Slumping float glass has emerged as a vital technique in the glass industry, providing both artistic and functional applications. This niche but essential process involves reshaping flat glass under controlled heat to achieve a desired form, enhancing its aesthetic and practical utility. Understanding the intricacies of slumping float glass can dramatically impact product quality and broaden market appeal.

Historically rooted in ancient glass-making, slumping has modernized to cater to architectural and design innovations. The process begins with sourcing high-quality float glass, renowned for its uniform thickness and clarity obtained through the float line production. The next step is placing the glass on a mold inside a kiln, where it is gradually heated. Precise temperature control is pivotal, as the glass must reach a viscosity that allows it to mold seamlessly without compromising its structural integrity. Professionals recommend an annealing phase post-slumping to relieve internal stresses, reducing the likelihood of breakage.

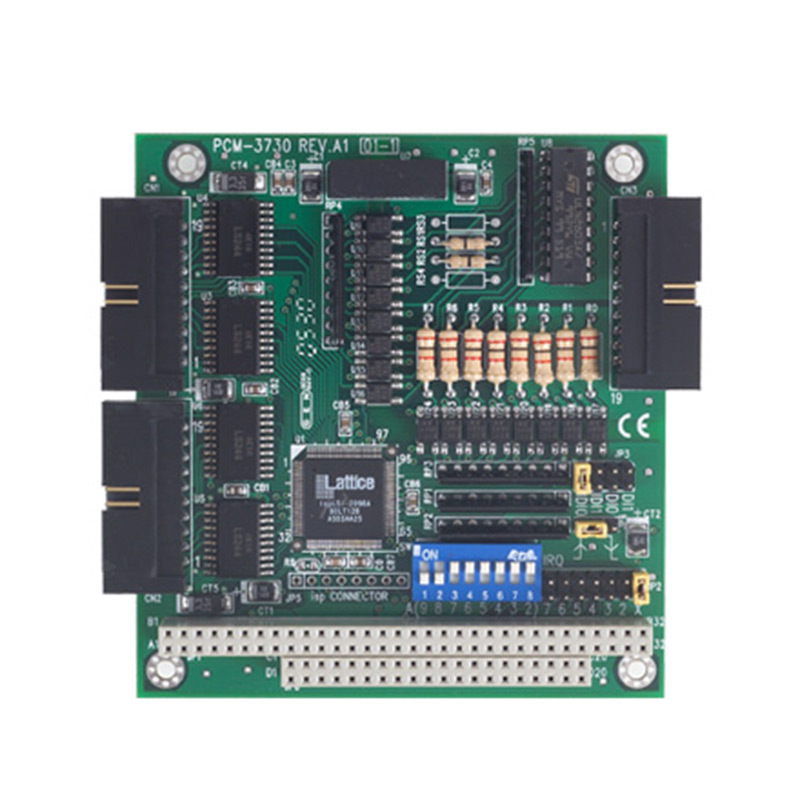

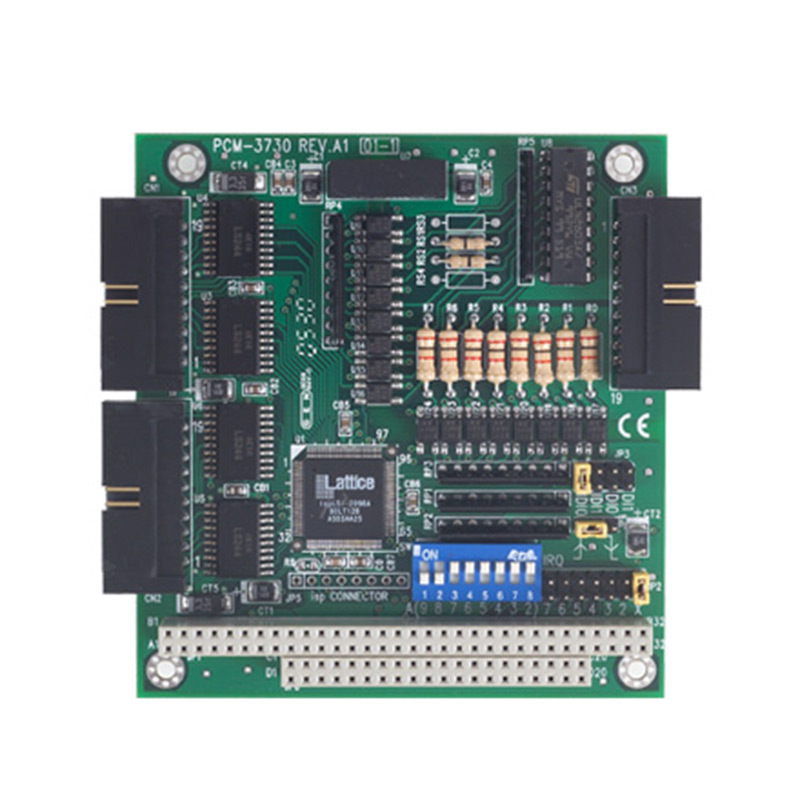

Choosing the right materials and equipment is a reflection of expertise in the field. Kilns hold the heart of this operation, and sophisticated models offer programmable settings essential for intricate designs. The molds, crafted from ceramic or refractory materials, must align with the desired outcome, requiring input from both engineers and artists to marry functionality with creativity. This synergy fosters innovations such as textured architectural panels, bespoke furniture components, and luxurious decorative pieces.

Experience in slumping float glass is invaluable for quality assurance. Trial and error in kiln schedules can be costly; hence, relying on seasoned practitioners enhances confidence in the final product. Anecdotal insights reveal common challenges like thermal shock and devitrification, obstacles that experienced artisans mitigate through adaptive techniques and advanced materials.

slumping float glass

Trustworthiness in glass manufacturing extends to safety certifications and compliance with industry standards. Manufacturers should prioritize adherence to regulations concerning emissions and energy efficiency. Utilizing clean-burning fuels and investing in insulation technology not only safeguard the environment but also affirm a commitment to ethical production.

The market for slumping float glass is rapidly expanding, supported by a growing desire for sustainable and customizable materials. Architects increasingly specify slumped glass for its ability to imbue spaces with natural light while offering significant thermal insulation. In interior design, its functionality extends to versatile tableware and unique art installations, showcasing the material’s adaptability.

Engaging with this transformative process can enhance a product line's appeal. Leveraging expertise in slumping float glass not only redefines conventional glass applications but also elevates the perceived authority and authenticity of a brand. Transparency with clients about the processes and benefits establishes a reliable reputation in a competitive market.

The potential of slumping float glass is boundless when approached with a blend of creativity, scientific acumen, and unwavering dedication to quality. Whether as a cornerstone technique in a manufacturing powerhouse or a specialty craft workshop, this process stands at the forefront of glass innovation, touching numerous facets of contemporary life with elegance and efficiency.