The Art and Craft of Patterned Glass Factory

In the heart of a bustling industrial landscape lies a patterned glass factory, a place where creativity meets craftsmanship, resulting in exquisite glass pieces that serve both aesthetic and practical purposes

. Patterned glass, known for its unique textures and designs, has graced windows, doors, and even decorative items for centuries. The factory operates as a hub of innovative glass-making techniques, blending tradition with modern technology.Upon entering the factory, visitors are often greeted by the rhythmic sound of machinery alongside the soft chime of glass pieces being meticulously handled. The factory employs a team of skilled artisans and technicians, each specializing in different aspects of glass production. From the initial melting of raw materials to the final inspection of finished products, every step in the process is crucial in creating high-quality patterned glass.

The journey of crafting patterned glass begins with the selection of raw materials, typically silica sand, soda ash, and limestone. These materials are carefully measured and combined before being heated to extreme temperatures in a furnace. The molten glass is then poured into molds that shape it into various forms. This is where the magic of patterning happens. Artisans use techniques such as embossing, rolling, and etching to create intricate designs on the glass surface.

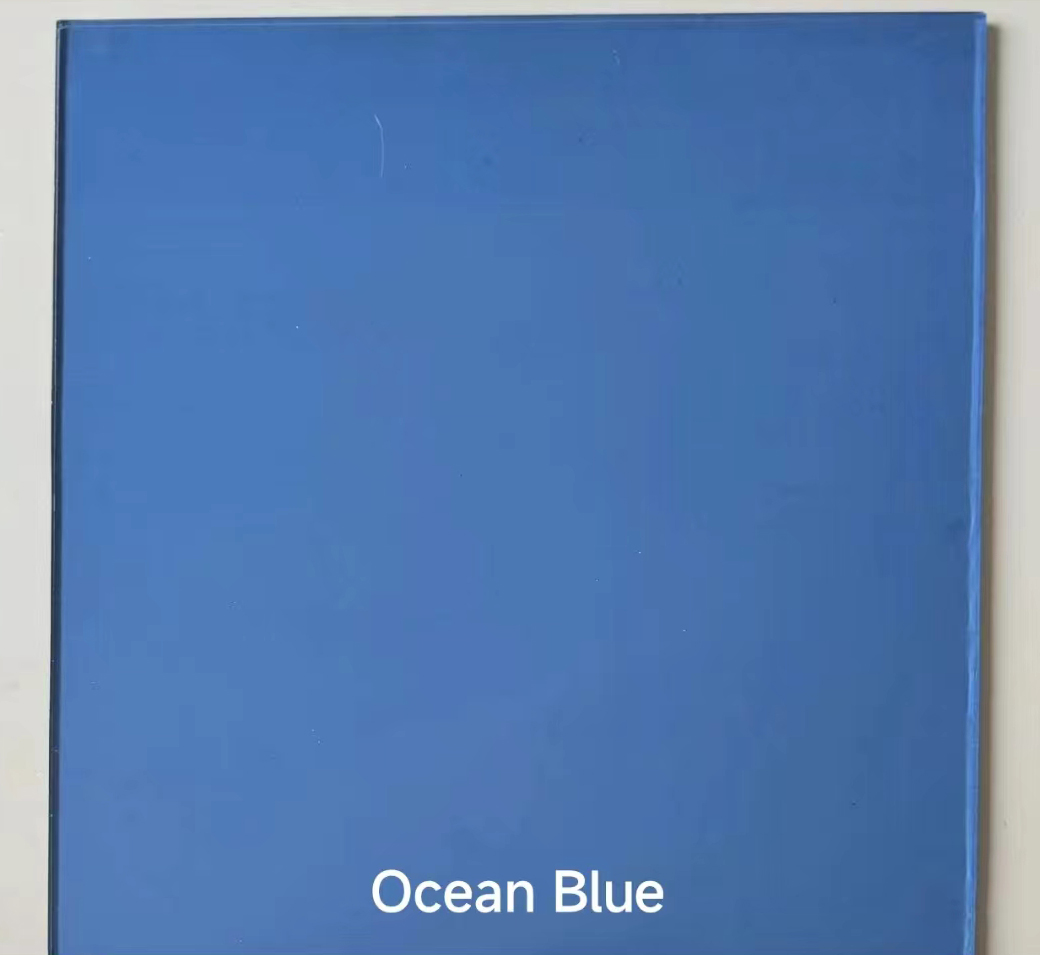

One of the most popular techniques used in the factory is the application of a frosted effect, achieved through sandblasting. This method not only adds a decorative touch but also creates privacy without sacrificing natural light. Another technique involves applying colored glass layers, providing depth and richness to the finished product. The possibilities are endless, making patterned glass a versatile choice for architects and designers.

Quality control is a top priority in the factory, ensuring that each piece meets strict standards before it is shipped to clients. Each product undergoes rigorous testing for durability and clarity. The commitment to excellence has earned the factory a reputable name within the industry, with clients ranging from local businesses to international distributors.

Moreover, sustainability practices are increasingly becoming a focal point for the factory. By recycling glass waste and using energy-efficient processes, the factory not only reduces its environmental footprint but also sets a standard for responsible manufacturing in the glass industry.

In conclusion, the patterned glass factory is not just a place of production; it is a realm where art intertwines with industry. Each piece of patterned glass tells a story of creativity, skill, and dedication, making it a cherished addition to any space. As technology continues to evolve, the factory remains committed to preserving the artistry of glass-making while embracing innovation for the future.