The market for high-quality reflective surfaces continues to expand, driven by advancements in optics, renewable energy, and architectural design. Among these, the silver mirror for sale stands out as a premier choice due to its exceptional reflectivity and durability. This material, often featuring a solid silver mirror or surface silvered mirror construction, is critical in applications demanding superior optical performance, ranging from precision scientific instruments to large-scale solar power installations. Understanding the intrinsic value and technical specifications of these products is paramount for B2B procurement professionals and engineers seeking optimal solutions.

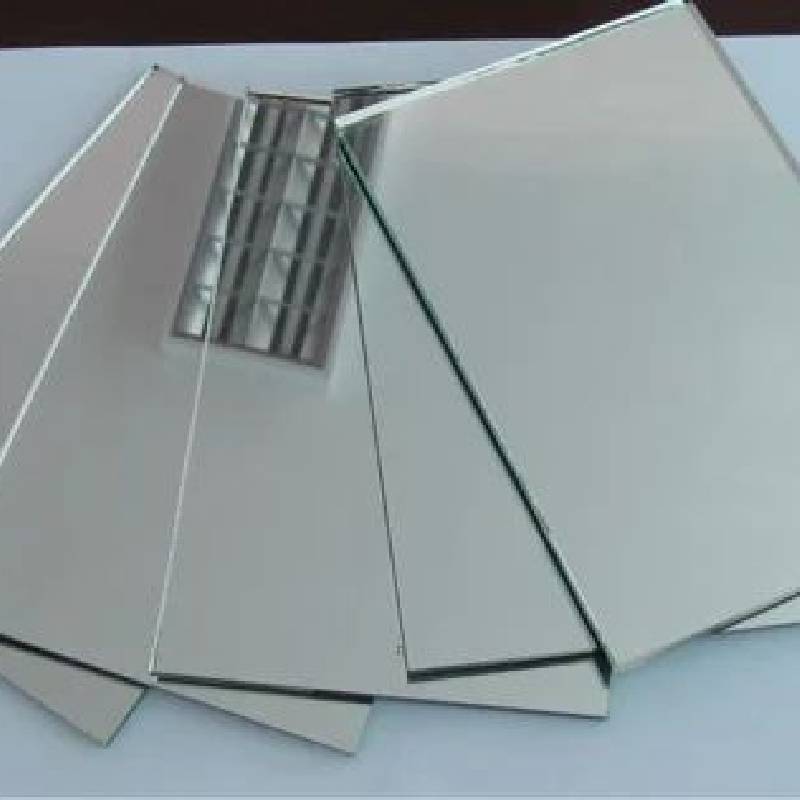

Modern manufacturing techniques have significantly enhanced the performance and longevity of silver mirrors. The trend is moving towards more resilient coatings and precise deposition processes that minimize defects and maximize light return. For instance, enhanced silver mirrors are now commonly equipped with advanced protective layers that offer superior resistance to oxidation and abrasion, expanding their operational lifespan even in challenging environmental conditions. The demand for specialized variants like square silver mirrors for specific optical paths or sterling silver mirrors for decorative and high-end aesthetic applications further underscores the diverse requirements within the industry.

As industries push for greater efficiency and reliability, the selection of reflective components becomes a critical determinant of overall system performance. This guide delves into the detailed aspects of silver mirror technology, from its intricate manufacturing processes to its varied applications and the quality assurance protocols that ensure consistent, high-grade products. We will explore key technical parameters, illustrate real-world applications, and provide insights into selecting the right silver mirror solution for your specific project needs, focusing on aspects that contribute to long-term value and operational excellence.

The production of a high-quality silver mirror is a sophisticated multi-stage process, demanding precision and adherence to rigorous standards. It typically begins with carefully selected, high-grade float glass, ensuring a flat, distortion-free substrate. The glass undergoes a thorough cleaning process, including demineralized water rinses and chemical washes, to remove any surface contaminants that could compromise adhesion or optical quality. This meticulous preparation is crucial for achieving the desired reflective properties and preventing premature degradation of the mirror surface.

Following cleaning, the core reflective layer is applied. Traditionally, this involves the deposition of a silver nitrate solution onto the glass surface, often in a carefully controlled environment to ensure uniform coverage. This chemical silvering process creates a thin, highly reflective metallic silver layer. In advanced manufacturing, physical vapor deposition (PVD) or sputtering techniques may also be employed for even greater control over film thickness and purity, resulting in a superior surface silvered mirror. A critical aspect of this stage is achieving optimal adhesion between the silver and the glass, which is often facilitated by a tin chloride sensitizing layer.

Once the silver layer is applied, it is protected by multiple layers of paint or polymer coatings. These protective layers, typically one or two coats, shield the delicate silver from oxidation, moisture, and mechanical damage, significantly extending the mirror's lifespan. The first coat is often a corrosion-resistant barrier, while the second provides additional protection and structural integrity. For certain applications, an additional copper layer might be applied between the silver and the protective paint to enhance durability, though modern copper-free silver mirrors are increasingly popular due to environmental considerations and their robust performance. All stages of this process are subject to strict quality control, adhering to international standards such as ISO 9001 for quality management and relevant ASTM or EN standards for material performance. Typical lifespan for a well-manufactured silver mirror can exceed 15-20 years in indoor applications, demonstrating exceptional durability.

These meticulously produced silver mirrors find extensive use across various industries, including architectural glazing for light management, furniture manufacturing for aesthetic appeal, and critical components in solar thermal collectors for energy applications. In industries such as petrochemical, metallurgy, and water supply/drainage, while direct mirror application might be niche, the underlying material science and coating technologies contribute to other optical or protective elements. The high reflectivity of a quality silver mirror ensures maximum light and energy capture, offering advantages such as energy efficiency in lighting systems and superior image clarity in display technologies.

When evaluating a silver mirror for sale, several key technical parameters are critical for ensuring it meets specific application requirements. Reflectivity is paramount, with standard silver mirrors typically achieving a visible light reflectivity of 88-92%. Enhanced versions can push this to 95% or higher, crucial for high-efficiency optical systems. Understanding the spectral reflectivity curve, which illustrates reflectivity across different wavelengths, is also vital for applications like solar energy concentration or specialized lighting.

Durability is another significant factor, quantified by resistance to corrosion, abrasion, and moisture. Manufacturers often provide data on salt spray tests (e.g., ASTM B117) and humidity tests, which simulate harsh environmental conditions. The thickness of the glass substrate, ranging from 2mm to 12mm, directly impacts the mirror's rigidity and suitability for various structural applications. For instance, thinner mirrors are preferred for lightweight designs, while thicker ones offer greater stability for large installations or demanding environments.

| Parameter | Standard Range | Typical High-Performance | Relevant Standard / Test |

|---|---|---|---|

| Visible Light Reflectivity | 88% - 92% | >95% | ASTM E1347, ISO 9050 |

| Glass Thickness | 2mm - 12mm | 3mm - 6mm (most common) | EN 572-2, ANSI Z97.1 |

| Protective Layers | Single or Double Coat | Double, copper-free paint | Proprietary / Industry Best Practices |

| Corrosion Resistance | >240 hrs (Salt Spray) | >500 hrs (Salt Spray) | ASTM B117 |

| Humidity Resistance | >120 hrs (Constant Humidity) | >240 hrs (Constant Humidity) | ASTM D2247 |

| Edge Work | Cut, Ground, Polished | Bevelled, Seamed, CNC processed | Custom per design |

The choice between a standard silver mirror and an enhanced version, or specific types like a solid silver mirror or surface silvered mirror, often comes down to a cost-benefit analysis concerning the application's demands for optical purity, longevity, and environmental resilience. Factors such as the presence of lead-free paints or the use of recycled glass substrates are also becoming increasingly important, reflecting a growing industry commitment to sustainability and compliance with environmental regulations like RoHS.

The versatility of the silver mirror makes it an indispensable component across a multitude of industries, driven by its superior reflective qualities. In architectural design, large sheets of silver mirror are used to enhance spatial perception, reflect light into interior spaces, and create visually expansive environments in commercial buildings and residential developments. These applications often benefit from custom-cut square silver mirrors or larger panels, which can be integrated into wall cladding, decorative features, and even light shelf systems for passive daylighting, contributing to significant energy savings by reducing reliance on artificial lighting.

Beyond aesthetics, the technical advantages of a high-performance silver mirror for sale are particularly evident in specialized fields. In the solar energy sector, precisely manufactured silver mirrors are crucial for concentrating solar radiation onto receivers in concentrated solar power (CSP) plants, where maximizing reflectivity directly translates to higher energy yields and system efficiency. Similarly, in optical instruments, from telescopes to high-magnification microscopes, the low absorption and minimal chromatic aberration offered by a quality silver mirror ensure clearer, more accurate imaging.

Our clients have consistently reported enhanced performance and longevity in their products and installations after integrating our specialized silver mirrors. For instance, a leading furniture manufacturer noted a 30% reduction in customer complaints related to mirror degradation after switching to our advanced corrosion-resistant models. Another client in the scientific instrumentation sector praised the optical clarity of our custom sterling silver mirrors, which improved the precision of their laboratory equipment. These case studies underscore the tangible benefits of investing in a premium surface silvered mirror: superior durability translating into reduced maintenance costs and an extended product lifecycle, alongside exceptional visual fidelity.

Furthermore, the anti-corrosion properties inherent in modern silver mirrors significantly benefit applications in high-humidity or chemically aggressive environments, typical of certain industrial processes or bathroom installations. The robust protective layers ensure that the reflective surface remains pristine over extended periods, minimizing the need for replacement and contributing to a more sustainable operational model. This blend of high performance and long-term reliability makes silver mirrors a preferred choice for B2B applications where both initial quality and sustained performance are critical.

Recognizing that every B2B project presents unique challenges, manufacturers specializing in silver mirror for sale often provide extensive customization options. This includes varying thicknesses (from 2mm to 12mm), custom shapes (e.g., precise square silver mirrors, circular, or irregular cuts), and specialized edge work (e.g., polished, beveled, seamed). The ability to specify precise dimensions and finishes ensures seamless integration into complex designs, from custom furniture to bespoke architectural elements or industrial equipment. Moreover, tailored protective coatings can be applied to enhance resistance against specific environmental factors, such as high humidity, chemical exposure, or extreme temperatures, extending the mirror's life in demanding conditions.

Authoritativeness in the silver mirror industry is built on a foundation of rigorous testing and certifications. Reputable manufacturers adhere to international quality management systems such as ISO 9001, ensuring consistent product quality from raw material sourcing to final delivery. Compliance with product-specific standards like EN 1036 (Mirrors for interior use - Silvered float glass for indoor use) or ASTM C1503 (Standard Specification for Silvered Flat Glass Mirror) further demonstrates a commitment to excellence. Our long-standing relationships with industry-leading glass suppliers, coupled with decades of experience in mirror manufacturing, reinforce our position as an authoritative source for high-quality silver mirror products.

Furthermore, many suppliers offer comprehensive quality assurance programs, which include in-house testing facilities capable of performing optical performance measurements, adhesion tests, and environmental resistance simulations (e.g., salt spray tests, humidity chamber tests). Such commitment to quality is often backed by transparent test data and performance reports, providing clients with verifiable proof of product reliability. This rigorous approach ensures that every solid silver mirror or surface silvered mirror delivered meets the stringent performance requirements expected by industrial and commercial clients, fostering trust and long-term partnerships.

Our dedicated technical support team is always available to assist with product selection, technical specifications, and custom design inquiries, ensuring that every client receives a solution perfectly aligned with their project's unique needs. This end-to-end support, combined with clear warranties and reliable delivery schedules, solidifies our trustworthiness in the B2B market for silver mirrors.

A silver mirror typically offers higher reflectivity (up to 95% in visible light) compared to an aluminum mirror (around 85-90%). This superior reflectivity is due to silver's inherently higher efficiency in reflecting visible light. While aluminum mirrors are often more cost-effective and have good UV resistance, silver mirrors provide a brighter, clearer image with less color distortion, making them preferred for applications where optical clarity and high light return are paramount, such as precision optics, decorative purposes, or energy-efficient lighting designs. The choice depends heavily on the specific application's budget and performance requirements, but for premium optical performance, a silver mirror for sale remains the top choice.

Lead times for bulk orders of custom silver mirrors can vary depending on the complexity of the customization, quantity, and current production schedules. Generally, for standard sizes and thicknesses, the lead time might range from 15 to 25 business days from order confirmation. For highly customized dimensions, intricate shapes like unique square silver mirrors, specialized coatings, or very large volumes, this can extend to 30-45 business days. We recommend contacting our sales team directly with your specific requirements for an accurate lead time estimate, as we prioritize efficient production and reliable delivery for all our clients.

We stand behind the quality of our silver mirror products with a comprehensive warranty against manufacturing defects and premature deterioration of the reflective layer under normal use conditions. Our standard warranty typically covers a period of 5 to 10 years, depending on the product type and specific application. This commitment reflects our confidence in the durability and longevity of our solid silver mirror and sterling silver mirrors, which are manufactured using advanced techniques and high-quality materials. Detailed warranty terms and conditions are provided with each quotation and order. Our customer support team is always available to address any concerns or claims promptly and efficiently.

Yes, our silver mirror manufacturing processes prioritize environmental responsibility. We offer copper-free and lead-free silver mirror options, which eliminate harmful heavy metals and simplify disposal and recycling. Our products are designed to meet or exceed international environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). We continuously invest in cleaner production technologies to minimize our environmental footprint, ensuring that our surface silvered mirror products are not only high-performing but also sustainable choices for your projects.