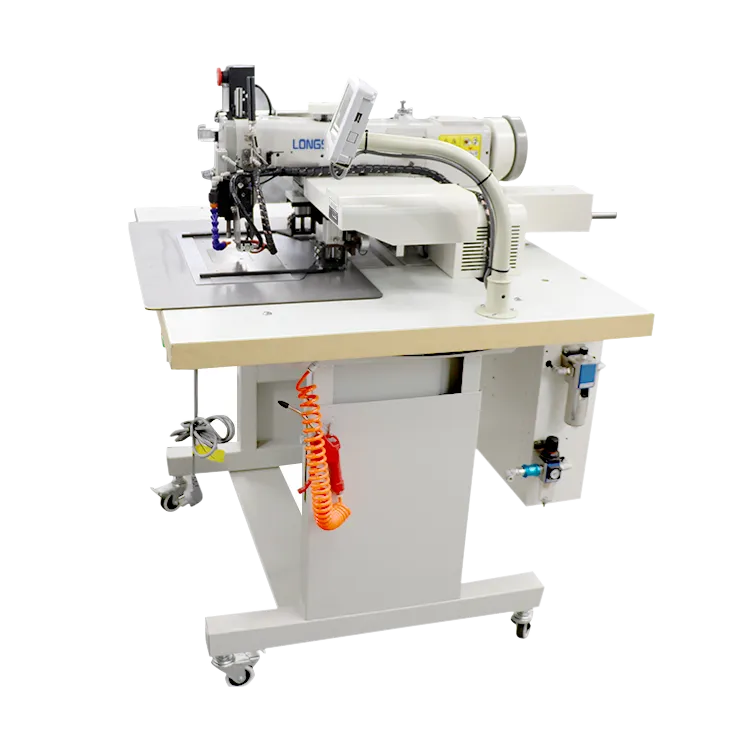

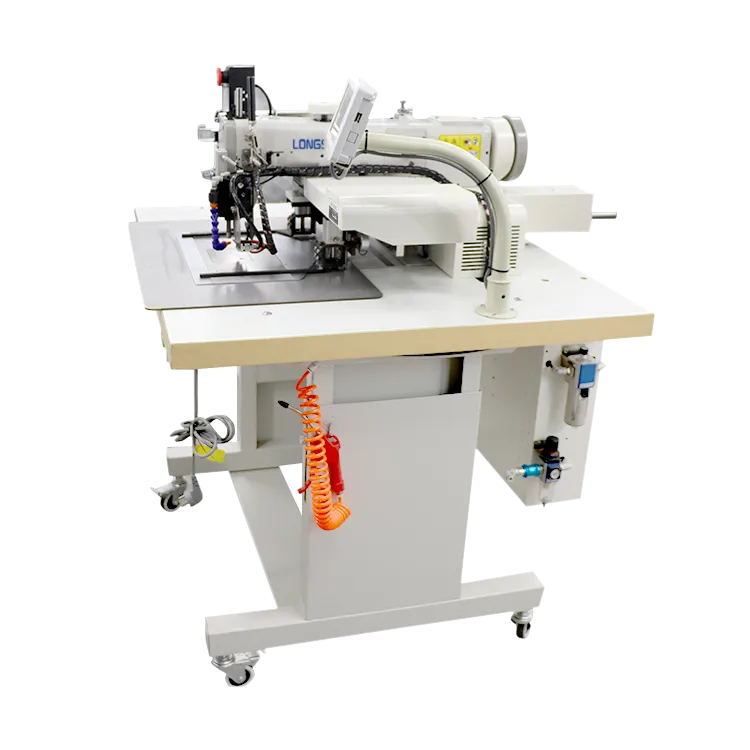

Leather is a material prized for its durability and elegance, commonly used in crafting bags, shoes, belts, and furniture. Chinese hand crank sewing machines excel in leatherwork because of their robust engineering, which enables them to stitch through multiple layers of tough leather without straining the machine. This adaptability makes them a favorite among hobbyists, tailors, and professional leatherworkers alike. The machines can handle various types of stitches, allowing artisans to express their creativity and individual style through their work.

Home

Home This is especially important in situations where drivers need to react quickly, such as during emergency maneuvers or at night This is especially important in situations where drivers need to react quickly, such as during emergency maneuvers or at night

This is especially important in situations where drivers need to react quickly, such as during emergency maneuvers or at night This is especially important in situations where drivers need to react quickly, such as during emergency maneuvers or at night

In finance, Fibonacci retracement levels are used to predict market trends and identify potential support and resistance levels In finance, Fibonacci retracement levels are used to predict market trends and identify potential support and resistance levels

In finance, Fibonacci retracement levels are used to predict market trends and identify potential support and resistance levels In finance, Fibonacci retracement levels are used to predict market trends and identify potential support and resistance levels