Cutting Float Glass to Size A Comprehensive Guide

Float glass, known for its clarity and high optical quality, is a significant material in construction, architecture, and various industrial applications. Unlike other types of glass, float glass is manufactured through a process that involves floating molten glass on top of molten tin, resulting in a flat and even surface. However, one of the most critical aspects of working with float glass is cutting it to the desired size. This article will explore the methods, tools, and considerations involved in cutting float glass to size effectively.

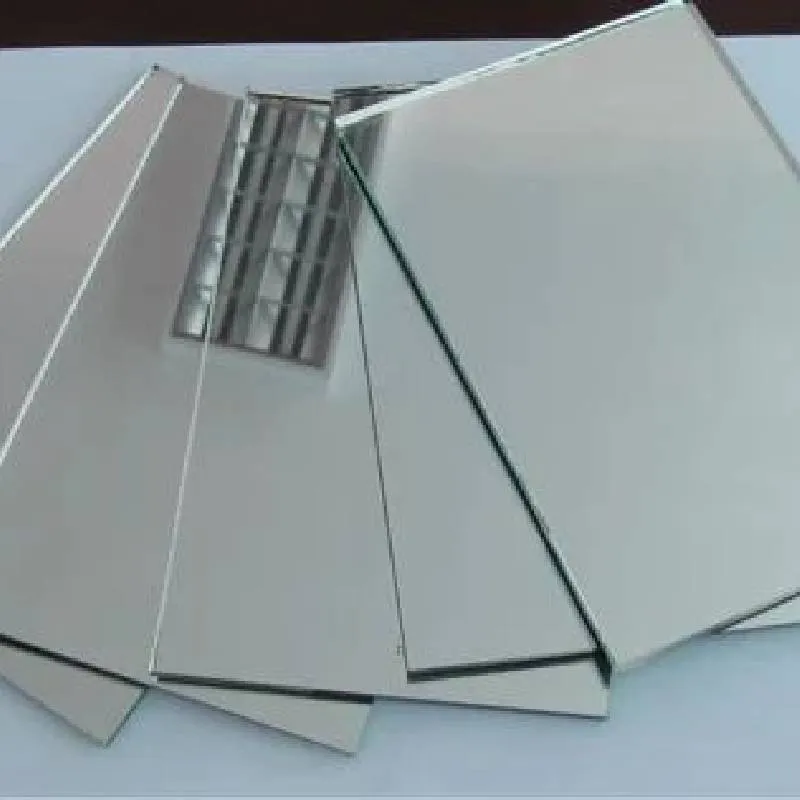

Understanding Float Glass

Float glass is unrestricted by thickness irregularities and is directly correlated to its production method. Its smooth surface and uniform thickness allow it to be cut into various sizes without compromising its integrity. This makes it a preferred choice for windows, glass doors, partitions, mirrors, and more.

Tools for Cutting Float Glass

Cutting float glass requires specific tools to ensure precision and safety. The essential tools include

1. Glass Cutter A handheld glass cutter, typically equipped with a carbide or diamond cutting wheel, is used to score the glass surface. A clean score line is crucial for a clean break.

2. Straightedge Ruler This tool assists in ensuring straight, even lines when scoring the glass. It prevents the cutter from slipping and ensures accuracy.

3. Cutting Mat A specialized cutting mat provides a protective surface under the glass. It helps reduce the risk of breakage and protects the working surface.

4. Safety Gear Protective eyewear and gloves are essential when cutting glass to prevent injuries from sharp edges.

The Cutting Process

Cutting float glass requires careful planning and execution. Here is a step-by-step guide

1. Measure and Mark Begin by measuring the required dimensions of the glass. Use a pencil or a marker to lightly mark the dimensions on the glass. Ensure that the marks are accurate to avoid any waste.

2. Position the Straightedge Place the straightedge along the marked line, ensuring it is stable. This step is vital for achieving a straight score line.

3. Score the Glass Using the glass cutter, apply firm, even pressure while sliding the cutter along the straightedge. The aim is to create a continuous score line across the glass surface. This line should not be too deep but should adequately penetrate the glass.

4. Snap the Glass After scoring, position the scored line over the edge of the cutting mat or a firm surface. With a swift motion, apply downward pressure to snap the glass along the score line. If executed correctly, the glass should break cleanly.

5. Finishing Edges Once the glass is cut, it’s essential to smooth the edges using a glass grinding tool or sandpaper. This step prevents injuries from sharp edges and improves the overall finish of the glass.

Safety Considerations

When cutting float glass, safety should always be a priority. Here are some important safety tips

- Always wear protective eyewear to shield your eyes from glass shards. - Use gloves to protect your hands from sharp edges, but ensure they do not compromise your grip on the tools. - Work in a well-lit area to ensure accurate measurements and cuts. - Be mindful of your surroundings; ensure that no one is in close proximity while cutting glass.

Conclusion

Cutting float glass to size may seem daunting, but with the right tools, techniques, and attention to safety, it can be a straightforward and rewarding process. Whether you’re a professional glazier or a DIY enthusiast, understanding how to effectively cut float glass will enhance your ability to create custom solutions suited for various projects. Remember to take your time and practice your skills to achieve the best results. With experience, you will find that cutting float glass becomes a reliable and efficient skill in your repertoire.