Float Glass Cut to Size Precision and Versatility in Modern Architecture

In the world of modern architecture and design, the significance of float glass cannot be overstated. As a fundamental material, float glass is appreciated for its clarity, smooth surface, and uniform thickness. However, its real potential shines when it is cut to size, allowing for a myriad of applications in both residential and commercial projects. This article explores the process and benefits of float glass cut to size, highlighting its importance in contemporary design.

Float glass is manufactured through a process that involves melting raw materials, primarily silica sand, soda ash, and limestone, at high temperatures. The resultant molten glass is floated on molten tin, creating a perfectly flat surface. This method results in high-quality glass that is free from distortions, making it ideal for applications where transparency and aesthetics are paramount.

One of the most significant advantages of float glass is its versatility. When cut to size, it can be tailored to meet specific design requirements. Whether for windows, facades, glass doors, or interior partitions, custom-sized float glass offers designers the flexibility they need to bring their visions to life. The ability to specify dimensions ensures that the glass fits perfectly within design frameworks, providing seamless integration and an elegant finish.

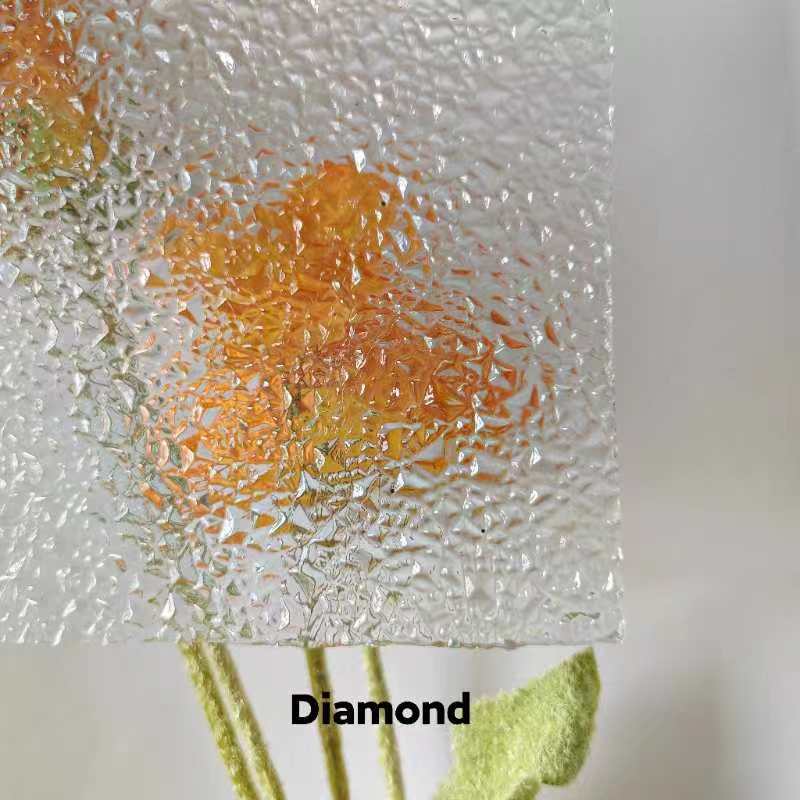

The cutting process for float glass is both precise and sophisticated. Advanced machinery and technology are utilized to achieve accurate cuts with minimal waste. Waterjet cutting, CNC (Computer Numerical Control) machines, and diamond-tipped saws are commonly employed to produce clean edges and intricate shapes. This precision not only enhances the visual appeal of glass installations but also adheres to the strict safety standards required in construction.

Moreover, float glass can be subjected to various treatments after being cut to size. Tempering, laminating, and coating are common processes that enhance the glass's functionality and aesthetics. Tempered glass, for instance, undergoes a thermal treatment that increases its strength and safety. Laminated glass combines layers of glass with an interlayer, providing additional security and sound insulation. Coatings can be applied to improve energy efficiency, such as low-emissivity (Low-E) coatings that reflect heat while allowing natural light to pass through.

In addition to its aesthetic and functional benefits, float glass cut to size contributes to sustainability in architecture. With growing awareness of environmental issues, many architects and builders are opting for materials that reduce energy consumption. High-performance float glass can significantly improve the energy efficiency of buildings, reducing reliance on heating and cooling systems. This not only lowers utility bills but also minimizes the overall carbon footprint of a structure.

In conclusion, float glass cut to size plays a crucial role in modern architecture. Its precision, versatility, and potential for customization make it a go-to material for designers and builders alike. As technology advances, the possibilities for float glass continue to expand, setting new trends in architectural design. Whether enhancing the aesthetics of a space or contributing to energy efficiency, the value of cut-to-size float glass is undeniable, making it an essential element in the construction and design landscape.