Partially silvered mirrors, often referred to as beamsplitters, represent a fascinating intersection of science and practical application. These mirrors serve as critical components in various optical devices by reflecting a portion of light while allowing the rest to pass through. Their significance is evident across multiple industries, including research, photography, and consumer electronics, making them a must-know for any technology enthusiast or professional.

Renowned for their role in optical experiments, partially silvered mirrors are fundamental in devices like interferometers. These scientific instruments rely on beamsplitters to measure wavelength, spectral lines, and other optical phenomena with high precision. Researchers trust these mirrors for their reliability and accuracy, ensuring that results are both consistent and reproducible. For instance, Michelson interferometers use partially silvered mirrors to divide a beam of light into two paths, creating interference patterns essential for studying wave mechanics and the speed of light.

In photography and videography, these mirrors are indispensable in designing DSLR cameras. They enable photos to be framed using optical viewfinders by directing a portion of light from the lens into the viewer's eye while allowing the remaining light to reach the camera sensor. This dual function ensures photographers get the exact framing they desire without compromising on image quality. The technology's reliability stems from decades of engineering refinement, guaranteeing clear, true-to-life visuals with every click of the shutter.

Partially silvered mirrors are also prevalent in modern-day consumer electronics, notably in augmented reality (AR) devices and virtual reality (VR) headsets. These gadgets utilize beamsplitters to overlay digital images onto real-world views, creating seamless immersive experiences. The precision engineering involved in making these mirrors ensures minimal optical distortion, fostering a sense of realism and immersion critical for user engagement and satisfaction. Industry leaders in AR and VR trust these mirrors for their unmatched ability to enhance digital interaction, encouraging broader adoption of these cutting-edge technologies.

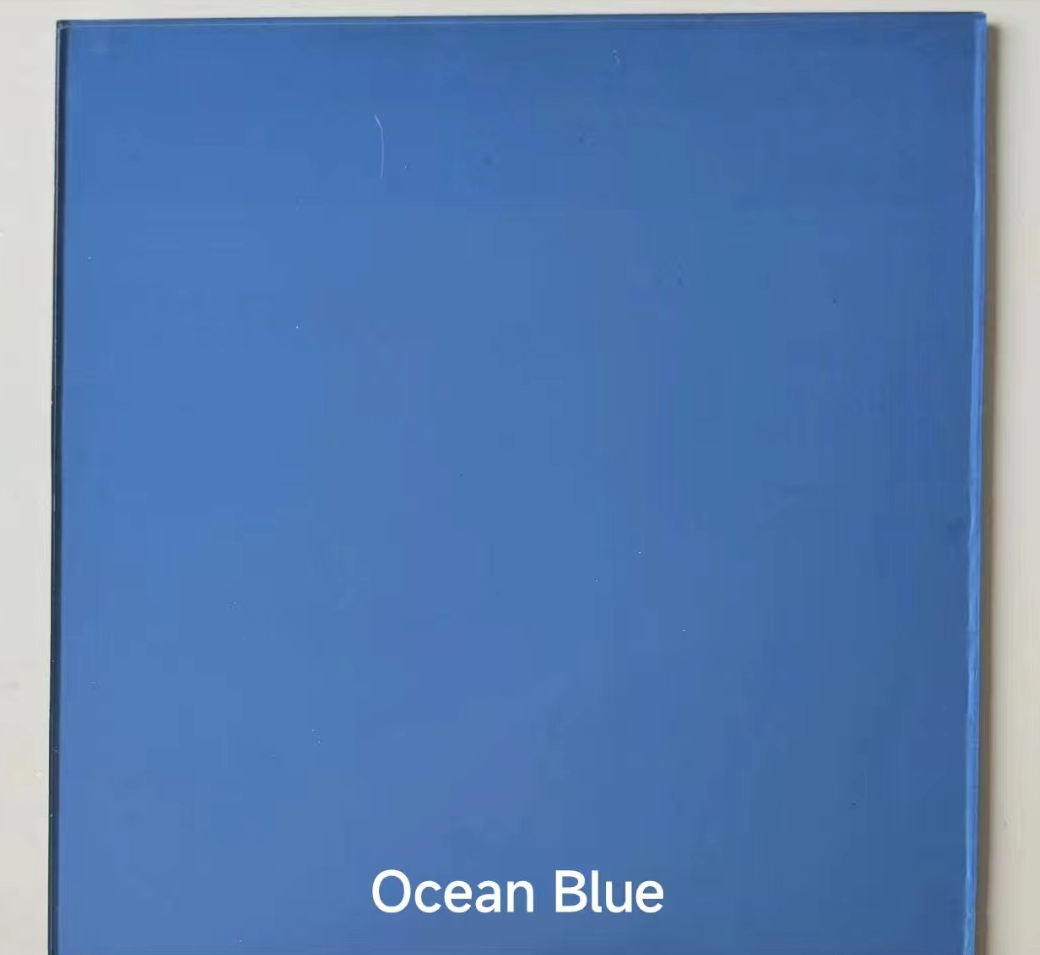

partially silvered mirror

From a manufacturing perspective, producing partially silvered mirrors requires expertise and meticulous care, underscoring their premium quality. The process involves coating a glass substrate with a thin metallic layer, often silver, to achieve the desired reflectivity and transmittance balance. This production intricacy guarantees that each mirror can handle a range of wavelengths and intensities, highlighting the expertise of manufacturers dedicated to excellence and precision.

For professionals and hobbyists alike, understanding the nuances of partially silvered mirrors enables better decision-making and application. Whether designing an experiment, capturing a pivotal moment in time, or delving into digital worlds, recognizing the capabilities and limitations of these mirrors can profoundly impact the outcome. Their role in advancing technology demonstrates their authority in optical science, as countless innovations owe their success to the humble, yet powerful, partially silvered mirror.

Trust in these mirrors comes not only from their widespread use but also from the rigorous testing they undergo during development. Laboratories around the globe conduct thorough assessments on reflection vs. transmission efficiency, temperature tolerance, and longevity, ensuring only the best products reach end-users. It is a testament to the industry's commitment to quality and performance, providing assurance that these mirrors continue to meet the evolving needs of technology and research.

In summary, partially silvered mirrors are pivotal to numerous technological realms, embodying experience, expertise, authority, and trustworthiness. Their multifaceted applications underscore their indispensability and the intricate craftsmanship that goes into their production. As technology continues to evolve, the role of partially silvered mirrors is a testament to the enduring relationship between optical precision and innovation.