The Glass Manufacturing Industry An Overview

The glass manufacturing industry is a vital sector that plays a significant role in various applications, ranging from construction and automotive to consumer goods and electronics. With a history spanning thousands of years, glass has evolved from a luxury item to an essential material in everyday life. Today, the industry is characterized by a diverse array of products, innovative technologies, and a commitment to sustainability.

Historical Context

The art of glass manufacturing dates back to around 2000 BC, with ancient civilizations, such as the Egyptians and Mesopotamians, pioneering early techniques. Initially, glass was primarily used for decorative purposes, including jewelry and intricate vessels. As knowledge and technology advanced, glass-making techniques spread across Europe and Asia, leading to the development of stained glass windows, glass blowers, and eventually the modern glass production methods we recognize today.

Modern Glass Manufacturing Processes

Today, glass manufacturing involves a variety of processes, each tailored to specific types of glass and desired characteristics. The primary raw materials for glass production include silica sand, soda ash, and limestone. These components are melted in a furnace at high temperatures, typically exceeding 1,700 degrees Celsius. Once melted, the glass can be molded, blown, or formed into different shapes.

Key processes in modern glass manufacturing include

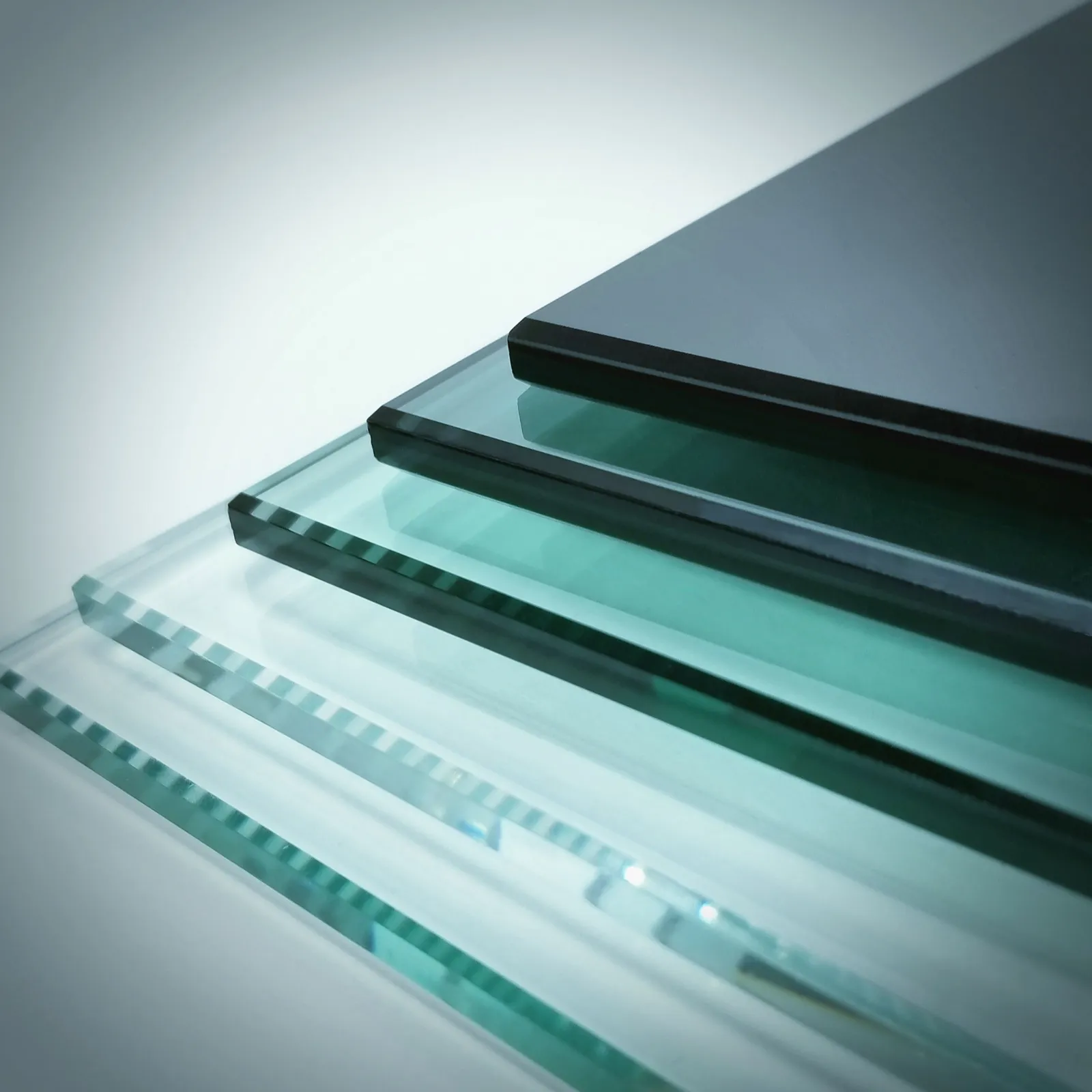

1. Float Glass Production This method is commonly used for making flat glass for windows and mirrors. Molten glass is floated on molten tin, resulting in a smooth, polished surface.

2. Blown Glass Production This traditional technique involves inflating molten glass into a bubble, which can then be shaped into various forms. It is often used for creating artistic and decorative glass pieces.

3. Pressed Glass Production In this method, glass is heated and then pressed into molds to create specific shapes, commonly found in container glass production.

4. Glass Fiber Production Glass fibers are produced by drawing molten glass into thin threads, which are then used in composites and insulation materials.

Applications and Market Trends

The glass manufacturing industry serves numerous sectors, including construction, automotive, consumer goods, electronics, and renewable energy. In construction, glass is utilized in facades, windows, and skylights, enhancing both aesthetics and energy efficiency. The automotive sector employs specialized glass for windshields and sunroofs, contributing to vehicle safety and comfort.

In recent years, the demand for smart glass—glass that can change its properties based on environmental conditions—has surged. This innovation presents exciting opportunities for energy conservation and modern architectural design.

Sustainability Challenges

While glass is a versatile and valuable material, the glass manufacturing industry faces significant sustainability challenges. Traditional glass production is energy-intensive and can result in high carbon emissions. However, many manufacturers are now adopting more sustainable practices, including

- Utilizing recycled glass (cullet) in production to reduce raw material consumption and energy use. - Investing in renewable energy sources to power manufacturing facilities. - Implementing lean manufacturing practices to minimize waste and improve efficiency.

Conclusion

The glass manufacturing industry encompasses a wide range of processes and products that are integral to modern life. With ongoing advancements in technology and a growing emphasis on sustainability, the future of glass manufacturing promises to be innovative and environmentally conscious. As the industry continues to evolve, it will be essential for manufacturers to balance economic growth with responsible practices, ensuring that glass remains a fundamental material for generations to come.