Modern Aluminum Alloy Mirrors A Reflection of Innovation

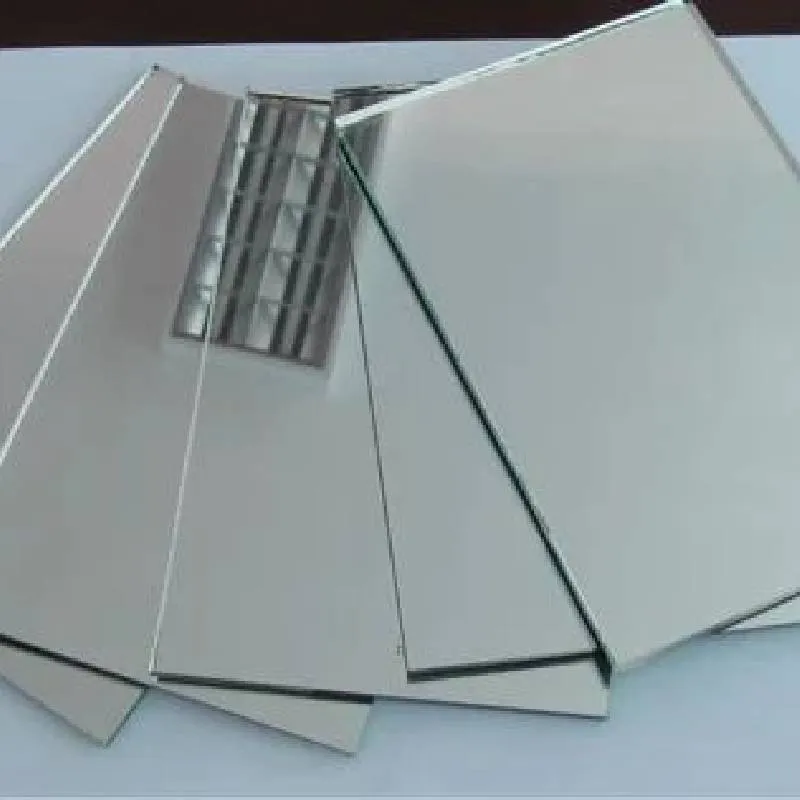

In contemporary design and engineering, the material used in various applications often plays a critical role in both functionality and aesthetic appeal. Among these materials, aluminum alloys have emerged as a popular choice, particularly in the manufacturing of mirrors. Aluminum alloy mirrors combine the lightweight and corrosion-resistant properties of aluminum with advanced technology to create products that serve a multitude of purposes across different industries.

One of the most significant advantages of aluminum alloy mirrors is their remarkable weight-to-strength ratio. Traditional mirrors, especially those made with glass, can be heavy and cumbersome, making installation and handling challenging. In contrast, aluminum alloy mirrors are incredibly lightweight, allowing for easier transportation and installation. This feature is particularly advantageous in industries such as automotive, aerospace, and architecture, where reducing weight without sacrificing quality is paramount.

Moreover, aluminum alloys exhibit excellent corrosion resistance owing to the natural oxide layer that forms upon exposure to air. This inherent property is particularly beneficial for mirrors used in outdoor settings or harsh environments where exposure to moisture and chemicals can be detrimental. By utilizing aluminum alloy mirrors, manufacturers can ensure longevity and durability, reducing maintenance costs and increasing the lifecycle of the products. This makes them an excellent choice for applications such as solar reflectors, which are exposed to the elements and require materials that can withstand the rigors of outdoor conditions.

Another area where modern aluminum alloy mirrors shine is in their reflective quality. Sophisticated coating techniques can enhance the reflectivity of aluminum, allowing these mirrors to achieve high-performance standards comparable to traditional glass mirrors. The advanced surface finishing processes, including anodizing and applying specialized reflective coatings, further enhance their efficiency. As a result, aluminum alloy mirrors are increasingly being used in high-precision applications, such as in scientific instruments, telescopes, and optical devices, where superior reflectivity is essential.

The aesthetic appeal of aluminum alloy mirrors cannot be overlooked either. With advancements in manufacturing technology, these mirrors can be produced in various shapes and finishes, providing designers with versatile options. Whether it’s for decorative purposes in interior design or functional applications in automotive or aerospace, the ability to customize aluminum alloy mirrors enables them to fit seamlessly into contemporary designs.

Additionally, the sustainability factor associated with aluminum alloys is becoming increasingly relevant in today’s environmentally conscious market. Aluminum is highly recyclable, allowing manufacturers to minimize waste and promote eco-friendly practices. When end-of-life aluminum alloy mirrors are disposed of, they can be recycled and repurposed into new products, thus contributing to a circular economy.

In conclusion, modern aluminum alloy mirrors are a testament to the advancements in materials science and manufacturing technology. Their lightweight nature, exceptional durability, superior reflectivity, aesthetic flexibility, and sustainability make them an ideal choice for a broad array of applications. As industries continue to innovate and seek solutions that balance performance and environmental impact, aluminum alloy mirrors will undoubtedly play a pivotal role in shaping the future of reflective surfaces, proving that innovation and practicality can go hand in hand. Whether used in everyday products or high-tech applications, they exemplify the intersection of design and functionality in the modern world.