tempered glass company

Home

Home- · top glass tinted tempered glass

- · carved louis leaner silver mirror

- · top glass 2mm mirror glass

- · top glass glass manufacturers

- · top glass silver mantle mirror

- · silver leaf round mirror

- · top glass clear and frosted glass

- · silver glam mirror

- · silver traditional mirror

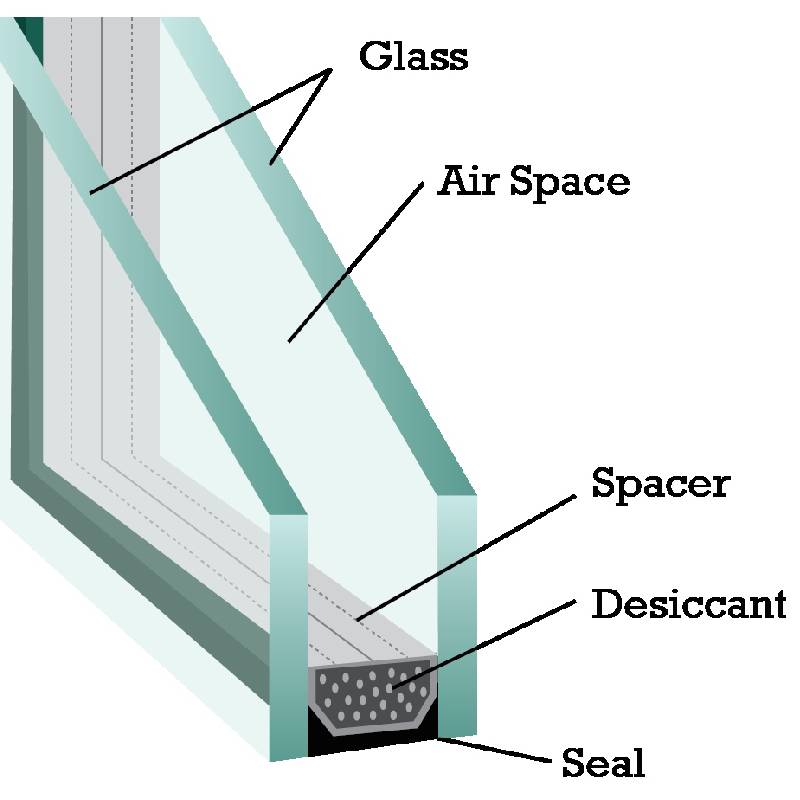

- · low e glass china

Unlike standard window panes, which are typically available in fixed sizes, patterned glass can be cut to fit virtually any shape or size Unlike standard window panes, which are typically available in fixed sizes, patterned glass can be cut to fit virtually any shape or size

Unlike standard window panes, which are typically available in fixed sizes, patterned glass can be cut to fit virtually any shape or size Unlike standard window panes, which are typically available in fixed sizes, patterned glass can be cut to fit virtually any shape or size The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room

The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room The soft, matte finish of frosted glass can serve as a statement piece or complement other design elements within a room

They can feature intricate patterns or motifs that make them stand out as a focal point in any room They can feature intricate patterns or motifs that make them stand out as a focal point in any room

They can feature intricate patterns or motifs that make them stand out as a focal point in any room They can feature intricate patterns or motifs that make them stand out as a focal point in any room It can be easily customized into various shapes and sizes, accommodating diverse design requirements It can be easily customized into various shapes and sizes, accommodating diverse design requirements

It can be easily customized into various shapes and sizes, accommodating diverse design requirements It can be easily customized into various shapes and sizes, accommodating diverse design requirements .

.  Shaft seal dimensions must match the shaft and bearing dimensions to ensure a tight seal Shaft seal dimensions must match the shaft and bearing dimensions to ensure a tight seal

Shaft seal dimensions must match the shaft and bearing dimensions to ensure a tight seal Shaft seal dimensions must match the shaft and bearing dimensions to ensure a tight seal