tempered glass company

Home

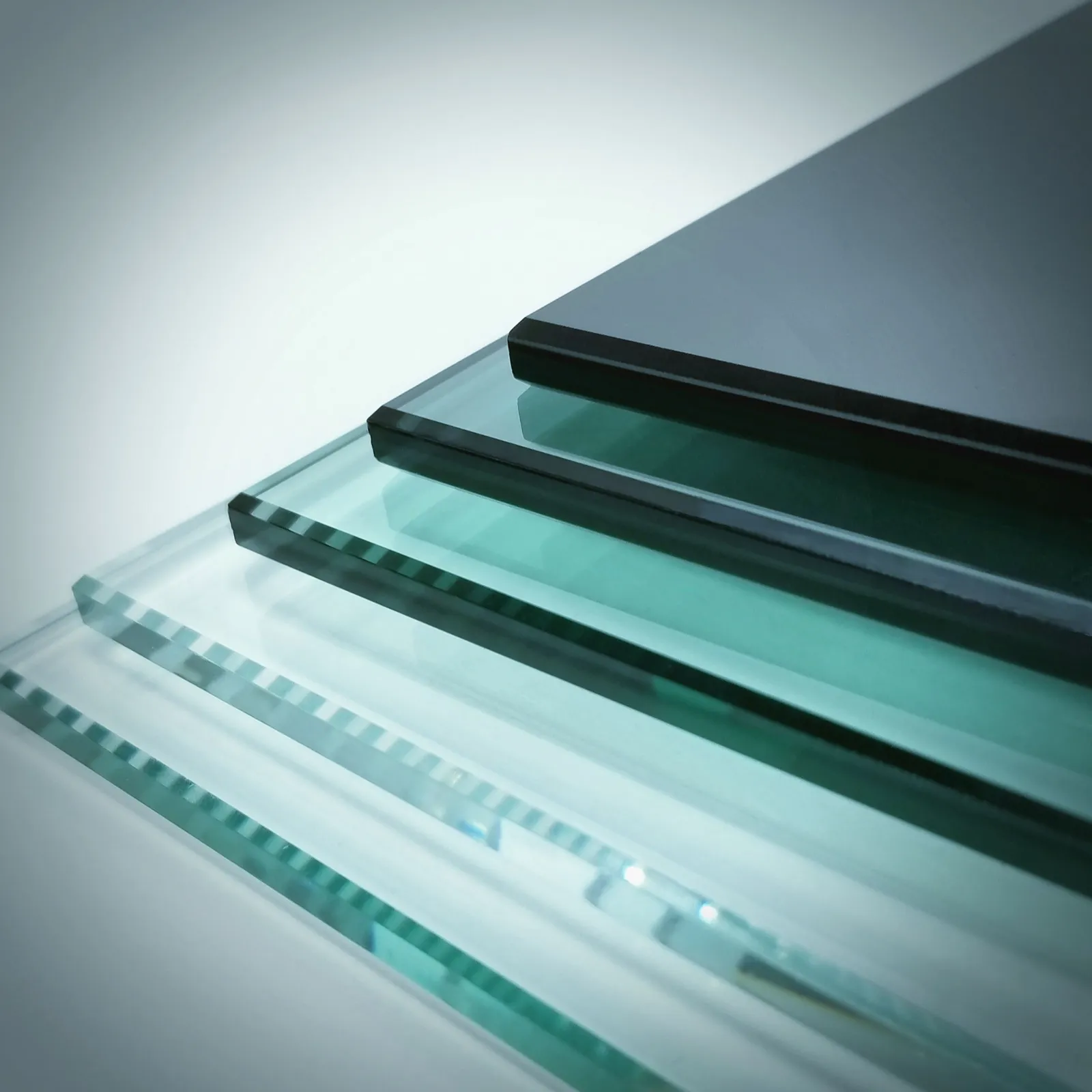

Home- · top glass tinted tempered glass

- · carved louis leaner silver mirror

- · top glass 2mm mirror glass

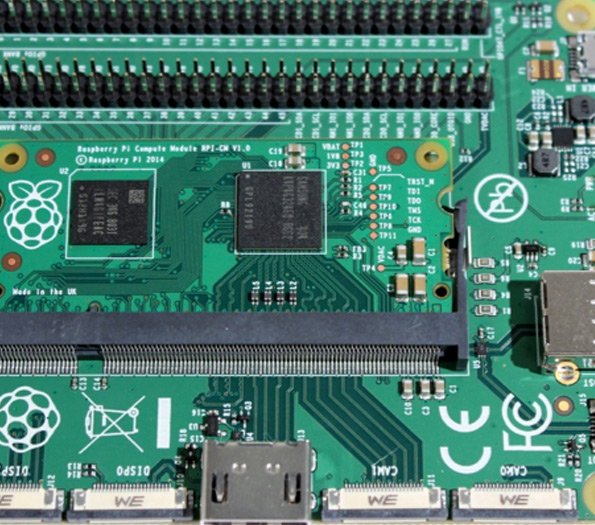

- · top glass glass manufacturers

- · top glass silver mantle mirror

- · silver leaf round mirror

- · top glass clear and frosted glass

- · silver glam mirror

- · silver traditional mirror

- · low e glass china

Its ability to filter out harmful ultraviolet (UV) rays protects interior furnishings from fading and extends their lifespan Its ability to filter out harmful ultraviolet (UV) rays protects interior furnishings from fading and extends their lifespan

Its ability to filter out harmful ultraviolet (UV) rays protects interior furnishings from fading and extends their lifespan Its ability to filter out harmful ultraviolet (UV) rays protects interior furnishings from fading and extends their lifespan