Understanding Plain Float Glass Characteristics and Applications

Plain float glass, a ubiquitous material in modern construction and design, has become an essential component in various applications ranging from architecture and interior design to automotive and electronics. The production of plain float glass involves a simple yet effective process that results in a flat glass product characterized by its clarity, uniform thickness, and smooth surface.

Production Process

The manufacturing of plain float glass begins with the careful selection of raw materials, primarily silica sand, soda ash, and limestone. These raw materials are heated in a furnace to form molten glass. The key step in the production process is the floating of the molten glass. This is where the float glass gets its name. The molten glass is poured onto a bed of molten tin, exploiting the differences in density to create a smooth, flat surface. The glass spreads out evenly over the tin, forming a ribbon of glass that is then cooled and cut into manageable sheets.

This float process not only ensures a high level of clarity and smoothness regarding the glass surface, but it also allows for consistent thickness across the entire sheet. The resulting product can vary in thickness, generally ranging from 2 mm to 12 mm, catering to different demands in various industries.

Properties of Plain Float Glass

One of the standout characteristics of plain float glass is its remarkable optical clarity

. It allows visible light to pass through with minimal distortion, making it suitable for applications where clarity is critical, such as windows and display cases. Additionally, plain float glass possesses excellent thermal stability, meaning it can withstand significant temperature variations without cracking or warping.Another notable property is the glass's resistance to weather elements. It provides reliable protection against UV rays, helping to minimize fading in interior spaces and maintaining the integrity of furnishings and artworks. Furthermore, the smooth surface of float glass makes it easy to clean and maintain, adding to its practicality in both residential and commercial settings.

Applications in Various Industries

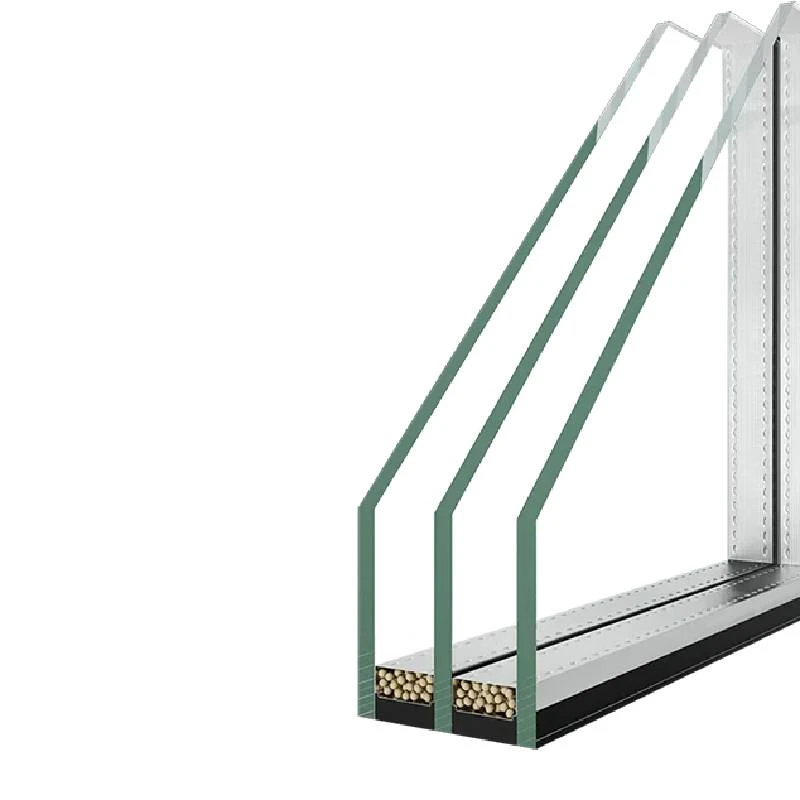

The applications of plain float glass are extensive. In architecture, it is primarily used for windows, doors, and facades, providing both aesthetic appeal and functionality by allowing natural light to penetrate indoor spaces. Its energy efficiency can be enhanced by using low-emissivity (Low-E) coatings, which reflect heat while allowing light to pass through.

In the automotive industry, float glass is critical for the manufacturing of windshields and side windows. Its clarity and strength are vital for safe vehicle operation and driver visibility. Moreover, the glass can be tempered or laminated to increase its strength and safety further.

Beyond construction and automotive use, plain float glass finds applications in various consumer products, from mirrors to glass tabletops. Its versatility also allows for creative uses in art installations, where the clarity and reflective properties create unique visual effects.

Environmental Considerations

With the growing emphasis on sustainability, the production and disposal of glass have come under scrutiny. However, float glass is recyclable, and a significant percentage of glass can be repurposed into new glass products. This aspect makes it an environmentally friendly choice, aligning with global efforts towards reducing waste and conserving natural resources.

Conclusion

In conclusion, plain float glass is more than just a basic building material; it represents a blend of simplicity and sophistication. Its production process, unique properties, and wide range of applications underscore its importance in various industries. As technology advances and sustainability becomes increasingly crucial, the role of plain float glass will continue to evolve, ensuring its place as a fundamental material in our daily lives.