In an era increasingly focused on energy efficiency and sustainable building practices, Insulating Glass Units (IGUs), commonly known as double-glazing or triple-glazing, have become indispensable. These advanced glazing solutions are engineered to significantly enhance thermal insulation, reduce noise transmission, and improve overall occupant comfort in a wide array of structures. For businesses and large-scale projects, the demand for high-quality igu glass for sale continues to grow, driven by stringent energy codes, rising energy costs, and a global commitment to environmental responsibility. This strategic shift towards high-performance building materials positions IGUs as a cornerstone of modern, eco-friendly construction, offering long-term operational savings and improved indoor environments for both commercial and residential applications.

The market for insulated glass units for sale is experiencing robust growth, fueled by innovation in glass technology and smart building integration. Architects and developers are increasingly specifying these units for their superior performance characteristics, which contribute directly to certifications like LEED and BREEAM. Beyond thermal benefits, IGUs also provide enhanced security and UV protection, safeguarding interiors from sun damage. Understanding the technical intricacies, manufacturing excellence, and tailored solutions available is paramount for B2B decision-makers looking to invest in optimal glazing for their projects, whether it's a new skyscraper, a large-scale residential complex, or specialized industrial facilities requiring precise environmental control.

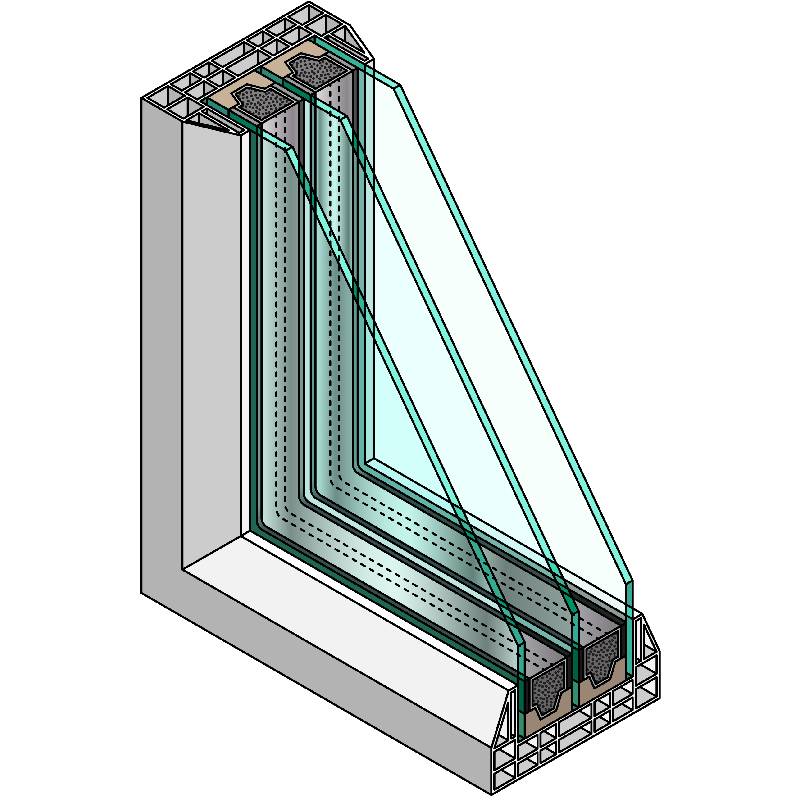

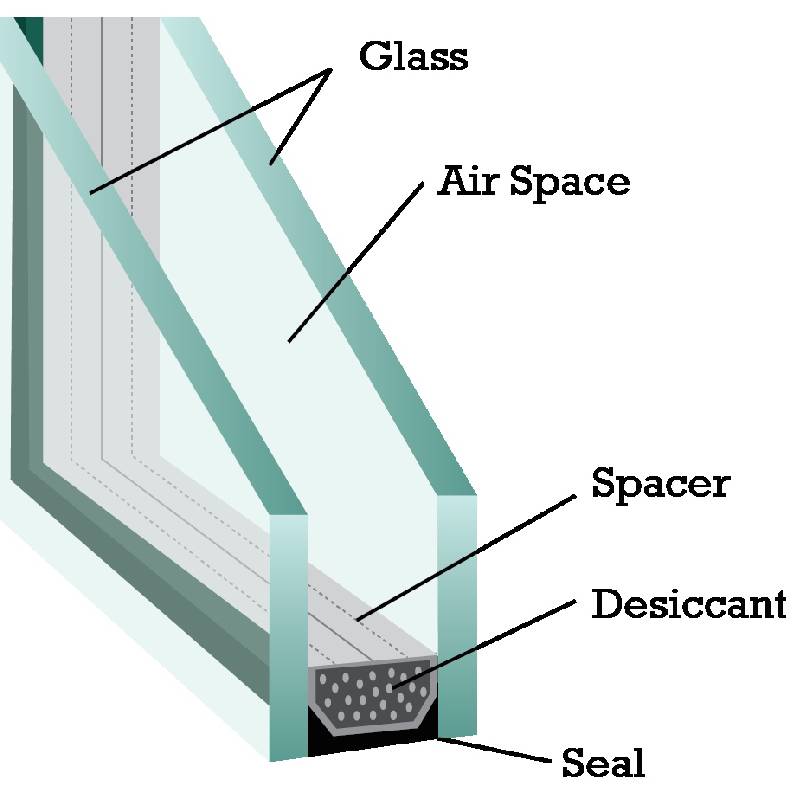

An Insulating Glass Unit (IGU) is fundamentally composed of two or more panes of glass separated by a spacer bar, creating an airtight cavity. This cavity is typically filled with inert gases like argon or krypton to further reduce thermal conductivity. The performance of an igu glass unit is quantified by several critical parameters, which are essential for architects and engineers to consider when selecting glazing. The U-value (or U-factor) measures the rate of heat transfer through the glass, with lower values indicating better insulation. The Solar Heat Gain Coefficient (SHGC) indicates how much solar radiation is admitted through a window, crucial for managing passive solar heating and cooling loads.

Other vital parameters include Visible Light Transmittance (VLT), which determines the amount of daylight passing through; Light to Solar Gain (LSG), a ratio of VLT to SHGC, reflecting daylighting efficiency; and the Condensation Resistance Factor, indicating a window's ability to resist condensation build-up. These parameters are directly influenced by the type of glass (e.g., low-emissivity or Low-E coatings, tempered, laminated), the gas fill, the width of the air space, and the quality of the spacer material (e.g., warm-edge spacers that minimize thermal bridging). Choosing the right combination of these elements for igu glass panels is critical for optimizing energy performance and interior comfort across diverse climatic conditions and architectural demands.

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Glass Thickness | Individual pane thickness | 3mm - 19mm (common: 6mm) |

| Air/Gas Space | Distance between glass panes | 6mm - 20mm (common: 12-16mm) |

| U-value (W/m²K) | Thermal Transmittance (lower is better) | 1.1 (air fill, Low-E) to 0.5 (triple, argon, Low-E) |

| SHGC | Solar Heat Gain Coefficient (0-1) | 0.25 - 0.70 (Low-E typically 0.25-0.45) |

| VLT (%) | Visible Light Transmittance | 50% - 85% |

| Sound Reduction (dB) | Decibels reduced (higher is better) | 25 - 40+ (depending on specific configurations) |

| Lifespan | Expected functional life of the unit | 15 - 25 years (or more with proper installation) |

The production of high-quality igu glass involves a meticulous multi-stage process, beginning with the careful selection of raw glass materials. This ensures optimal clarity, strength, and the ability to accept specialized coatings. The primary stages typically include precision cutting, edge working, and thorough washing of the glass panes. Each pane is cut to exact dimensions, and edges are often ground or polished to ensure safety and improve sealing performance. Prior to assembly, the glass surfaces undergo a rigorous cleaning process to remove any contaminants, which is crucial for maintaining optical clarity and ensuring proper adhesion of sealants.

Following cleaning, a spacer bar, usually made of aluminum or a "warm edge" material, is accurately positioned between the glass panes. This spacer contains a desiccant, such as molecular sieve, to absorb any moisture within the air gap, preventing internal condensation. The next critical step is primary sealing, where a flexible sealant (e.g., polyisobutylene or PIB) is applied along the edges of the spacer, creating a robust, airtight bond. This initial seal is vital for maintaining the integrity of the gas fill and preventing moisture ingress. Subsequently, a secondary structural sealant, often silicone or polysulfide, is applied to the outer perimeter of the unit, providing long-term durability, structural stability, and protection against environmental factors. This comprehensive sealing process ensures the longevity and consistent performance of the igu glass unit.

Crucially, if an inert gas like argon or krypton is specified, it is filled into the cavity before the secondary seal is fully cured. This gas replacement significantly enhances the thermal performance of the unit. Throughout the entire manufacturing process, rigorous quality control measures are implemented. These include adherence to international standards such as ISO 9001 for quality management and ANSI standards for glass performance and safety. Each igu glass for sale unit undergoes stringent visual inspections, dimensional checks, and performance tests, including dew point testing and gas fill verification, to ensure it meets specified U-values, SHGC, and overall durability. The expected lifespan of a well-manufactured IGU is typically 15 to 25 years, depending on environmental conditions and installation quality.

The adoption of Insulating Glass Units delivers multifaceted advantages, making them a preferred choice across various sectors. The primary benefit lies in superior thermal insulation, significantly reducing heat transfer through windows. This translates directly into substantial energy savings for heating in colder climates and cooling in warmer regions, lowering operational costs for commercial buildings, residential complexes, and industrial facilities. For instance, an IGU can reduce heat loss by over 50% compared to a single pane of glass, dramatically impacting the energy footprint of large structures. Beyond energy efficiency, igu glass panels offer enhanced acoustic insulation, effectively dampening external noise from traffic, construction, or urban environments, creating quieter and more productive indoor spaces.

Furthermore, the sealed nature of an IGU prevents internal condensation, maintaining clear views and inhibiting mold growth. They also provide increased security against forced entry and offer improved UV protection, safeguarding interior furnishings and occupants from harmful rays. Typical application scenarios for high-performance igu glass for sale are incredibly diverse. In the commercial sector, they are crucial for office buildings, hotels, and retail spaces, where energy efficiency, comfort, and aesthetics are paramount. In residential architecture, they enhance living quality, reduce utility bills, and increase property value. Industrial applications include climate-controlled warehouses, cleanrooms, and specialized facilities where stable internal temperatures and minimal environmental impact are critical, demonstrating their versatility and robust performance.

When sourcing insulated glass units for sale, B2B decision-makers must conduct a thorough comparative analysis of manufacturers, focusing on technical capabilities, quality assurance, and customization options. Key factors for evaluation include a manufacturer's adherence to international standards (e.g., ISO, CE, ASTM), their production capacity for large-scale projects, and their experience in handling complex, bespoke designs. A reputable supplier will offer a wide range of glass types (low-E, tempered, laminated, tinted), gas fills (argon, krypton), and spacer options (aluminum, warm edge) to meet specific project requirements, ensuring optimal thermal, acoustic, and aesthetic performance.

Customization is a significant advantage in the IGU market, allowing for tailored solutions that precisely fit unique architectural demands. This includes custom dimensions, unusual shapes, specialized coatings for solar control or privacy, and integration with building management systems. Furthermore, a strong supplier will provide comprehensive technical support, from initial design consultation to post-delivery assistance. Look for manufacturers with a proven track record, demonstrated through detailed case studies and positive client testimonials, especially those showing significant energy savings or enhanced comfort in similar projects. Transparent communication regarding lead times, delivery logistics, and post-purchase support is also crucial for successful project execution when purchasing igu glass panels.

Building trust with B2B clients requires unwavering commitment to quality, transparent operational processes, and robust customer support. When considering igu glass for sale, inquire about the manufacturer's quality management certifications, such as ISO 9001:2015, which assures consistent product quality. Ask for detailed performance reports and test certificates, especially concerning U-value, SHGC, and sound insulation, from independent testing laboratories. A reputable supplier will readily provide these documents, reinforcing the authority and reliability of their products. Furthermore, clarity on delivery cycles, typical lead times for custom orders, and logistical capabilities for large volume shipments are essential for project planning and execution.

Most manufacturers offer a 5-10 year warranty against seal failure, which would manifest as fogging between the glass panes. Higher-quality units and specialized applications may come with extended warranties.

Inert gases like argon or krypton are denser than air, which significantly reduces convective and conductive heat transfer within the sealed cavity, leading to a lower U-value and improved energy efficiency. Argon is common, while krypton offers even better performance but at a higher cost.

While some companies offer "de-fogging" services, these are generally not recommended for long-term solutions as they do not restore the unit to its original sealed, gas-filled condition. In most cases, a failed IGU requires replacement of the entire unit to restore thermal performance and clarity.

IGUs are low-maintenance. Regular cleaning of the glass surfaces with standard window cleaner is sufficient. Inspect seals periodically for any signs of damage or degradation, though issues are rare in high-quality units.

A strong customer support framework, encompassing technical assistance, responsive communication, and efficient after-sales service, is a hallmark of a trustworthy supplier. Partnerships with companies that provide comprehensive project management support, from specification to installation guidance, minimize risks and ensure that projects are completed on time and within budget, cementing long-term client relationships.

Investing in high-quality Insulating Glass Units represents a strategic decision for any B2B stakeholder involved in construction, architecture, or industrial development. The benefits extend far beyond initial cost, encompassing significant energy savings, enhanced occupant comfort, superior acoustic performance, and improved building longevity. With the increasing global emphasis on sustainability and energy efficiency, the demand for advanced glazing solutions like igu glass for sale will only intensify. Partnering with a manufacturer that demonstrates expertise, adheres to stringent quality standards, offers comprehensive customization, and provides robust customer support is crucial for realizing the full potential of these indispensable building components.

As urban landscapes evolve and environmental regulations tighten, the role of IGUs as a foundational element of high-performance envelopes becomes ever more critical. Their ability to deliver measurable improvements in thermal comfort and energy consumption solidifies their position as an essential component for future-proof building projects, contributing to both economic efficiency and environmental stewardship.