The Float Glass Manufacturing Industry An Overview

Float glass is a fundamental material in modern construction and architecture, known for its clarity and versatility. Its manufacturing process involves the floating of molten glass on a bed of molten tin, resulting in a sheet of glass that is smooth and uniform in thickness. This innovative process was developed in the mid-20th century and has since revolutionized the glass industry, making high-quality glass more accessible for various applications. Today, numerous manufacturers specialize in float glass production, contributing significantly to both residential and commercial building projects worldwide.

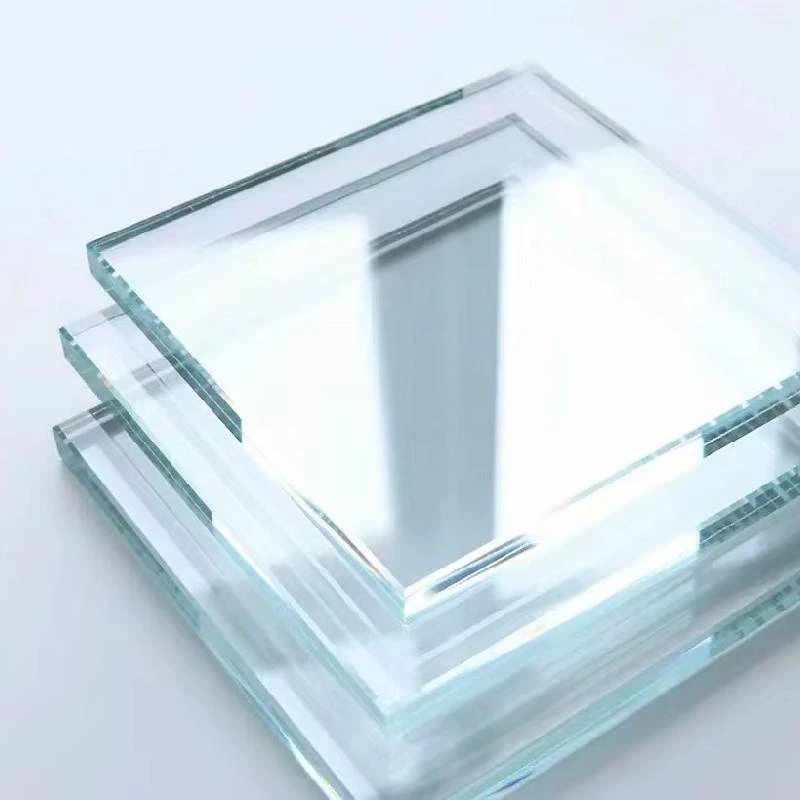

The float glass manufacturing process begins with raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully measured and mixed before being heated to extreme temperatures in a furnace. The molten glass is then poured onto a surface of molten tin, where it spreads out to form a flat, even sheet. This technique not only results in glass that is free of bubbles and imperfections but also allows for varying thicknesses, catering to different specifications required by clients.

Major manufacturers of float glass often invest in advanced technology and automated processes to enhance efficiency and quality control. This includes state-of-the-art furnaces, cutting-edge cooling systems, and automated cutting technology, ensuring that the final product meets stringent industry standards. Leading companies in this sector are geographically diverse, with operations in regions known for both glass production and construction, such as Europe, North America, and Asia.

Among the prominent float glass manufacturers are players like Saint-Gobain, Guardian Industries, and Pilkington. These companies not only focus on producing high-quality float glass but also engage in research and development to create advanced glass solutions such as energy-efficient and self-cleaning varieties. The demand for innovative glass solutions has increased in recent years due to growing trends in sustainability and energy efficiency in building design.

The primary applications of float glass are in the construction of windows, doors, and facades. Its transparency allows for natural light to enter buildings, significantly reducing the need for artificial lighting and contributing to energy savings. Float glass is also crucial in the automotive industry, where it is used for windshields and windows, providing not only visibility but also safety.

In addition to construction and automotive applications, float glass is widely used in interior design, signage, and various furniture designs. The aesthetic appeal of float glass, combined with its functionality, makes it a popular choice among architects and designers.

Sustainability is becoming an increasingly important focus for float glass manufacturers. Many companies are adopting practices to reduce energy consumption and minimize waste during production. The use of recycled glass in the melting process not only lowers energy costs but also contributes to environmental conservation efforts. Moreover, advancements in technology are enabling manufacturers to produce low-emissivity glass, which helps in reflecting heat and reducing greenhouse gas emissions, aligning with global efforts to combat climate change.

Finally, the future of the float glass manufacturing industry appears promising, with continuous innovations and a growing emphasis on sustainability. As urbanization expands and the demand for high-performance building materials increases, float glass manufacturers are likely to play a critical role in shaping the future of architecture and design. The balance between quality, innovation, and environmental responsibility will be key to thriving in this dynamic industry.

In conclusion, the float glass manufacturing sector is at the forefront of providing essential materials that enhance the safety, comfort, and aesthetics of modern structures. With ongoing advancements and a commitment to sustainability, this industry will undoubtedly continue to evolve, meeting the needs of a changing world.