial design phase through to installation, providing in-depth consultation on everything from U-value and SHGC optimization for specific climatic zones to intricate structural considerations for large-format low e glass panels. For instance, in a recent high-rise commercial project in a region with significant solar exposure, we engineered a bespoke triple-silver soft coat low-E glass solution, integrated into a custom-sized low e glass double glazing unit with an enhanced argon gas fill. This not only dramatically reduced the building's cooling load by over 35% but also maintained a VLT that maximized natural daylighting, garnering positive feedback from occupants regarding thermal comfort and visual clarity. This commitment to precise engineering and client satisfaction underscores our reputation as an authoritative partner in the architectural glass industry.

Our unwavering commitment to quality and customer satisfaction is reinforced by robust certifications and industry compliance. All our low e glass products adhere to international standards such as ISO 9001 for quality management and ASTM E2190 for Insulating Glass Units. We proudly hold certifications from recognized bodies like the National Fenestration Rating Council (NFRC) and the Insulating Glass Certification Council (IGCC), ensuring that our low e glass for sale meets the highest performance and safety benchmarks. With over 20 years of experience in the glass manufacturing sector, our longevity and extensive portfolio of successful projects stand as a testament to our authoritativeness. We have cultivated strong relationships with leading architectural firms and construction companies globally, providing cutting-edge low e glass solutions that consistently exceed expectations. Our service capabilities include comprehensive pre-sales consultation, detailed technical drawings, efficient production with a typical delivery cycle of 3-4 weeks for standard orders and 6-8 weeks for highly customized solutions, and dedicated after-sales support with a standard 10-year warranty on insulating glass units against seal failure. This holistic approach ensures not only a superior product but also a seamless, trustworthy experience for our valued clients.

Hard coat (pyrolytic) low e glass is manufactured by applying the coating during the float glass process, fusing it to the glass. This makes it highly durable and suitable for exposed surfaces, but its thermal performance is generally moderate. Soft coat (sputtered) is applied in a vacuum chamber after the glass is formed, resulting in a more delicate but significantly higher-performing coating with superior U-values and SHGCs. It must be protected within an insulated glass unit (IGU), such as in low e glass double glazing. The choice between these different types of low e glass depends on the specific application's durability requirements, desired energy performance, and aesthetic considerations, as soft coat can also offer a wider range of visual appearances due to multi-layer options.

Low-E glass reduces energy consumption by minimizing heat transfer through windows. In colder climates, it reflects indoor heat back into the building, preventing loss. In warmer climates, it reflects solar radiation away, reducing heat gain and lessening the burden on air conditioning systems. This selective reflection of infrared energy, while allowing visible light through, creates a more stable indoor environment, significantly cutting down on heating and cooling costs. The specific coating types of low e glass dictate the precise balance of solar gain and heat retention, allowing for tailored energy performance based on regional climate and building design. The U-value and SHGC parameters are critical indicators of this energy performance.

Absolutely. Customization is a core aspect of our low e glass for sale offerings. We can tailor the coating specifications (e.g., single, double, or triple silver layers), glass thickness, size, shape, tint, and integration into various insulated glass unit configurations (including argon or krypton gas fills) to meet unique project requirements. Whether you need specific U-values, SHGCs, VLTs, or aesthetic finishes, our technical team works closely with clients to design and manufacture low e glass panels that perfectly align with architectural visions and performance targets. This bespoke approach ensures optimal energy efficiency, comfort, and visual appeal for any commercial or residential application, ensuring a precise fit for complex fenestration systems.

When properly installed and maintained within an insulated glass unit, low e glass can have an impressive lifespan, typically exceeding 20-30 years. The durability of the coating, especially hard coat variants, ensures long-term performance. For soft coat low-E, which is protected within the IGU, the primary factor for longevity is the integrity of the unit's seal. We provide a standard 10-year warranty against seal failure in our insulated glass units, demonstrating our confidence in the quality and durability of our products. This warranty offers peace of mind and assures clients of the long-term investment value, minimizing potential future maintenance or replacement costs and cementing trust in our manufacturing processes for all our types of low e glass.