Low iron float glass has rapidly become an industry favorite for applications needing exceptional clarity and color neutrality. As a seasoned expert in glass manufacturing and application, I can affirm that its unique properties offer distinct advantages for both commercial and residential projects.

One of the prime characteristics of low iron float glass is its ability to transmit light with minimal color distortion. Unlike traditional float glass, which has a green tint caused by iron oxide, low iron glass contains significantly less iron content. This reduction allows for greater transparency and truer color representation—a crucial factor when precision and aesthetic are paramount. With an industry focus on sustainable building practices, low iron glass's ability to maximize natural light ingress supports energy efficiency goals by reducing dependence on artificial lighting.

In architectural applications,

the demand for large, unobtrusive glazed surfaces is rising. Low iron float glass fulfills this demand by providing a clear view that enhances spatial connection with the environment. This is particularly beneficial in settings such as high-end retail spaces or luxury residential properties, where visual appeal and the maximization of views are critical. Furthermore, the glass’s clarity is particularly advantageous for showrooms and museums, where the emphasis on detail and display is crucial.

From a product perspective, manufacturers benefit from its versatility. The glass can be tempered, laminated, or even coated with various finishes for additional functionalities like increased thermal performance or reflective properties. This adaptability means that low iron float glass can meet a wide range of design and performance criteria, making it a preferred choice among architects and builders seeking specialized solutions.

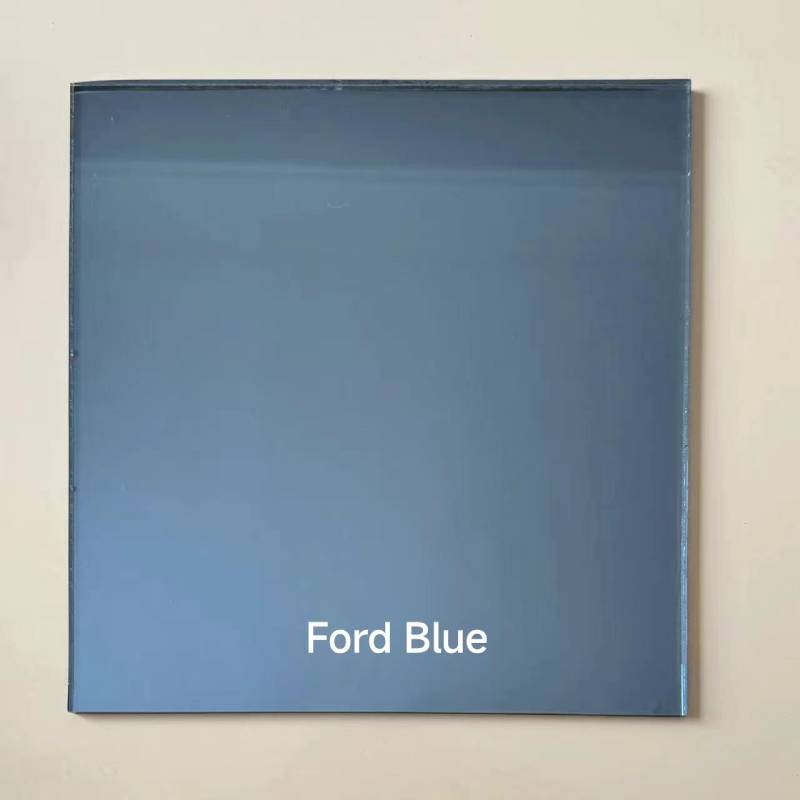

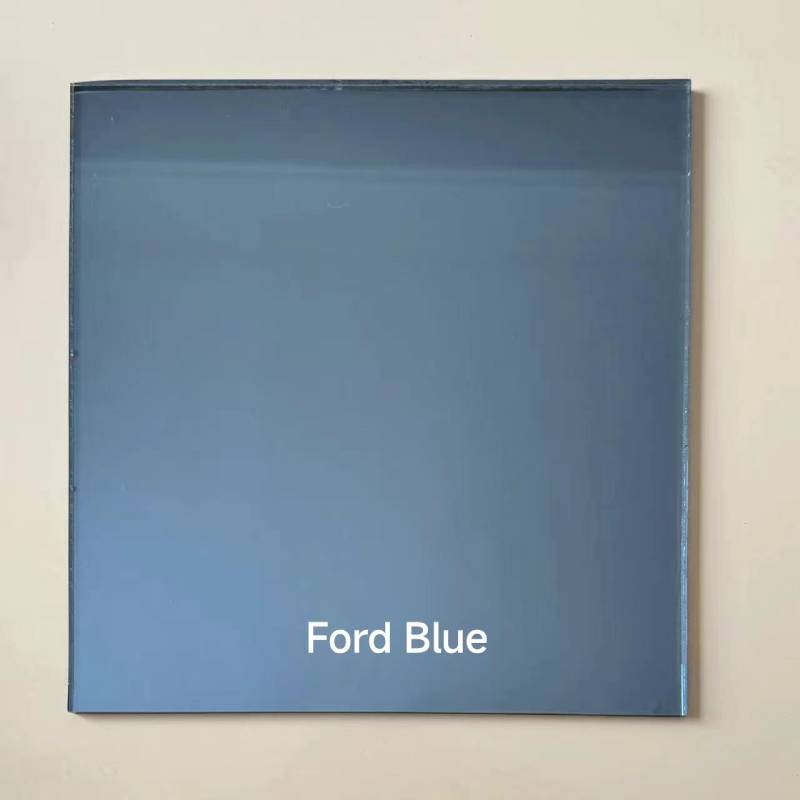

low iron float glass

The production process of low iron float glass is testament to both innovation and precision. The process involves meticulously controlled melting and cooling stages that ensure the highest quality standards. This level of manufacturing expertise not only guarantees product consistency but also reinforces confidence in its use within safety-critical environments such as hurricane zones and high-altitude locations.

In terms of reliability, projects employing low iron float glass often experience enhanced durability and resistance to degradation. Its robust nature ensures longevity, making it a wise investment for projects where lifecycle costs are a consideration. Knowing that the glass maintains its aesthetic and functional integrity over time positions it as a material that embodies both quality and value.

For industries such as solar energy, low iron float glass plays a pivotal role. Its high clarity and light transmittance capabilities significantly increase the efficiency of photovoltaic panels. This relationship underscores the glass's importance in the evolving energy landscape, where maximizing output from renewables is essential.

In conclusion, low iron float glass is not merely a construction material; it’s an integral component that advances both innovation and sustainability. Its unparalleled clarity, adaptability, and performance characteristics make it ideal for forward-thinking projects that prioritize both functionality and design. For industry professionals, specifying low iron float glass is choosing excellence—ensuring projects benefit from a material that epitomizes modern architectural ideals.