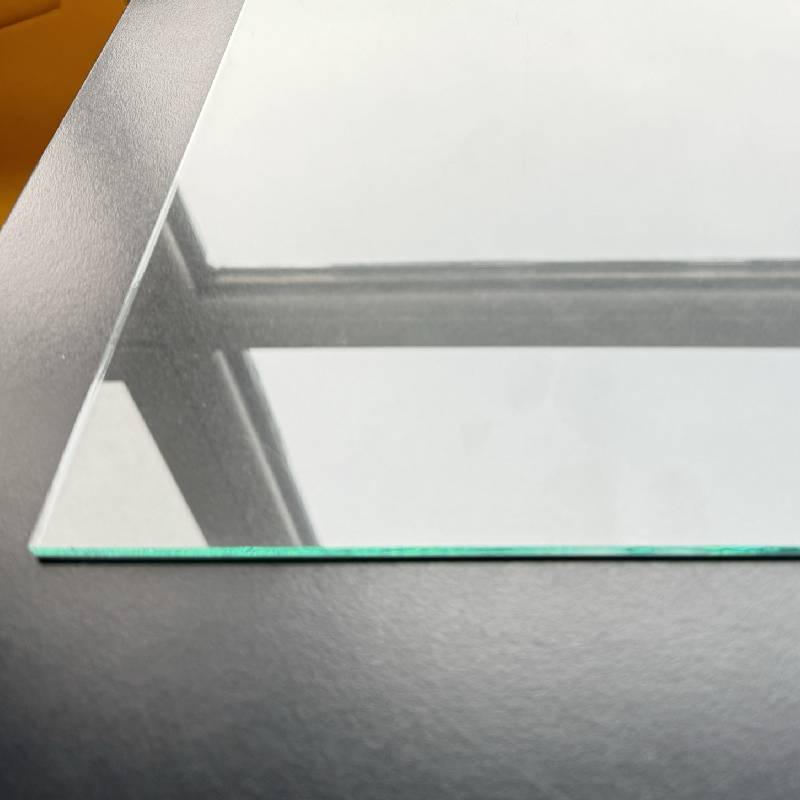

In contemporary architecture, renewable energy, and display technology, the demand for unparalleled transparency and light transmission has surged, positioning ultra clear glass as a cornerstone material. Unlike conventional clear glass, which possesses a greenish tint due to higher iron oxide content, ultra clear variants, often referred to as low iron glass or extra clear float glass, significantly reduce this impurity. This reduction results in superior optical clarity, minimal color distortion, and higher light transmittance, making it indispensable for applications where visual fidelity and energy efficiency are paramount. The industry trend is moving towards larger panel sizes, enhanced structural integrity, and integration with advanced functionalities like low-emissivity coatings, further solidifying the material’s critical role in high-performance building envelopes and sophisticated product designs.

This technological advancement directly addresses the evolving needs of various sectors, including high-end commercial and residential construction, solar photovoltaic (PV) modules, sophisticated display cases, and specialized industrial equipment. The market for products like ultra clear float glass and extra clear float glass is continuously expanding, driven by aesthetic preferences for unhindered views and the functional necessity for maximum light harvesting. Furthermore, specialized applications such as ultra clear shower glass and ultra clear tempered glass exemplify the versatility and robustness required in demanding environments, ensuring both safety and pristine visual appeal. Understanding the intricate manufacturing processes, technical specifications, and diverse application benefits of this material is crucial for architects, engineers, and product developers alike.

The production of low iron ultra clear glass is a meticulous process, primarily utilizing the advanced float glass method but with critical modifications to achieve its exceptional clarity. The journey begins with carefully selected raw materials, where the silica sand, soda ash, dolomite, and limestone are chosen for their extremely low iron oxide (Fe2O3) content, typically below 0.01%. This precise selection is fundamental to minimizing the characteristic green tint seen in standard glass. These materials are then precisely weighed, mixed, and fed into a high-temperature furnace, where they are melted at approximately 1600°C to form a molten glass mass.

The molten glass is then precisely poured onto a bath of molten tin, which is held at a controlled temperature and atmosphere. On this perfectly flat tin surface, the glass floats and spreads out, achieving an exceptionally smooth and parallel surface without requiring mechanical polishing. The thickness of the glass is controlled by the speed at which it is drawn from the tin bath. As the glass ribbon moves along the bath, it gradually cools to approximately 600°C before entering the annealing lehr. In the lehr, the glass is slowly cooled in a controlled manner to relieve internal stresses, preventing cracking or breakage during subsequent processing and use. Finally, the cooled and stress-free glass ribbon is cut into desired sizes. For applications requiring enhanced strength and safety, such as ultra clear tempered glass, the annealed glass undergoes a thermal tempering process, heating it to near its softening point and then rapidly cooling it to create compressive stresses on the surface, significantly increasing its resistance to impact and thermal shock.

Throughout this process, stringent quality control measures are applied, adhering to international standards such as ISO 9001 for quality management systems and ASTM C1036 for standard specification for flat glass. Regular inspections ensure consistent thickness, optical clarity, and minimal defects. The resulting product boasts a lifespan comparable to standard float glass, typically several decades, when properly installed and maintained. While ultra clear glass finds its primary applications in architectural glazing, solar panels, and furniture, its superior clarity also makes it suitable for critical industrial applications requiring high visibility and material purity, such as viewing windows in controlled environments or specialized instrumentation within, for example, high-purity processing in biopharmaceutical or certain chemical sectors, where visual assessment through a truly clear medium is essential.

The superior performance of ultra clear glass is quantified by several critical technical parameters that differentiate it from standard clear float glass. The most significant is its Visible Light Transmittance (VLT), which can reach over 91% for a typical 3.2mm thickness, compared to approximately 86-88% for standard float glass. This higher VLT ensures maximum natural light penetration, reducing the need for artificial lighting and contributing to energy savings in buildings. Another crucial parameter is the Solar Heat Gain Coefficient (SHGC), which indicates the amount of solar radiation that passes through the glass. While ultra clear glass inherently allows more solar energy to pass through, it can be combined with specialized low-emissivity (low-e) coatings to manage solar heat gain effectively, offering a balanced solution for both light and thermal performance.

Furthermore, the color rendition index (CRI) of objects viewed through extra clear float glass is significantly improved due to the minimal color distortion caused by the reduced iron content. This makes it ideal for display applications where true color representation is essential. For applications like solar panels, the high transparency across the solar spectrum directly translates to increased energy efficiency and power output. The table below provides a comparative overview of key parameters:

| Parameter | Standard Clear Float Glass (4mm) | Ultra Clear Float Glass (4mm) | Unit |

|---|---|---|---|

| Visible Light Transmittance (VLT) | ~88% | ~91% | % |

| Solar Heat Gain Coefficient (SHGC) | ~0.85 | ~0.90 | - |

| UV Transmittance | ~70% | ~75% | % |

| Iron Content (Fe2O3) | ~0.08-0.12% | ~0.01% | % |

| Clarity/Color Tone | Slightly Greenish | Crystal Clear | - |

| Haze | <0.5% | <0.2% | % |

The inherent durability of ultra clear glass also extends to its long-term performance. Its reduced iron content not only enhances clarity but also contributes to better resistance against UV degradation and atmospheric corrosion over time, particularly when combined with protective coatings. This makes it an excellent choice for demanding exterior applications where environmental exposure is a factor. These technical superiorities translate directly into tangible benefits, including improved aesthetics, enhanced energy performance, and extended product lifespan across diverse applications.

The versatility of ultra clear glass enables its deployment across a multitude of high-value applications where visual transparency and aesthetic purity are non-negotiable. In modern architecture, it is widely used for expansive facades, skylights, and interior partitions, creating bright, open spaces and allowing maximum natural light penetration while offering true color rendering of the surrounding environment. Its use in high-rise buildings and luxury residences accentuates design aesthetics and contributes to LEED certification goals by improving daylighting and reducing energy consumption.

Beyond architectural envelopes, low iron ultra clear glass is fundamental to the efficiency of solar photovoltaic (PV) modules, where its high light transmittance directly translates to optimized energy conversion. Its application extends to sophisticated display cases for museums, retail environments, and luxury showrooms, providing an unobstructed view of exhibits and products without any greenish tint. Furthermore, for demanding interior uses, ultra clear shower glass ensures a pristine, spa-like aesthetic that resists mineral buildup when treated with appropriate coatings, while ultra clear tempered glass offers enhanced safety and durability for heavy-traffic areas, balustrades, and structural glazing components. Its exceptional clarity is also valued in specialized optical instruments, laboratory equipment, and even some high-purity processing viewports within chemical or food industries where visual monitoring through an unadulterated medium is critical.

Customization options for ultra clear glass are extensive, allowing for precise integration into diverse project requirements. Manufacturers can provide tailored solutions concerning thickness (from 2mm to 19mm or more), specific dimensions, and shapes (rectangular, circular, custom cut-outs). Edge work, including polished, beveled, or mitered edges, enhances both aesthetics and safety. Surface treatments such as anti-reflective (AR) coatings further reduce glare and maximize light transmission, while low-emissivity (low-e) coatings improve thermal insulation. Additionally, options for laminating ultra clear glass with interlayers (e.g., PVB or SGP) create laminated security glass, offering enhanced sound insulation and protection against impact or forced entry, vital for high-security environments or areas prone to severe weather.

Selecting the right manufacturer for ultra clear glass is paramount to project success, ensuring consistent quality, reliable delivery, and comprehensive support. When evaluating suppliers, key factors include their adherence to international quality standards such as ISO 9001:2015, which verifies robust quality management systems throughout the production cycle. Certifications like ASTM (American Society for Testing and Materials) and EN (European Standards) for specific glass performance criteria (e.g., impact resistance, optical properties) provide objective benchmarks of product quality. Reputable manufacturers will also have a proven track record, often demonstrated by years of service in the industry, significant production capacity, and a portfolio of successful projects and satisfied clients.

Beyond certifications, consider the manufacturer's ability to provide customized solutions, from specific dimensions and thicknesses of ultra clear float glass to complex fabrication requirements like drilling, cut-outs, and edge work. Their technical support capabilities, including advice on glass specifications for different applications and structural considerations, are invaluable. Transparency in testing data, including detailed reports on visible light transmittance, solar performance, and mechanical strength, further builds trust. A manufacturer's partnership with leading architectural firms or solar panel integrators can also be an indicator of their industry standing and product reliability.

For instance, a client feedback from a large-scale architectural project noted, "The supplier's commitment to quality control and their ability to deliver large panels of ultra clear tempered glass on schedule was critical to our project's success. The optical clarity exceeded our expectations, contributing significantly to the building's aesthetic appeal and natural light strategy." This kind of direct experience underscores the importance of a vendor's reliability and product integrity. We pride ourselves on stringent quality control, demonstrated by our consistent adherence to international standards and a dedicated team ensuring every sheet of glass meets precise specifications before shipment.

Q: What makes ultra clear glass different from regular glass?

A: Ultra clear glass, also known as low iron glass, contains significantly less iron oxide (typically 0.01% vs. 0.08-0.12% in standard glass). This reduction eliminates the greenish tint, resulting in superior light transmittance (over 91% VLT) and exceptional optical clarity for true color rendition.

Q: Can ultra clear glass be tempered or laminated?

A: Yes, absolutely. Ultra clear glass can be thermally tempered to produce ultra clear tempered glass, significantly increasing its strength and safety. It can also be laminated with interlayers (PVB or SGP) to create high-performance security glass, offering enhanced sound insulation and protection against impact.

Q: What is the typical lead time for custom ultra clear glass orders?

A: Lead times vary based on the complexity, volume, and specific customization requirements. For standard sizes and thicknesses, it might be 2-3 weeks. For highly customized or large-volume orders, it can range from 4-8 weeks. We recommend contacting our sales team with your project specifications for an accurate estimate.

We understand the critical importance of timely delivery for B2B projects. Our logistics team works diligently to ensure efficient and secure transportation of your ultra clear glass products, whether domestically or internationally. Each shipment is carefully packaged to prevent damage during transit, adhering to industry best practices for glass handling and crating. We provide detailed delivery schedules and tracking information, keeping clients informed every step of the way from factory to site. Our standard delivery cycle aims for optimal balance between speed and cost-effectiveness, tailored to project timelines.

Our commitment to quality extends beyond manufacturing. All our products, including ultra clear float glass and extra clear float glass, are backed by a comprehensive warranty that covers manufacturing defects and performance parameters, typically ranging from 5 to 10 years depending on the product type and application. Our dedicated customer support team is readily available to address any inquiries or concerns, providing expert technical assistance and after-sales service to ensure your complete satisfaction. We believe in building long-term partnerships based on trust, reliability, and unparalleled product quality.