Precision Engineering: Exploring the World of Silver Mirrors

In the demanding landscape of modern industrial and architectural applications, the choice of reflective surfaces is critical. For discerning B2B clients and engineering professionals, the quest for superior clarity, durability, and aesthetic appeal often leads to a specific solution: the silver mirror for sale. Renowned for its unparalleled reflective properties and robust construction, the silver mirror stands as a cornerstone in various sectors, from high-end interiors to advanced optical systems. This comprehensive guide delves into the intricate details of silver mirror technology, covering manufacturing processes, technical specifications, diverse applications, and critical factors for procurement.

Our focus extends beyond mere aesthetics, emphasizing the technical superiority and long-term value that a high-quality silver mirror delivers. We will explore the nuances of what makes a solid silver mirror a premium choice, examine the distinct advantages of surface silvered mirror configurations, and provide insights into sourcing options for specialized requirements like square silver mirrors and those crafted from sterling silver mirrors, ensuring that your investment meets the highest standards of performance and reliability.

Industry Trends and Market Dynamics for Silver Mirrors

The global market for high-performance mirrors, particularly those based on silvering technology, is experiencing steady growth, driven by escalating demand across diverse industries. According to recent market analyses, the architectural and construction sectors remain primary drivers, with a compound annual growth rate (CAGR) projected at 5.5% for decorative and functional mirrors. Beyond traditional applications, emerging trends highlight an increased adoption of silver mirror technology in solar energy systems, advanced optical instrumentation, and smart infrastructure development. The push for energy efficiency and sustainable building materials further amplifies the demand for high-reflectivity, durable mirrors.

Technological advancements are continuously improving the manufacturing process, leading to more environmentally friendly production methods (e.g., lead-free silvering) and enhanced product performance, such as superior resistance to corrosion and abrasion. The versatility of silver mirror products, including bespoke designs like square silver mirrors, caters to evolving design aesthetics and functional requirements, ensuring their sustained relevance in a competitive market. This robust demand underscores the critical need for reliable suppliers of silver mirror for sale that can meet stringent technical specifications and volume requirements.

Manufacturing Process Flow of a Silver Mirror

The production of a high-quality silver mirror is a sophisticated multi-stage process, demanding precision and adherence to strict quality controls. This ensures the mirror's exceptional clarity, reflectivity, and durability, critical for any silver mirror for sale on the market.

Detailed Process Steps:

-

Glass Preparation (Material: High-Quality Float Glass):

The process begins with selecting premium float glass, known for its flat, distortion-free surface. The glass sheets undergo thorough cleaning in multiple stages, including demineralized water rinses, brushing, and hot-air drying, to remove any contaminants that could interfere with silver adhesion. This ensures an impeccably clean substrate, crucial for the quality of the final solid silver mirror.

-

Sensitization:

The clean glass surface is treated with a sensitizing solution, typically stannous chloride. This step creates a uniform layer of tin ions on the glass, which acts as a catalyst, promoting the reduction of silver ions during the subsequent silver deposition phase.

-

Silver Deposition:

This is the core of the silver mirror manufacturing. A silver nitrate solution (the primary material for the reflective layer) and a reducing agent (such as glucose or formaldehyde) are simultaneously sprayed onto the sensitized glass surface. A chemical reaction occurs, reducing the silver ions to metallic silver, which then precipitates and forms a thin, highly reflective coating on the glass. The uniformity and thickness of this layer are meticulously controlled.

-

Copper Plating (Optional, but Common for Durability):

To protect the delicate silver layer from oxidation and abrasion, a layer of copper is often deposited over the silver. This is typically achieved through electroplating using a copper sulfate solution. This robust secondary layer significantly enhances the mirror's service life, especially in high-humidity or corrosive environments.

-

Protective Paint Application:

One or more layers of protective paint are applied over the copper (or directly over the silver in copper-free mirrors). These paints, usually lead-free, provide physical protection against scratching, moisture, and chemical agents, sealing the reflective layers. The paint is applied through rollers or spraying, followed by infrared curing.

-

Drying and Curing:

After paint application, the mirror undergoes a controlled drying and curing process to ensure the paint layers are fully hardened and bonded, providing maximum protection.

-

Inspection and Quality Control:

Each finished silver mirror is rigorously inspected for defects such as scratches, bubbles, stains, and inconsistencies in the reflective coating. Adherence to testing standards like EN 1036 (Glass in building – Mirrors from silvered float glass for internal use), ISO 9227 (Salt Spray Corrosion Tests), and ASTM B117 (Standard Practice for Operating Salt Spray (Fog) Apparatus) is paramount. This ensures every silver mirror for sale meets stringent performance and durability benchmarks.

Target Industries and Advantages:

Target Industries: Architectural (residential & commercial), automotive, furniture, solar power (concentrators), optical instruments, medical devices, petrochemical, metallurgy, water supply & drainage.

Demonstrated Advantages:

- Superior Reflectivity: Up to 90-95% visible light reflectivity, crucial for applications requiring high image fidelity and brightness.

- Enhanced Durability & Corrosion Resistance: Multi-layered protective coatings ensure longevity, even in humid or aggressive environments, making it ideal for the petrochemical or water treatment sectors.

- Energy Saving: In architectural contexts, strategically placed mirrors can enhance natural light penetration, reducing the need for artificial lighting. For solar applications, high reflectivity directly translates to greater energy capture efficiency.

- Aesthetic Versatility: Available in various forms, including square silver mirrors or custom shapes, offering design flexibility for designers and engineers.

Technical Specifications and Performance Parameters

Understanding the precise technical parameters is paramount when selecting a silver mirror for sale for critical applications. The term solid silver mirror typically refers to the robustness and integrity of the silver coating, protected by subsequent layers. For specific optical requirements, a surface silvered mirror (also known as first-surface mirror) may be specified, where the reflective coating is on the front surface of the glass, eliminating secondary reflections, although requiring more delicate handling.

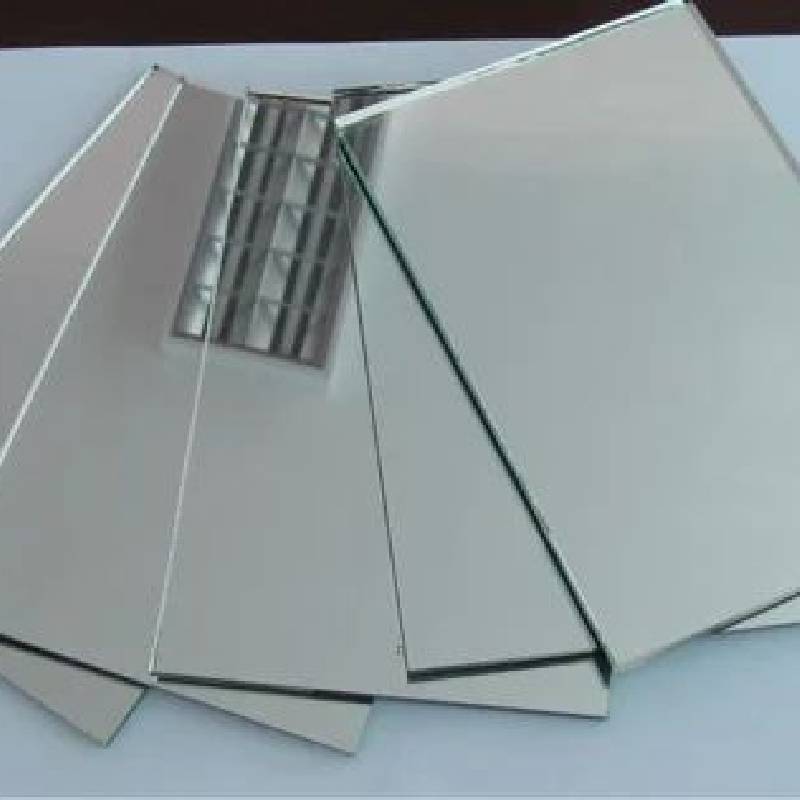

Image: High-precision silver mirror for sale demonstrating superior optical quality.

The table below outlines typical specifications for industrial-grade silver mirror products, providing a benchmark for performance and quality.

Typical Silver Mirror Product Specifications

| Parameter |

Specification/Value |

Testing Standard/Note |

| Reflectivity (Visible Light) |

≥ 90% (Standard); ≥ 94% (High-Performance) |

ISO 9050, CIE S 009/E:2002 |

| Thickness Range |

2mm to 12mm (Custom available) |

Typical industrial range |

| Protective Layers |

Silver layer, Copper layer (optional), 2+ layers of protective paint |

Multi-layer system for enhanced durability |

| Salt Spray Resistance |

> 240 hours (Standard); > 500 hours (High-Durability) |

ISO 9227 (NSS test), ASTM B117 |

| Humidity Resistance |

> 120 hours (Standard); > 200 hours (High-Performance) |

DIN EN ISO 6270-2 (Condensation Test) |

| Lead Content |

≤ 0.009% (Lead-free options available) |

RoHS Compliant |

| Edge Work Options |

Clean cut, polished, beveled, ground |

Customization based on application |

These specifications highlight the robust engineering behind modern silver mirror products. The high reflectivity ensures optimal light utilization, critical for both aesthetic and functional applications. Resistance to environmental degradation, quantified by salt spray and humidity tests, guarantees a long service life, reducing replacement costs and maintenance for industrial clients.

Technical Advantages of Silver Mirrors

Compared to alternative reflective materials, the technical advantages of a silver mirror are substantial and contribute significantly to its widespread adoption in B2B applications.

-

Highest Reflectivity: Silver boasts the highest reflectivity among all metals across the visible spectrum. This translates to unparalleled image clarity and brightness, making silver mirror ideal for applications where accurate reflection is paramount, such as optical instruments, displays, and architectural glazing.

-

Exceptional Durability: The multi-layered protective system—including the copper backing and multiple paint layers—provides superior resistance to moisture, chemicals, and mechanical abrasion. This robust construction ensures that the silver mirror for sale maintains its integrity and optical performance even in challenging industrial environments.

-

Long Service Life: With proper installation and maintenance, a high-quality solid silver mirror can last for decades, minimizing replacement costs and downtime. This longevity is a key factor for long-term infrastructure projects and industrial installations.

-

True Color Rendition: Silver's neutral reflective properties ensure that colors are accurately represented without distortion or tint, which is critical for design, display, and medical imaging applications.

-

Versatility in Customization: From varying thicknesses to bespoke shapes like square silver mirrors, and specialized options such as low-iron glass substrates for enhanced clarity or sterling silver mirrors for maximum purity, manufacturers can tailor silver mirrors to precise client specifications.

Application Scenarios and Real-World Case Studies

The versatility and superior performance of silver mirror products enable their integration into a wide array of demanding applications across various industries.

Typical Applications:

- Architectural and Interior Design: Wall cladding, decorative panels, bathroom mirrors, partitions, and artistic installations.

- Automotive Industry: Rearview mirrors, side mirrors, and interior decorative elements.

- Furniture Manufacturing: Tabletops, cabinet doors, and ornamental accents.

- Solar Energy: Concentrating Solar Power (CSP) systems, where high reflectivity and durability are crucial for efficient energy capture.

- Optical and Scientific Instruments: Telescopes, microscopes, projectors, and various laboratory equipment requiring precise light manipulation. Here, a surface silvered mirror is often chosen to prevent ghosting.

- Retail and Commercial Spaces: Display areas, changing rooms, and creating an illusion of space.

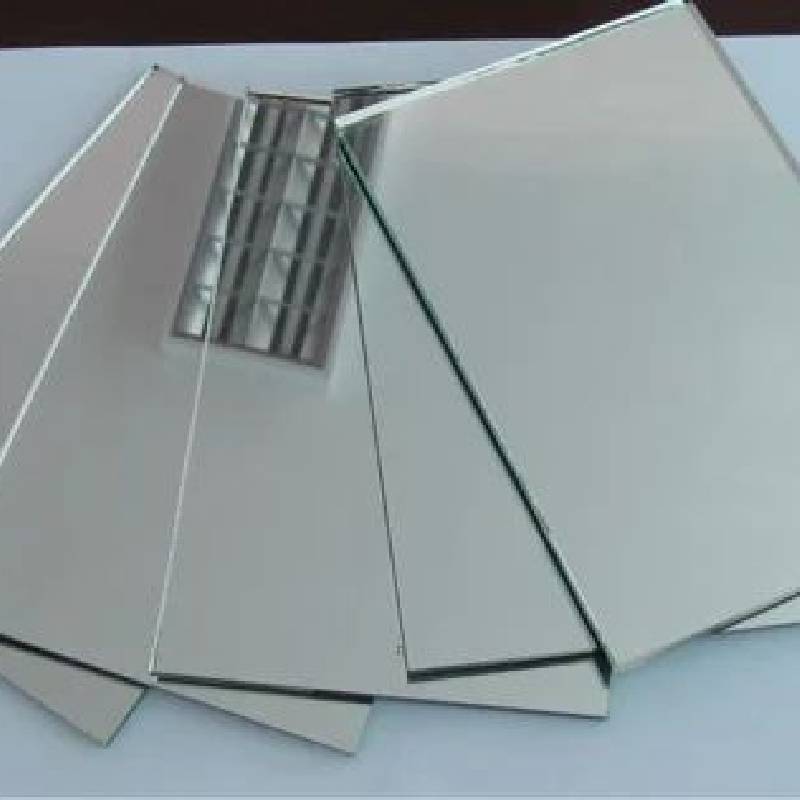

Image: Silver mirror for sale used in a modern architectural facade.

Application Case Studies:

Case Study 1: High-Performance Facade for Commercial Skyscraper

A leading architectural firm sought a highly reflective and durable glass solution for the exterior facade of a new commercial skyscraper in a coastal city. The challenge was to achieve both aesthetic brilliance and robust resistance to salt air corrosion and high humidity. We supplied custom-cut, 6mm thick silver mirror panels, featuring an enhanced anti-corrosion coating and meeting EN 1036 Class A standards. The project utilized over 10,000 square meters of our specialized silver mirror for sale. Post-installation, client feedback highlighted the mirror's exceptional visual clarity, its ability to reflect the city skyline with stunning fidelity, and its proven performance in harsh weather conditions, demonstrating zero visible degradation after three years of exposure. This significantly contributed to the building's LEED certification for energy efficiency by maximizing natural light.

Case Study 2: Solar Concentrators for Industrial Process Heat

An industrial manufacturing client was implementing a Concentrating Solar Power (CSP) system to generate process heat, requiring parabolic mirrors with exceptionally high and stable reflectivity. The operating environment involved significant thermal cycling and outdoor exposure. We provided a bespoke solution of solid silver mirror segments, each precision-cut to specific curvature requirements and boasting >94% specular reflectance. These mirrors were specifically designed as surface silvered mirror components to minimize optical loss. Over a two-year operational period, the mirrors maintained their high efficiency, demonstrating minimal reflectivity degradation (<1%) and excellent resistance to dust and environmental abrasion. This project underscored the critical role of specialized silver mirror technology in achieving sustainable industrial energy solutions.

Customized Solutions for Every Requirement

Understanding that off-the-shelf solutions rarely meet the precise demands of specialized B2B projects, we specialize in providing highly customized silver mirror solutions. Our capabilities extend to tailoring every aspect of the mirror, ensuring perfect integration into your application.

-

Dimensions and Shapes: Beyond standard sizes, we produce custom dimensions, including large-format panels and intricate shapes such as square silver mirrors, circular, elliptical, or complex geometric forms, precisely cut using advanced CNC technology.

-

Thickness and Substrate: We offer a range of glass thicknesses (from 2mm to 12mm) and can utilize various glass substrates, including ultra-clear (low-iron) glass for maximum transparency and clarity, or tempered glass for enhanced safety and strength.

-

Edge Work and Fabrication: Comprehensive edge finishing options are available, including polished edges, beveling, grinding, and drilling, to meet specific installation and aesthetic requirements.

-

Specialized Coatings: For unique environmental or performance demands, we can apply anti-scratch, anti-fog, or hydrophobic coatings. We also offer options for a surface silvered mirror for critical optical applications and even sterling silver mirrors for ultra-high purity reflective surfaces where the highest spectral performance is required.

-

Volume Flexibility: Whether your project requires a single bespoke piece or large-batch production for ongoing supply, our manufacturing facilities are equipped to handle diverse order volumes with consistent quality.

Our engineering team collaborates closely with clients to understand precise needs, providing technical advice and material recommendations to optimize performance and cost-effectiveness for every silver mirror for sale.

Vendor Comparison and Selection Guide

Choosing the right supplier for your silver mirror needs is as critical as the product itself. A reliable vendor not only provides high-quality products but also offers comprehensive support, customization, and logistical efficiency. Here's a comparative overview and a guide to assist in your decision-making process.

Key Factors for Vendor Selection:

- Quality Certifications: Look for ISO 9001, CE, and RoHS compliance. These indicate adherence to international quality management and environmental standards.

- Technical Expertise & R&D: A strong R&D department signals a commitment to innovation and the ability to handle complex technical challenges.

- Customization Capabilities: The ability to produce bespoke sizes, shapes (e.g., square silver mirrors), and specialized coatings is crucial for unique projects.

- Production Capacity & Lead Time: Assess the vendor's capacity to meet your volume requirements and their reliability in delivering within specified lead times.

- Warranty & After-Sales Support: A robust warranty and responsive customer service are indicators of a trustworthy partner.

- Cost-Effectiveness & Value: While price is a factor, focus on the overall value proposition, including product longevity and performance.

Vendor Comparison Table: Premium Silver Mirror Suppliers

| Feature |

TPTOPGLASS (Example) |

Vendor B (General Competitor) |

Vendor C (Niche Specialist) |

| Quality Certifications |

ISO 9001, CE, RoHS, EN 1036, ASTM B117 |

ISO 9001, CE |

ISO 9001, Specialized Optical Certs |

| Customization Options |

Extensive (Sizes, shapes, coatings, edge work, low-iron, surface silvered mirror) |

Moderate (Standard shapes, basic edge work) |

High (Focus on precision optics) |

| Lead Time (Typical) |

15-25 business days (Custom orders) |

20-35 business days |

30-50 business days (Highly specialized) |

| Warranty |

5-year anti-corrosion, 1-year manufacturing defect |

2-year limited |

3-year performance |

| After-Sales Support |

Dedicated project manager, 24/7 online support |

Standard email/phone support |

Technical consultancy |

| Global Shipping |

Yes, experienced in international logistics |

Regional or limited international |

Yes, specialized packaging |

This comparison highlights the importance of comprehensive capabilities, especially when sourcing high-value components like silver mirror for sale. TPTOPGLASS positions itself as a robust partner capable of delivering both standard and highly customized solutions with strong support.

Commitment to Quality, Authoritativeness, and Trustworthiness

At TPTOPGLASS, our commitment to excellence is deeply embedded in every silver mirror we produce. With over 20 years of experience in the glass and mirror industry, we have cultivated a reputation for reliability, precision, and customer-centric service.

-

Authoritative Certifications: All our silver mirror for sale products adhere to rigorous international standards, including ISO 9001 for quality management, CE for European market conformity, and RoHS for hazardous substances restriction. Our mirrors also meet specific industry benchmarks such as EN 1036 for mirror quality and ASTM B117/ISO 9227 for salt spray resistance, ensuring superior durability and performance.

-

Trusted by Industry Leaders: We proudly partner with leading firms across various sectors, including architectural design, automotive manufacturing, and solar energy development. Our long-standing relationships with these authoritative clients underscore our capability to deliver consistent quality and meet stringent project demands.

-

Robust Warranty Commitments: We stand behind the quality of our products with a comprehensive warranty. Typically, our silver mirror products come with a 5-year anti-corrosion warranty and a 1-year warranty against manufacturing defects, providing peace of mind for your investment.

-

Transparent Lead Times and Fulfillment: We understand the importance of timely delivery for B2B projects. Our standard lead time for custom silver mirror orders typically ranges from 15 to 25 business days, depending on complexity and volume. We provide clear communication on production schedules and logistics, supported by a global distribution network to ensure efficient fulfillment worldwide.

-

Dedicated Customer Support: Our commitment extends beyond delivery. We offer professional after-sales support, including technical assistance and a dedicated project manager for large orders. Our team is available to address any inquiries and provide solutions, ensuring a seamless experience from consultation to post-installation.

Frequently Asked Questions (FAQ) about Silver Mirrors

Q1: What is the primary advantage of a silver mirror over an aluminum mirror?

A1: Silver mirror offers significantly higher reflectivity (typically 90-95%) compared to aluminum mirrors (80-88%) across the visible light spectrum. This results in brighter, clearer, and more color-accurate reflections, making silver mirrors preferred for applications requiring superior optical quality and fidelity.

Q2: Are your silver mirrors lead-free and environmentally compliant?

A2: Yes, we offer lead-free silver mirror for sale options that comply with international environmental regulations such as RoHS. Our manufacturing processes prioritize sustainability and minimize environmental impact.

Q3: Can you produce square silver mirrors or other custom shapes?

A3: Absolutely. Our advanced CNC cutting and fabrication capabilities allow us to produce silver mirror in virtually any custom shape, including square silver mirrors, circles, ovals, and complex geometric designs, to meet your precise project specifications.

Q4: What is a surface silvered mirror, and when is it recommended?

A4: A surface silvered mirror (or first-surface mirror) has its reflective coating on the front surface of the glass, preventing "ghost" images caused by reflection from the glass front surface itself. It is recommended for precision optical instruments, projectors, and applications where even minimal secondary reflections are unacceptable.

Q5: How should silver mirrors be cleaned and maintained?

A5: We recommend cleaning with a soft, lint-free cloth and a mild, ammonia-free glass cleaner. Avoid abrasive materials or harsh chemicals that could damage the protective paint layers or the reflective surface. Regular, gentle cleaning will maintain the mirror's pristine appearance and performance.

Q6: What are the typical lead times for a large order of silver mirrors?

A6: Lead times vary based on order volume, customization requirements, and current production schedules. For large or highly customized orders of solid silver mirror products, we typically advise 3-5 weeks from order confirmation to dispatch. We provide detailed lead time estimates with every quotation.

Conclusion: The Enduring Value of Silver Mirrors

The demand for high-quality silver mirror for sale continues to grow, driven by its unmatched optical performance, robust durability, and aesthetic versatility. From precision optical instruments to grand architectural facades, the solid silver mirror remains the preferred choice for engineers, architects, and manufacturers who prioritize clarity, longevity, and superior reflection. With advanced manufacturing processes, adherence to stringent international standards, and a commitment to customized solutions, suppliers like TPTOPGLASS ensure that every silver mirror not only meets but exceeds expectations. Investing in a premium silver mirror is an investment in enduring quality, performance, and aesthetic brilliance for your most critical projects.

References

- ISO 9227:2017. Corrosion tests in artificial atmospheres — Salt spray tests. International Organization for Standardization.

- ASTM B117-19. Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- EN 1036-1:2020. Glass in building — Mirrors from silvered float glass for internal use — Part 1: Definitions, requirements and test methods. European Committee for Standardization.

- CIE S 009/E:2002. Colorimetry. International Commission on Illumination.

- RoHS Directive 2011/65/EU. Restriction of Hazardous Substances. European Union.

- DIN EN ISO 6270-2:2018. Paints and varnishes — Determination of resistance to humidity — Part 2: Condensation (in-cabinet exposure with heated water reservoir). Deutsches Institut für Normung.