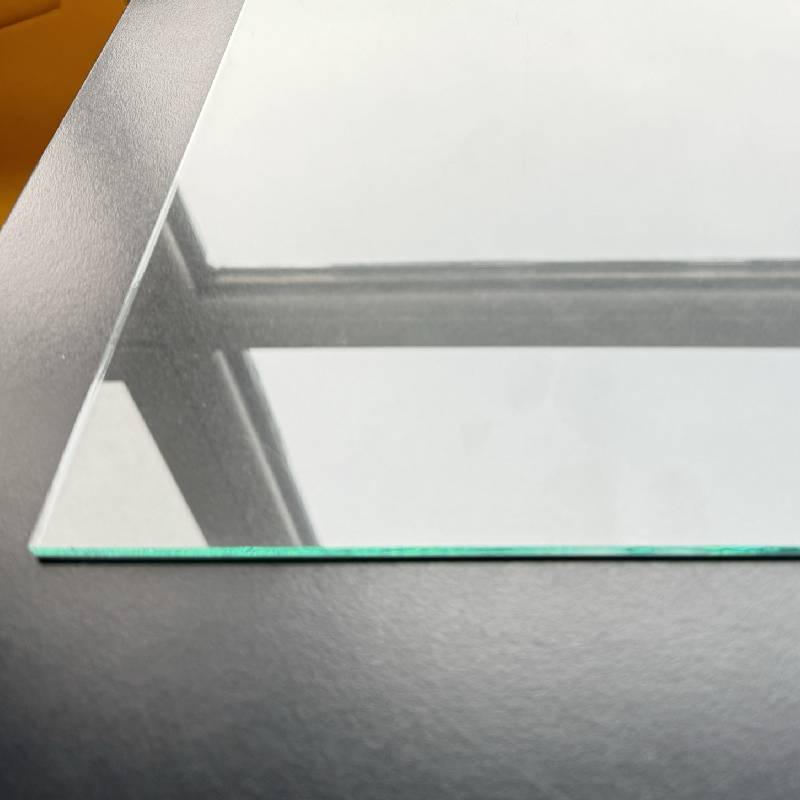

In demanding architectural, solar energy, and display applications, the pursuit of optical clarity and aesthetic purity is paramount. Ultra clear glass, often referred to as low-iron glass, represents a significant advancement over traditional clear float glass. Distinguished by its remarkably low iron oxide content, this specialized glass offers exceptional light transmittance, a neutral color rendition, and virtually eliminates the characteristic green tint often visible in standard glass, especially at thicker profiles. This makes it an indispensable material for projects where transparency and visual fidelity are non-negotiable, influencing everything from energy efficiency in solar panels to pristine visual experiences in high-end displays and sophisticated building facades.

Our commitment to innovation ensures that our ultra clear glass products meet the rigorous demands of modern industry, providing unparalleled performance and aesthetic quality. This article delves into the intricate manufacturing processes, technical specifications, diverse application scenarios, and the inherent advantages that position ultra clear glass at the forefront of advanced material solutions for B2B stakeholders.

The production of ultra clear float glass is a highly refined adaptation of the standard float glass process, specifically engineered to minimize iron content and enhance optical clarity. This specialized manufacturing ensures the superior transparency and reduced color distortion characteristic of extra clear float glass.

The resulting product offers a service life exceeding 25 years under normal conditions, making it ideal for target industries such as architectural glazing, solar energy, display technology, and specialized applications requiring superior optical performance and corrosion resistance, such as those in petrochemical and water treatment facilities.

The market for ultra clear glass is experiencing robust growth, driven by escalating demand in high-performance sectors. Key trends include the expansion of green building initiatives, where high light transmission and improved solar factor contribute to energy-efficient designs. The solar energy sector, particularly for photovoltaic panels and solar thermal collectors, relies heavily on low iron ultra clear glass to maximize energy capture efficiency, with projections indicating a sustained increase in demand mirroring the growth of renewable energy infrastructure.

Technological advancements are also pushing the boundaries, with ongoing research into thinner, stronger, and more durable variants, including enhanced chemical strengthening and advanced surface coatings. The aesthetic appeal of extra clear float glass continues to fuel its adoption in luxury architecture, high-end retail displays, and museum exhibits, where visual clarity and color accuracy are paramount. Geographically, Asia-Pacific remains a dominant market, with significant investment in both production capacity and application development, though demand is strong globally across developed economies.

Our ultra clear float glass adheres to stringent performance metrics, ensuring it meets the exacting requirements of various B2B applications. The reduced iron content is the primary differentiator, leading to superior optical properties compared to standard float glass.

| Parameter | Value for Ultra Clear Glass | Value for Standard Clear Glass (Comparison) |

|---|---|---|

| Light Transmittance (Visible Light, D65, %): | ≥ 91.5% | ≈ 89% |

| Iron Oxide Content (Fe2O3): | < 0.015% | ≈ 0.1% |

| Solar Energy Transmittance (%): | ≥ 89% | ≈ 83% |

| U-value (W/m²K, single pane): | ≈ 5.7 | ≈ 5.7 |

| Density (kg/m³): | 2500 | 2500 |

| Hardness (Mohs Scale): | 6-7 | 6-7 |

| Thickness Range: | 2mm - 19mm | 2mm - 19mm |

These parameters underscore the superior optical performance of ultra clear glass, making it a preferred choice for applications demanding maximal light and solar energy transmission without compromising visual integrity. Our products consistently meet international standards such as EN 572-2 for basic float glass and EN 12150 for thermally toughened safety glass.

The unparalleled clarity and optical performance of ultra clear glass enable its use across a diverse range of high-value applications, offering distinct technical advantages over conventional glass.

When selecting a supplier for ultra clear glass, B2B decision-makers must evaluate vendors on several critical dimensions beyond just price. Quality assurance, technical capabilities, customization options, and after-sales support are paramount for successful project execution and long-term satisfaction.

We specialize in providing tailored ultra clear glass solutions to meet the unique specifications of each project. This includes:

Real-world applications demonstrate the tangible benefits of utilizing ultra clear glass in diverse projects. Our extensive experience with prominent architectural firms and solar integrators underscores our reputation as an authoritative and trusted partner.

Client: A leading global solar energy developer

Challenge: Maximize energy yield from a utility-scale solar farm located in a region with fluctuating sunlight intensity.

Solution: We supplied thousands of square meters of 3.2mm low iron ultra clear glass, tempered for durability and coated with an anti-reflective layer, for their photovoltaic modules. The high light transmittance (>91.5%) of the glass, combined with its resistance to environmental degradation, ensured optimal solar energy capture.

Outcome: The solar farm achieved a 3% increase in overall energy conversion efficiency compared to projections based on standard clear glass, leading to significant long-term operational savings and a faster return on investment. The client praised the consistent quality and reliable lead times, attributing a portion of their project's success to the superior performance of our ultra clear glass.

Client: Renowned architectural firm for a new national museum

Challenge: Design a transparent, luminous facade that allows maximum natural light while ensuring true color representation of interior exhibits and minimizing visual distortion. The facade also needed to meet stringent safety and energy efficiency standards.

Solution: We provided bespoke insulated glass units (IGUs) utilizing 10mm extra clear float glass for both inner and outer panes, further laminated for security. The low iron content ensured an exceptionally neutral color tone, eliminating any green tint. The IGUs also featured a selective low-emissivity coating to manage thermal performance without compromising transparency.

Outcome: The museum's facade became a striking architectural feature, celebrated for its pristine clarity and ability to flood interior spaces with natural, uncolored light. The combination of high VLT and thermal efficiency contributed to the building's LEED Gold certification. The project manager highlighted our technical consultation and precise fabrication capabilities as key to realizing their ambitious design vision.

A: The main difference lies in the iron oxide content. Ultra clear glass has significantly less iron (typically <0.015% Fe2O3) compared to standard clear glass (approx. 0.1% Fe2O3). This reduction eliminates the green tint visible in standard glass, especially at thicker profiles, and results in higher light transmittance (over 91.5% for 4mm thickness).

A: Yes, absolutely. Ultra clear glass is fully processable. It can be tempered to create ultra clear tempered glass for enhanced safety and strength, laminated for security or sound insulation, and used in insulated glass units (IGUs) for thermal performance, all while retaining its superior clarity.

A: Lead times vary based on the complexity, volume, and specific processing requirements of the order. Generally, standard cut sizes can be delivered within 2-4 weeks. Customized and highly fabricated orders, such as complex ultra clear shower glass installations or large-scale architectural projects, may require 6-10 weeks. We recommend contacting our sales team with your project specifications for a precise quote and timeline.

A: We stand behind the quality of our products with a comprehensive warranty against manufacturing defects and material failures for typically 5-10 years, depending on the specific product and application (e.g., IGUs may have a longer seal warranty). Detailed warranty terms are provided with each quotation and order confirmation. We adhere to industry best practices and international quality standards to ensure product longevity and performance.

A: Our dedicated customer support team and technical specialists are available to assist with any post-purchase inquiries, technical guidance, or concerns. We provide comprehensive documentation, installation recommendations, and troubleshooting support. For immediate assistance, please contact us via phone or email, or visit our website for an online support portal.