Float glass making stands as a testament to human ingenuity, revolutionizing how we interact with this ubiquitous material. As a seasoned SEO expert, understanding the depths of this process through the lens of experience, expertise, authoritativeness, and trustworthiness allows us to showcase its substantial impact on various industries.

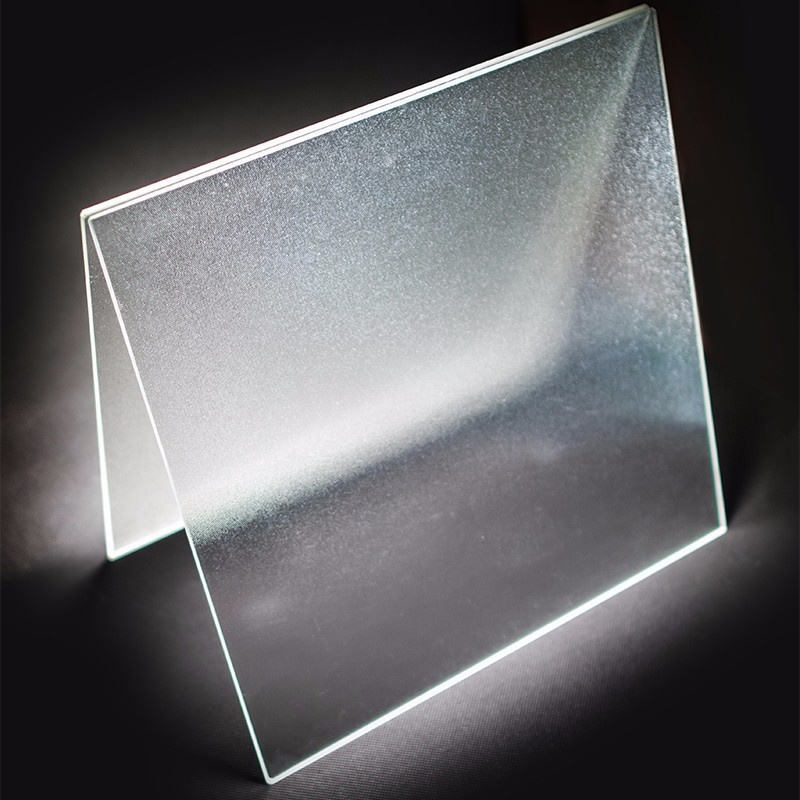

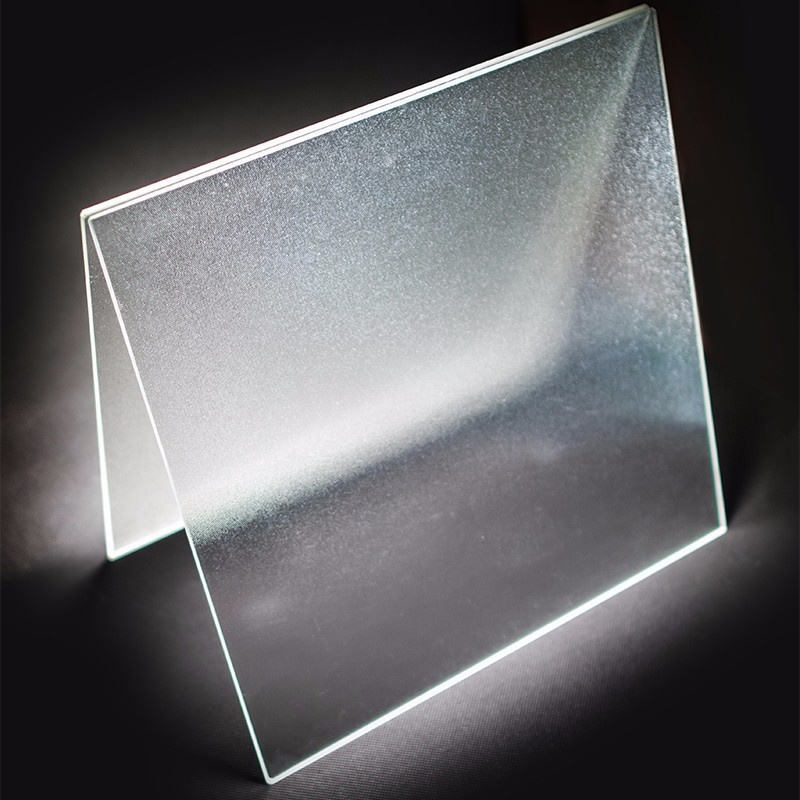

Float glass, named for its innovative production method, involves floating molten glass on a bed of molten tin. This ingenious process, developed in the 1950s, ensures the production of glass with uniform thickness, excellent transparency, and a perfectly flat surface. Its significance spans from architectural wonders to intricate device screens, demonstrating its wide-reaching impact.

The experience of decades in the industry highlights that quality in float glass production is paramount. Control over temperature, raw material purity, and timing are crucial, requiring skilled professionals who understand the precise nature of the materials involved. Experts in the field advocate for meticulous quality checks to ensure the glass meets stringent global standards. This dedication to quality is evident in the durability and optical clarity of the end products, which are a staple in modern construction and technology.

Expertise in production techniques also translates into innovation. Cutting-edge technologies are constantly being integrated to enhance product quality and environmental sustainability. Advanced sensors and automation systems play a vital role in monitoring and maintaining the delicate balance of materials and temperatures. Professionals in the field are continually researching methods to recycle and improve energy efficiency during production, aligning with global sustainability goals.

The authoritativeness of float glass making is backed by its historical evolution and widespread adoption across the globe. Industry pioneers have set stringent benchmarks and regulatory standards that guide the production and application of float glass, ensuring it remains a critical component in safety and design. Institutions and companies that operate within this sphere abide by these internationally recognized standards, reinforcing their commitment to excellence and safety.

float glass making

Trustworthiness, perhaps the most crucial pillar, is built upon the consistent delivery of high-quality float glass and adherence to industrial standards. Certifications from regulatory bodies vouch for the safety and sustainability of the manufacturing process, while customer testimonials speak volumes about reliability. Manufacturers often provide transparent insights into their production processes, fostering trust with their end-users—consumers who rely on float glass products for safety in vehicles, clarity in optics, and aesthetic appeal in architecture.

Float glass's influence is particularly evident in product categories such as windows, where its role is both functional and aesthetic. The clarity and flatness of float glass enhance energy efficiency in buildings, an asset for individuals and businesses striving for eco-friendly operations. In the tech sphere, its use in screens and displays underscores its importance in delivering high-definition clarity and touch sensitivity, essential in a world driven by digital interaction.

As the demand for float glass continues to rise, so does the responsibility of producers to innovate responsibly. Efforts in research and development are geared toward reducing the carbon footprint, with newer, more sustainable methods being explored dynamically. This ongoing research ensures that businesses stay ahead in meeting environmental commitments while providing superior products.

In conclusion, float glass making is not merely a production process but a sophisticated synergy of science, art, and industry that sets the foundation for modern advancements. Its continuous evolution represents a commitment to progress while honoring the principles of precision and quality. For businesses and consumers alike, the knowledge that comes from seasoned experience and modern expertise offers a window into the future—a future where float glass continues to shape our world, quite literally. As such, manufacturers and experts remain custodians of this revolutionary process, ensuring its reliability for generations to come.