The manufacturing of transparent float glass begins with the melting of raw materials in a furnace at temperatures reaching 1,700 degrees Celsius (about 3,092 degrees Fahrenheit). Once the mix reaches a molten state, it is poured onto the tin bath, where it spreads out evenly. As it cools, it solidifies into flat sheets. The thickness of the glass is controlled by adjusting the flow rate of the molten glass and the speed at which it is drawn off the tin. The resulting product is then annealed in a lehr, which helps to relieve internal stresses, ultimately enhancing its durability.

Home

Home Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber

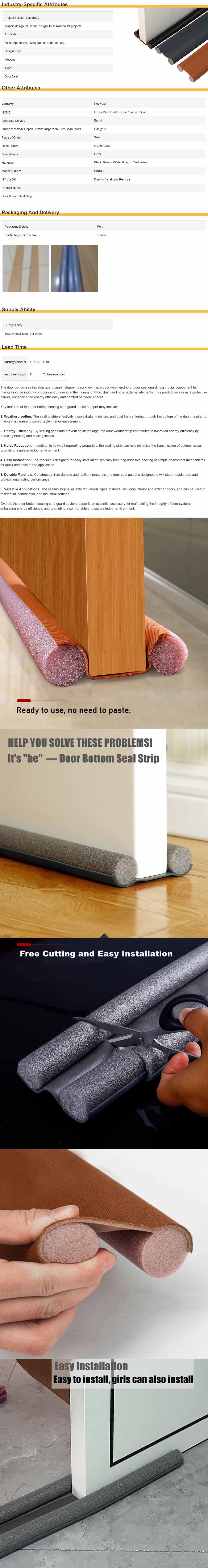

Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills

Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills