Understanding Float Flat Glass A Marvel of Modern Manufacturing

Float flat glass has become a fundamental building block in construction, architecture, and numerous other industries due to its unique properties and manufacturing process. This article delves into the intricacies of float glass, exploring its production, characteristics, applications, and advantages.

What is Float Flat Glass?

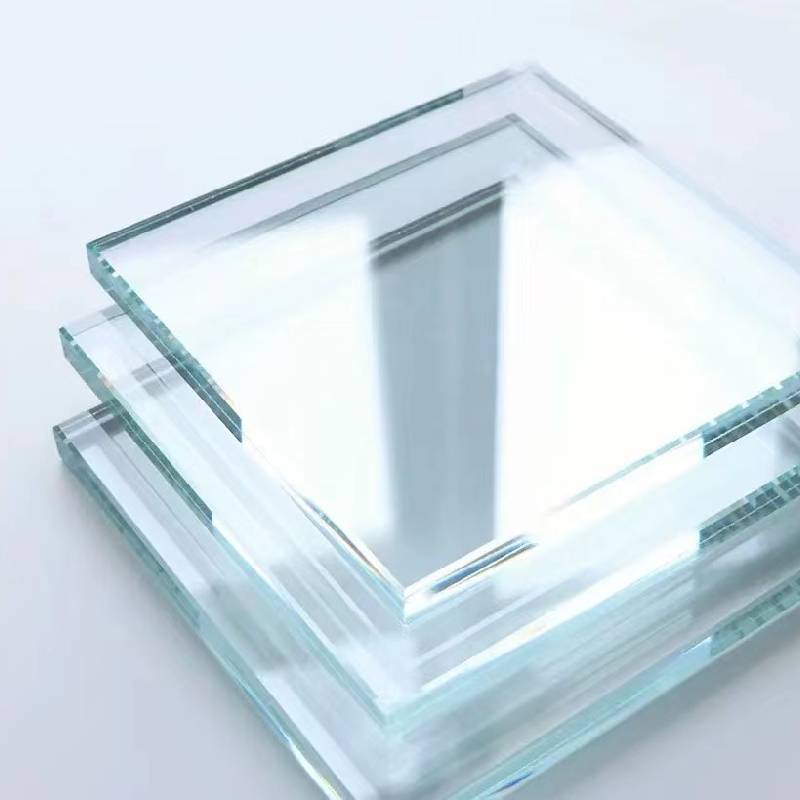

Float flat glass is created using a process developed in the 1950s by Sir Alastair Pilkington, known as the float glass process. This revolutionary technique involves floating molten glass on top of molten tin, allowing the glass to spread out evenly and form a perfectly flat surface. As the glass cools, it retains its flatness and clarity, making it an ideal material for various applications.

The Manufacturing Process

The float glass process begins with the melting of a mixture of silica sand, soda ash, and limestone in a furnace at high temperatures. The molten glass is then poured onto a bath of molten tin, where it spreads out and forms a continuous ribbon. The thickness of the glass is controlled by adjusting the speed at which the glass moves across the tin surface. After a series of cooling and annealing stages, the glass is cut into sheets of desired sizes, and the edges are polished for safety and aesthetics.

Characteristics of Float Flat Glass

One of the standout features of float flat glass is its impressive optical clarity. The process results in glass that is free from bubbles and imperfections, ensuring high transparency. Float glass also boasts uniform thickness, making it easy to install in various applications. Additionally, it has excellent thermal and acoustic insulation properties, which contribute to energy efficiency in buildings.

Applications of Float Flat Glass

The versatility of float glass allows it to be used in a multitude of applications, primarily in the construction industry. It is commonly utilized in windows, doors, storefronts, and curtain walls, enhancing natural light and providing aesthetic appeal. Furthermore, float glass can be treated or coated to enhance its properties, such as increasing its UV resistance or improving energy efficiency.

Beyond construction, float flat glass finds its place in automobiles, electronic devices, and even household items like mirrors and glassware. The automotive industry employs float glass for windshields and side windows, while the electronics sector utilizes it for screens and displays, showcasing its adaptability.

Advantages of Float Flat Glass

The advantages of using float flat glass are numerous. Its high transparency allows for maximum light transmission while minimizing distortion. The uniform thickness provides structural integrity, making it a reliable choice for various applications. Moreover, modern advancements in float glass technology have led to the development of energy-efficient options that reduce heat transfer, contributing to sustainable building practices.

Another significant benefit is its suitability for recycling. Float glass can be melted down and reformed into new glass products, promoting environmental sustainability and reducing waste in landfills.

Conclusion

Float flat glass stands as a testament to innovation in manufacturing, providing a versatile and essential material for contemporary use. Its unique properties, coupled with a robust production process, have made it a cornerstone in various industries. As technology continues to advance, the potential for float glass applications will likely expand, further enhancing its role in creating energy-efficient and aesthetically pleasing environments. The continued development of float glass promises exciting opportunities for architects, builders, and designers, forever transforming the landscapes in which we live and work.