Tin float glass, a cornerstone in modern architectural design, represents the pinnacle of glass manufacturing innovation. As an indispensable material in the construction and automotive industries, understanding its strengths and applications can significantly enhance design efficiency and aesthetic appeal.

Derived from the float process invented by Sir Alastair Pilkington in the 1950s, tin float glass undergoes a unique production method. Molten glass is poured onto a bed of molten tin, where it spreads out and flattens. The result is a remarkably smooth, distortion-free surface—ideal for both functional and decorative applications. This method not only guarantees uniform thickness but also ensures a flawless finish, making it the preferred choice for high-quality installations.

The expertise behind manufacturing tin float glass ensures consistency in quality and performance. State-of-the-art technological advancements in the production lines have minimized impurities and defects. This precision is vital for applications requiring optical clarity, such as in high-definition displays and sophisticated architecture. Moreover, enhanced coating technologies applied to this glass type offer superior thermal and acoustic insulation, contributing to energy-efficient buildings.

In terms of trustworthiness and reliability, tin float glass surpasses its counterparts. Extensive testing and quality assurance processes underpin its use in safety-critical applications. For instance, in automotive industries, its robust nature and clarity are utilized for windshields and panoramic roofs, providing safety and a seamless view. Architects leverage these trust factors to implement creative solutions that transform urban skylines.

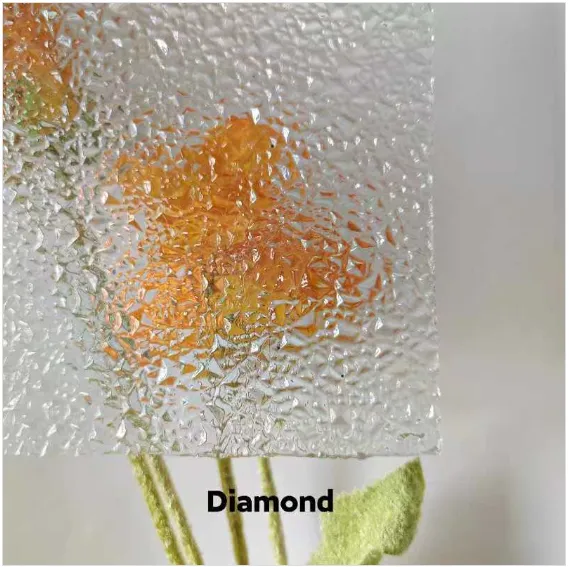

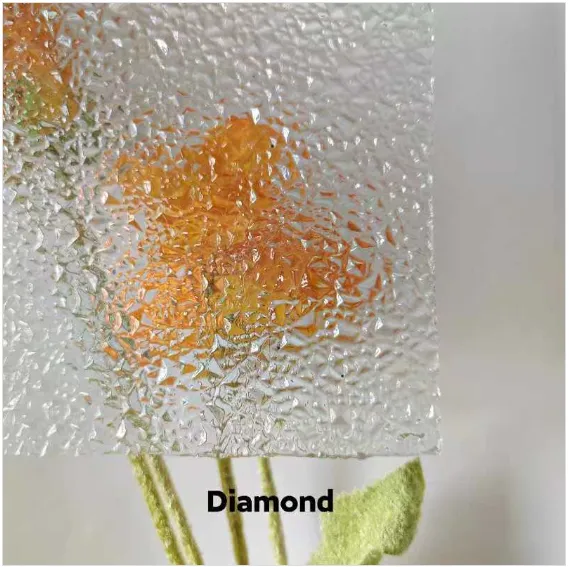

tin float glass

Authoritative industry bodies often recommend tin float glass, cementing its status as a leading material. Certification from international standards organizations ensures that the material meets stringent safety and performance criteria. Compliance with these standards is crucial for projects aiming for sustainability and environmental certifications, such as LEED or BREEAM.

Experienced professionals in the industry attest to the versatility of tin float glass in achieving various design intentions. From ultra-modern skyscrapers to classic interior spaces, its adaptability is evident. Designers appreciate its ability to merge with innovative technologies such as smart glass films, which adjust transparency based on lighting conditions, optimizing indoor environments.

Real-world applications highlight the profound impact of tin float glass on contemporary design. From landmark structures like the Louvre Abu Dhabi to sprawling corporate campuses, its use exemplifies a blend of aesthetics and practicality. These structures stand as a testament to the material's potential in revolutionizing architectural philosophies.

In conclusion, for practitioners seeking a material that embodies experience, expertise, authoritativeness, and trustworthiness, tin float glass presents an unrivaled option. Its continued evolution in response to modern challenges reaffirms its position at the forefront of design innovation. As industries advance towards smarter and more sustainable solutions, tin float glass remains a pivotal resource, inspiring the next generation of architectural masterpieces.