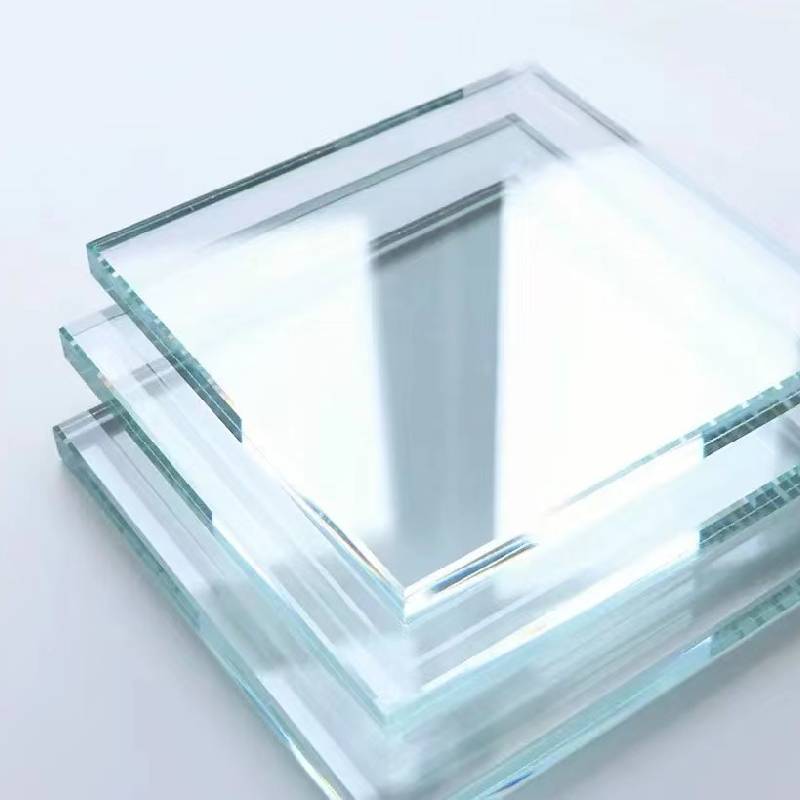

In the rapidly evolving landscape of architectural design, solar energy, and display technologies, the demand for materials offering unparalleled transparency and optical performance has never been higher. This pivotal requirement is precisely met by ultra clear glass, a premium product distinguished by its remarkably low iron content. Unlike conventional float glass, which often exhibits a greenish tint due to higher iron oxide levels, extra clear float glass minimizes this inherent discoloration, resulting in a product that delivers superior light transmittance and neutral color fidelity. This technological leap ensures that natural light is maximally harnessed, colors are rendered authentically, and visual distortions are virtually eliminated. The transformative impact of this material extends across various sectors, from creating breathtaking, virtually invisible facades that seamlessly blend interiors with their surroundings, to enhancing the efficiency of photovoltaic panels by allowing more solar radiation to reach the active cells. Its unique properties make it an indispensable component for architects aiming for aesthetic purity, engineers striving for peak energy performance, and manufacturers demanding the highest optical clarity for their sophisticated products. The meticulous manufacturing processes involved in producing low iron ultra clear glass are key to its exceptional performance, setting it apart as a high-value material in an increasingly transparent world. Understanding the intricate details of its production, technical specifications, and diverse applications is crucial for any B2B decision-maker looking to invest in leading-edge materials for high-performance projects.

The creation of ultra clear float glass is a testament to precision engineering, fundamentally differentiating it from standard glass production. The core principle lies in the use of high-purity silica sand, alongside other raw materials such as soda ash, limestone, and dolomite, all meticulously selected for their exceptionally low iron oxide content. This critical selection minimizes the ferrous impurities (Fe2O3) responsible for the green tint observed in ordinary glass. The manufacturing process commences with melting these carefully proportioned raw materials in a furnace at temperatures exceeding 1700°C, ensuring a homogenous molten glass batch. This molten glass then flows onto a bath of molten tin, a technique known as the float process. On this perfectly flat surface, the glass ribbon forms and achieves an exceptionally uniform thickness and fire-polished surfaces on both sides, requiring no further grinding or polishing. Crucially, as the glass ribbon slowly cools and solidifies within the annealing lehr, internal stresses are systematically relieved, enhancing its strength and optical clarity. Post-annealing, the large sheets of ultra transparent glass are cut to size. Throughout this entire process, stringent quality control measures are implemented. Adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management is paramount. Specific optical properties, including visible light transmittance (VLT) and solar heat gain coefficient (SHGC), are rigorously tested. The glass undergoes visual inspection for defects, dimensional accuracy checks, and sometimes even spectrophotometric analysis to confirm its low iron content and color neutrality. This robust manufacturing protocol ensures a superior product that meets the demanding requirements for applications where maximum transparency and minimal distortion are non-negotiable, offering a typical service life exceeding 25-30 years in stable environmental conditions, making it ideal for long-term installations in diverse sectors.

The technical superiority of ultra clear glass is quantified by several key performance indicators that distinguish it significantly from standard clear glass. The most prominent characteristic is its exceptionally high visible light transmittance (VLT), which can exceed 91% for a 3mm thickness, compared to approximately 88% for conventional glass. This higher VLT directly translates to brighter interiors and more accurate color representation, crucial for applications like art galleries, museums, and high-end retail spaces where true color rendering is paramount. Furthermore, its lower iron content, typically less than 0.01%, virtually eliminates the characteristic greenish tint, ensuring a truly neutral edge appearance even in thicker laminations. This optical purity significantly reduces solar heat gain, contributing to energy efficiency in buildings by minimizing the need for artificial lighting and reducing cooling loads. The solar heat gain coefficient (SHGC) is optimized, allowing beneficial daylight in while blocking excessive heat. When processed into ultra clear tempered glass, its mechanical strength is dramatically increased, making it up to five times stronger than annealed glass of the same thickness, thus providing enhanced safety and durability for structural glazing, balustrades, and shower enclosures. This enhanced strength combined with its superior clarity makes it an ideal choice for safety-critical and aesthetically driven projects. Moreover, its superior chemical stability makes it more resistant to environmental degradation and surface corrosion over time, ensuring long-term performance and reduced maintenance, particularly in humid or coastal environments. The combination of its pristine aesthetics, exceptional light transmission, and robust physical properties positions ultra clear glass as the material of choice for discerning professionals who prioritize both performance and visual excellence in their designs.

| Parameter | Ultra Clear Glass (3mm) | Standard Clear Glass (3mm) | Benefit of Ultra Clear |

|---|---|---|---|

| Visible Light Transmittance (VLT) | >91% | ~88% | Brighter interiors, true color rendering |

| Iron Content (Fe2O3) | <0.01% | ~0.10% | Eliminates green tint, neutral edge |

| Solar Heat Gain Coefficient (SHGC) | ~0.88 | ~0.85 | Improved energy efficiency (when paired with coatings) |

| Color Rendering Index (CRI) | Excellent | Good | More accurate perception of colors |

| UV Transmittance | Higher | Lower | Beneficial for solar applications |

The exceptional clarity and performance characteristics of ultra transparent glass have made it an indispensable material across a broad spectrum of industries, revolutionizing how light, space, and energy are managed. In the architectural sector, it is the preferred choice for sophisticated facades, skylights, and interior partitions in high-end commercial buildings, luxury residences, and public institutions like museums and art galleries. Its ability to maximize natural light ingress significantly reduces reliance on artificial lighting, contributing to LEED certification and fostering healthier, more productive indoor environments. Furthermore, when used in display cases or shopfronts, it ensures products are viewed with absolute color fidelity and without distortion, enhancing consumer engagement. In the rapidly expanding solar energy industry, ultra clear glass serves as the crucial cover plate for photovoltaic (PV) modules and solar thermal collectors. Its superior light transmittance directly boosts the efficiency of solar panels, allowing more sunlight to reach the solar cells and convert into electricity, thereby increasing energy yield and accelerating ROI for solar farm developers and residential installers alike. Beyond these major applications, this specialized glass finds its place in high-precision industries. It is utilized in greenhouse construction where optimal light penetration is vital for plant growth, in specialized furniture and shelving where aesthetic purity is paramount, and even in sophisticated optical instruments and display technologies requiring precise visual clarity. Its inherent chemical stability also makes it suitable for environments where exposure to certain elements might degrade standard glass, ensuring longevity and consistent performance across diverse and demanding scenarios. The versatility and high-performance profile of ultra clear glass continue to drive innovation, pushing boundaries in design, energy efficiency, and functional clarity.

Recognizing that no two projects are identical, leading manufacturers of ultra clear glass offer comprehensive customization solutions to meet specific design and performance requirements. This includes variations in thickness, ranging from a slim 3mm for lightweight applications to robust 19mm for structural glazing or high-impact areas. Beyond standard dimensions, bespoke cutting to precise shapes, sizes, and edge work (e.g., polished, beveled, or drilled) is routinely offered. Furthermore, the glass can be processed with various functional coatings, such as low-emissivity (low-e) coatings for enhanced thermal insulation, anti-reflective coatings to minimize glare in display applications, or self-cleaning coatings for exterior facades, extending its versatility. For enhanced safety and security, ultra clear glass can be heat-strengthened, tempered, or laminated, creating products like ultra clear tempered glass or multi-layered safety glass that adheres to international safety standards such as ANSI Z97.1 and EN 12150. Choosing the right manufacturer is crucial; look for established companies with a proven track record, extensive certifications (e.g., ISO 9001, CE, ASTM), and transparent quality control processes. A reputable supplier will not only provide high-quality products but also offer expert technical support throughout the project lifecycle, from initial consultation and specification development to logistics and post-installation support. Their ability to deliver consistent quality, adhere to strict timelines, and offer tailored solutions is paramount. For example, our company, with over a decade of experience in the glass industry, consistently delivers high-precision ultra clear glass solutions, evidenced by our portfolio of successful projects and long-term client partnerships globally. Our commitment to innovation and customer satisfaction ensures that every project receives optimal material selection and processing, guaranteeing superior aesthetics and performance.

Building confidence with B2B clients requires absolute transparency regarding product capabilities, logistical processes, and after-sales support. Below are answers to common questions about ultra clear glass, detailing our commitment to customer satisfaction:

Our commitment to delivering not just a product, but a complete solution, underpins every interaction. We believe that a strong partnership is built on trust, quality, and reliable support, ensuring your projects benefit from the very best in glass technology.

The trajectory of ultra clear glass is intricately linked with global trends toward sustainability, energy efficiency, and enhanced user experience. As architectural design continues to favor transparency and natural light, the demand for ultra clear float glass is projected to grow significantly. Innovations are focusing on integrating smart technologies, such as dynamic tinting or embedded sensors, without compromising its pristine clarity. Furthermore, advancements in coating technologies are enabling ultra transparent glass to offer improved thermal insulation (U-value reduction) and solar control (lower SHGC) properties, making buildings even more energy-efficient. The solar industry's relentless pursuit of higher module efficiency continues to fuel research into optimizing the light transmission properties of cover glass, with low iron ultra clear glass remaining at the forefront of this development. Its role in enhancing renewable energy generation underscores its environmental credentials. Beyond performance, the manufacturing process itself is becoming more sustainable, with efforts to reduce energy consumption, minimize waste, and increase the use of recycled cullet (recycled glass) while maintaining the ultra-clear purity. This commitment to sustainable production practices ensures that the environmental footprint of ultra clear glass is continually minimized, aligning with corporate social responsibility goals and global environmental targets. Its inherent durability and long service life also contribute to sustainability by reducing the need for frequent replacement, thereby conserving resources. As urban landscapes become denser and the need for natural light and connection to the outdoors becomes more critical, the strategic application of ultra clear glass will play a pivotal role in shaping healthier, more efficient, and aesthetically superior built environments for the future. The continued investment in R&D promises to unlock even greater potential for this remarkable material.