Understanding the Cost Factors of Tempered Glass

Tempered glass, also known as toughened glass, has become increasingly popular in various applications due to its strength, durability, and safety features. This type of glass undergoes a rigorous manufacturing process that enhances its structural integrity and thermal resistance. However, one of the primary considerations for consumers and businesses alike remains the cost of tempered glass. In this article, we will explore various factors that influence the cost of tempered glass and provide a comprehensive understanding of its pricing.

1. Manufacturing Process

The cost of tempered glass is heavily influenced by its manufacturing process. Standard glass is heated to extreme temperatures—usually above 600°C and rapidly cooled. This intense heating and cooling process alters the structure of the glass, making it much stronger than regular glass. The expenses associated with this process, including energy costs, specialized equipment, and quality control measures, contribute significantly to the final price of tempered glass.

2. Raw Material Quality

The quality of the raw materials used in the production of tempered glass plays a critical role in determining the cost. High-quality silica sand, soda ash, and limestone are essential for creating a superior product. Additionally, any additives or treatments required to improve specific properties—such as UV resistance or coloration—will further influence the overall cost. When shopping for tempered glass, it is essential to consider both the quality of the inputs and their subsequent impact on pricing.

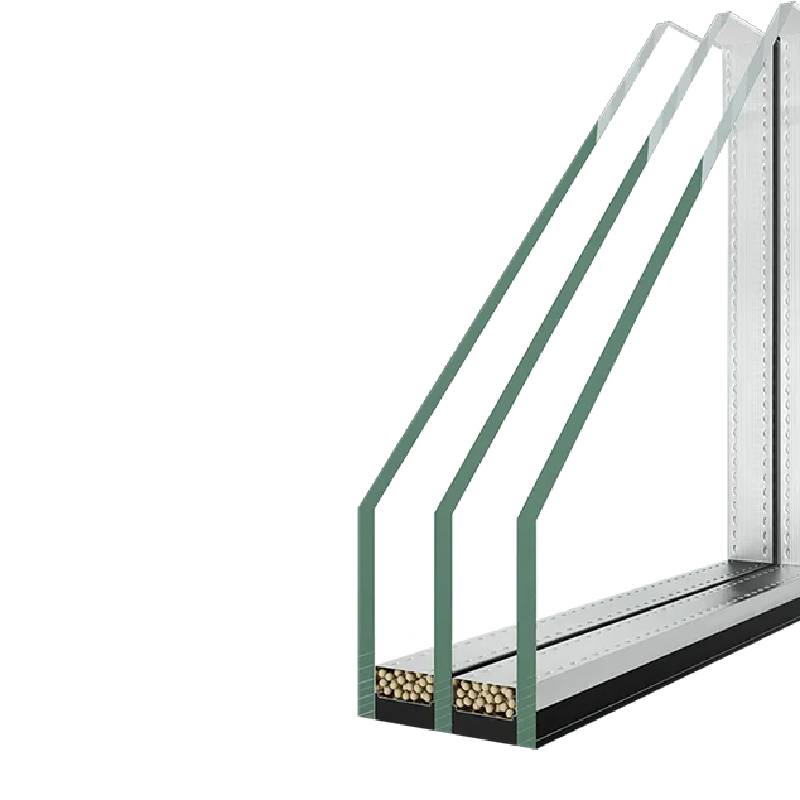

3. Thickness and Size

Another considerable factor affecting the cost of tempered glass is its thickness and size. Generally, thicker glass is more expensive because it requires more raw materials and takes longer to heat and cool during the manufacturing process. Additionally, larger pieces of glass may incur higher shipping costs or may require specialized handling and installation, which will subsequently raise the overall price.

4

. Customization and Design

Custom-designed tempered glass solutions, which cater to specific user specifications, can be costlier than standard sizes and designs. This customization might include intricate cuts, unique shapes, or specific finishing treatments. The engraving, etching, or frosted finishes that some consumers opt for can also drive up costs. Custom orders often have longer lead times and may require additional labor, which can increase the overall expenditure.

5. Market Demand and Availability

The cost of tempered glass can also be influenced by market demand and availability. In times of high demand, perhaps due to a surge in construction or renovation projects, suppliers may raise prices. Conversely, during periods of lower demand, prices may stabilize or decrease. Monitoring market trends and understanding regional demands can provide insights into when to purchase tempered glass at a competitive price.

6. Transportation and Shipping Costs

Transportation and shipping costs can significantly impact the final price of tempered glass. Due to its fragility, tempered glass requires careful packaging and handling to prevent breakage during transit. Depending on the distance between the manufacturer and the buyer, transportation costs can vary. Furthermore, shipping glass internationally may involve tariffs, taxes, and additional fees that contribute to the total expense.

7. Labor and Installation

The cost of tempered glass does not end with the purchase; installation costs are another crucial factor to consider. Employing skilled labor to install and handle tempered glass surfaces—especially in commercial settings or large-scale installations—can add substantially to the total cost. Installer rates can vary greatly, depending on their experience and regional pricing norms. Therefore, when budgeting for tempered glass, it's essential to factor in potential labor costs.

Conclusion

In conclusion, the cost of tempered glass is influenced by a multitude of factors, ranging from its manufacturing and material quality to customization and market dynamics. For homeowners, architects, and builders, understanding these elements is crucial for making informed purchasing decisions. By considering thickness, size, design options, and additional costs such as installation, consumers can better prepare for the investment involved in using tempered glass in their projects. With its myriad benefits, including safety and aesthetic appeal, tempered glass remains a valuable choice, and understanding its costs will ensure that users maximize their value.