Understanding Pyrolytic Low-E Glass A Comprehensive Overview

In the realm of modern architecture and building design, the choice of materials plays a critical role in both aesthetics and energy efficiency. One such material that has gained significant attention is pyrolytic low-emissivity (Low-E) glass. This specialized type of glass serves as a crucial component in energy-efficient windows, optimizing natural light while minimizing heat transfer.

What is Pyrolytic Low-E Glass?

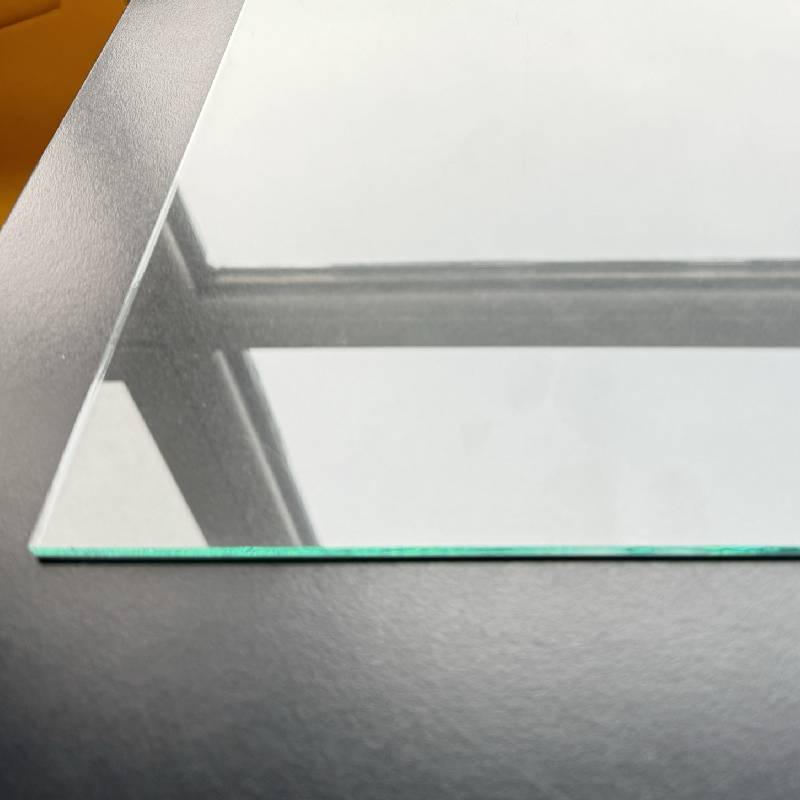

Pyrolytic low-E glass is produced through a high-temperature process where a thin layer of metal oxide is applied to the glass surface. This technique enables the creation of a durable, phosphate-free coating that greatly enhances the glass's thermal performance. The term low-emissivity refers to the glass's ability to reflect infrared radiation while allowing visible light to pass through, which is essential for maintaining comfortable indoor temperatures.

The pyrolytic coating is fixed to the glass during the manufacturing process, making it more robust compared to other types, such as sputtered low-E glass, which has a more delicate coating applied afterward. This durability makes pyrolytic low-E glass suitable for a variety of applications, including commercial buildings, residential homes, and even in the automotive industry.

Benefits of Pyrolytic Low-E Glass

1. Energy Efficiency One of the primary advantages of pyrolytic low-E glass is its superior energy efficiency. By reflecting heat back to its source, whether that be the sun or a heating system, it helps maintain indoor temperatures. This characteristic can significantly reduce the need for artificial heating and cooling, leading to lower energy bills.

2. UV Protection The coating on low-E glass also provides excellent protection against ultraviolet (UV) radiation. This feature is particularly beneficial for protecting interior furnishings, artworks, and flooring from fading and deterioration due to sun exposure.

3. Increased Comfort Pyrolytic low-E glass contributes to increased comfort within a space. By minimizing temperature fluctuations and reducing glare, it helps create a more pleasant indoor environment. This is particularly valuable in commercial spaces where employee productivity can be affected by external conditions.

4. Environmental Impact With growing awareness of climate change and sustainability, the use of energy-efficient materials like pyrolytic low-E glass aligns with modern environmental goals. By reducing energy consumption, buildings equipped with this type of glass can significantly shrink their carbon footprint.

Applications of Pyrolytic Low-E Glass

Pyrolytic low-E glass is versatile and can be used in various architectural applications

- Residential Windows Homeowners are increasingly opting for low-E glass in their window installations to improve energy efficiency and comfort levels in their homes. - Commercial Facades In commercial settings, low-E glass is often utilized in building facades to control heat gain and enhance aesthetic appeal. The reflective properties also contribute to a modern, sleek appearance. - Curtain Walls In multi-story buildings, curtain walls featuring pyrolytic low-E glass provide both thermal insulation and a visually striking exterior. - Skylights The use of low-E glass in skylights allows for optimal daylighting while reducing heat gains, making interior spaces brighter without excessive heat.

Conclusion

Pyrolytic low-E glass represents an innovative solution in the quest for energy efficiency and environmental stewardship in modern architecture. Its unique properties enable architects and builders to create spaces that are not only aesthetically pleasing but also functionally sound. As technology continues to evolve, the integration of materials like pyrolytic low-E glass will play a pivotal role in shaping sustainable building practices for the future. As communities and individuals increasingly prioritize ecological responsibility, pyrolytic low-E glass will undoubtedly remain at the forefront of energy-efficient design trends.

Investing in pyrolytic low-E glass is not just a choice for individual comfort and utility bills; it is a step towards a more sustainable future, fostering an environment where efficiency and beauty go hand-in-hand.