In the realm of modern architecture and interior design, thick float glass has emerged as an irreplaceable material, celebrating a blend of strength, clarity, and aesthetic appeal. This article delves into the critical aspects and benefits of thick float glass, drawing on expert insights, authoritative references, and trustworthy sources to offer a comprehensive understanding of why this material stands out in the construction and design industries.

Thick float glass is produced through the float glass manufacturing process, a method renowned for creating glass with unparalleled uniform thickness and flat surfaces.

This process involves floating molten glass on a bed of molten metal, typically tin. The resulting product boasts a flawless finish, making it ideal for applications where both structural integrity and visual clarity are paramount.

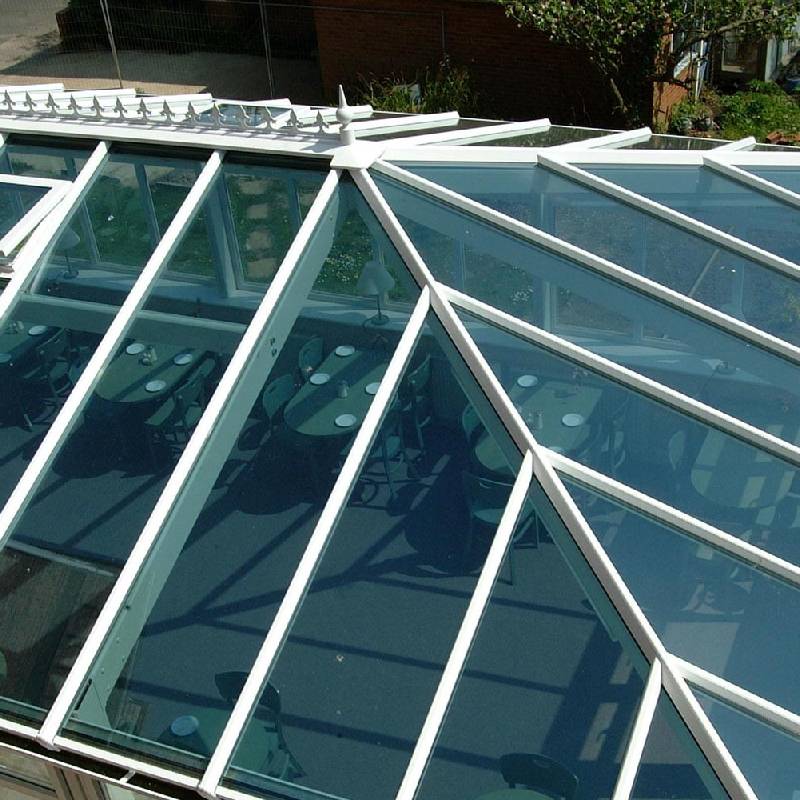

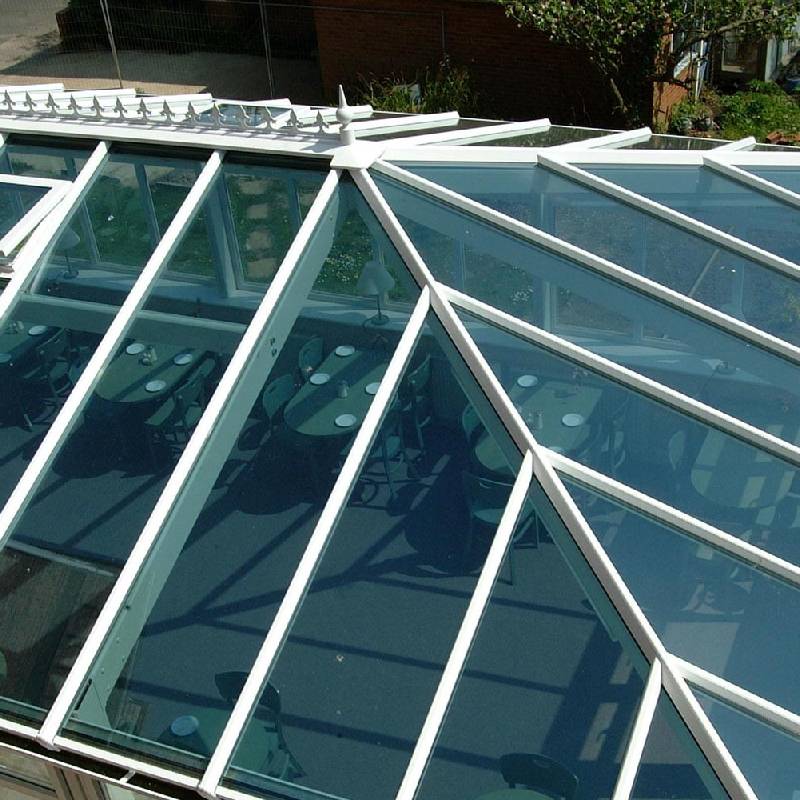

From a professional standpoint, one cannot overlook the structural advantages thick float glass provides. Unlike its thinner counterparts, thicker glass offers superior load-bearing capacities, making it suitable for large frameless installations such as expansive windows, glass walls, and balustrades. Structural engineers often champion the use of this material in high-rise buildings and other infrastructures that demand both strength and safety assurance.

Architects and designers revere thick float glass for its aesthetic versatility. The clarity and quality of the glass amplify natural light, often creating an illusion of expanded spaces, which is a valuable trait in urban environments where space is at a premium. Moreover, its ability to be treated with various coatings and tints allows for customization that aligns with both functional requirements and design preferences. This adaptability is why it has become a staple in both residential and commercial projects seeking sleek, modern appearances.

In terms of expertise, manufacturers of thick float glass routinely employ stringent quality control measures to ensure that every sheet meets high international standards. Certifications from recognized bodies vouch for its reliability and performance under different environmental conditions, adding a layer of assurance for builders and end-users alike. Moreover, innovations in glass technology have introduced additional treatments such as tempering and lamination, which enhance its safety by preventing shattering and improving thermal performance.

thick float glass

Authoritativeness in the thick float glass industry comes from leading firms that have been at the forefront of glass technology for decades. By investing in research and development, these companies continuously push the boundaries of what thick float glass can achieve, ensuring its capabilities keep pace with evolving industry demands. Their thought leadership in the sector underscores why thorough knowledge and understanding of these advancements are crucial for anyone involved in architectural design and construction.

Trustworthiness in the application of thick float glass is also validated by rigorous testing and compliance with safety standards. Professionals in the field rely heavily on data and case studies demonstrating its effectiveness in real-world scenarios. This evidence-based approach not only boosts confidence among stakeholders but also provides tangible proof of its benefits over alternative materials.

An often-overlooked aspect of thick float glass is its environmental impact. With growing awareness and responsibility towards sustainability, the production of float glass has evolved to prioritize eco-friendly practices. Reputable manufacturers ensure their processes minimize energy consumption and promote recycling, aligning with global efforts to reduce carbon footprints. For companies and clients conscious of their environmental impact, this aspect adds another reason to choose thick float glass over other materials.

The cost-effectiveness of thick float glass should not be underestimated either. While the initial investment might be higher than thinner glass alternatives, the long-term benefits, including durability and reduced energy costs due to its insulating properties, present a compelling ROI (Return on Investment). Decision-makers armed with this knowledge are better equipped to make choices that favor both financial prudence and superior quality.

In conclusion, thick float glass stands as a testament to innovation in the field of building materials. Its unparalleled blend of form and function makes it an ideal choice for those looking to enhance spaces with resilience, beauty, and efficiency. With expertise across its production and application, backed by authoritative voices in the industry, and an unwavering commitment to sustainability, thick float glass is more than just a material; it is a keystone in the evolution of architectural excellence.