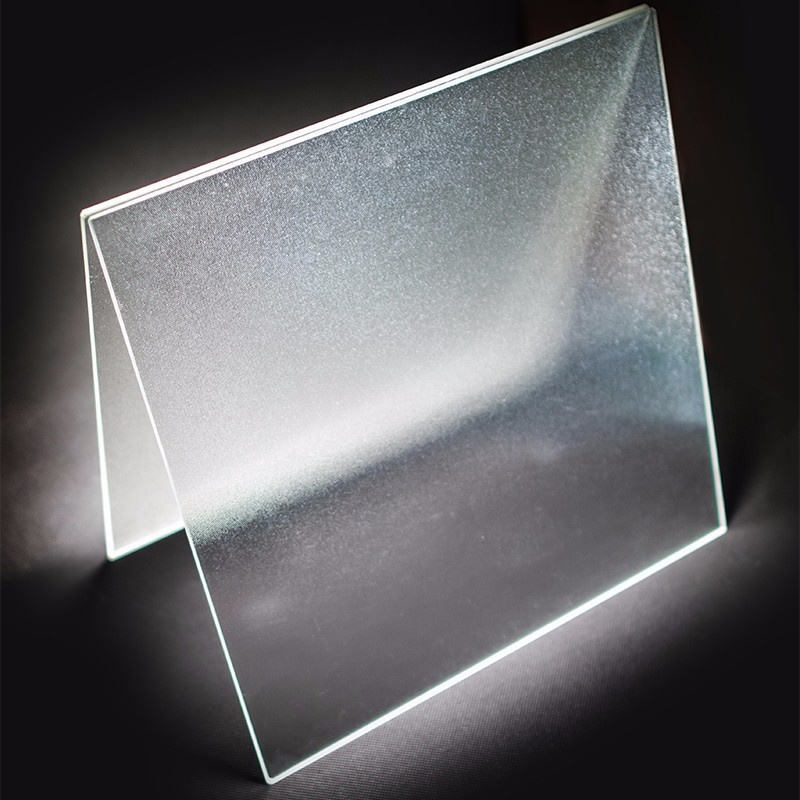

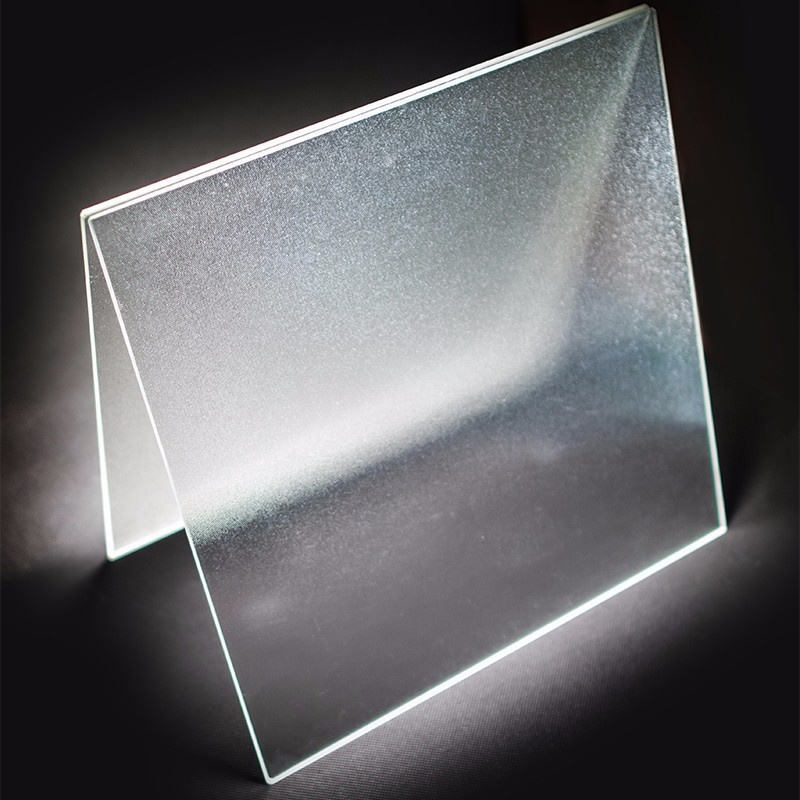

Anti-reflective glass, a crucial innovation in the field of modern optics, has been transforming the way consumers and industries interact with glass surfaces. By minimizing glare and improving visibility, anti-reflective glass enhances user experience across various applications, from consumer electronics to architectural elements. As the demand for enhanced optical clarity and aesthetic quality rises, understanding the significance and application of anti-reflective glass becomes paramount for both consumers and manufacturers.

Applications of anti-reflective glass are vast, spanning numerous industries. In the realm of consumer electronics, this specialty glass is employed in smartphone screens, tablets, and computer monitors. The primary benefit in these applications is the reduction in screen glare under bright lighting, which enhances visibility and reduces eye strain for users. For manufacturers, the incorporation of anti-reflective glass in product design not only aligns with consumer expectations for high-performance devices but also extends the usability of their products in diverse lighting conditions.

Beyond electronics, the architectural industry greatly benefits from anti-reflective glass. Building facades that incorporate expansive glass surfaces often suffer from significant reflectivity, which can be both visually disturbing and detrimental to energy efficiency. Anti-reflective glass mitigates these issues by allowing more light to pass through, thereby improving natural lighting within the structure while reducing the need for artificial lighting. This increase in energy efficiency makes buildings more sustainable, aligning with global trends towards greener architectural practices.

The automotive industry is yet another sector that extensively employs anti-reflective glass, particularly in vehicle dashboards and instrument panels. The reduction of glare is crucial for drivers, ensuring that vital information from these displays is always visible under varying lighting conditions. This contributes to greater driving safety and comfort, underscoring the necessity for high-quality anti-reflective coatings in automotive design.

From a technical perspective, the manufacture of anti-reflective glass involves the precise application of thin-film coatings that reduce surface reflectivity. This is achieved by engineering the refractive index of the coatings to match that of the glass, minimizing the reflection of light waves. Expertise in this domain is essential to ensure the coatings are durable, adhere uniformly to the glass surface, and meet specific optical performance criteria.

anti reflective glass

Manufacturers and consumers alike must trust the source and quality of their anti-reflective glass. Verification from authoritative bodies, compliance with industry standards, and transparent certification processes are vital components in ensuring the reliability of these products. Users must have confidence in the glass’s performance not just upon installation, but throughout its lifecycle.

To build trust and ensure continual customer satisfaction, manufacturers often provide data-backed evidence of their products' performance. This includes tests under various environmental conditions, long-term durability studies, and the demonstration of reduced glare effectiveness. By maintaining transparency and sharing these results openly, manufacturers can solidify consumer confidence in their products.

Ultimately, the evolution and adoption of anti-reflective glass signify a shift towards improved user experience and functional aesthetics. As technology advances and consumer expectations grow, the demand for such specialty glass will continue to expand. For stakeholders in technology, architecture, and automotive industries, staying ahead of trends in anti-reflective glass can provide a competitive edge, ensuring their products not only meet but exceed market expectations.

Leveraging the benefits of anti-reflective glass requires a balance of innovation, quality assurance, and authoritative knowledge. As more industries recognize its value, the call for expertise in crafting and applying these coatings will rise. Stressing the importance of these factors not only positions a brand as a leader in the field but also guarantees that consumers receive the highest level of product performance, confirming their investment in anti-reflective glass as one that enhances both utility and satisfaction.