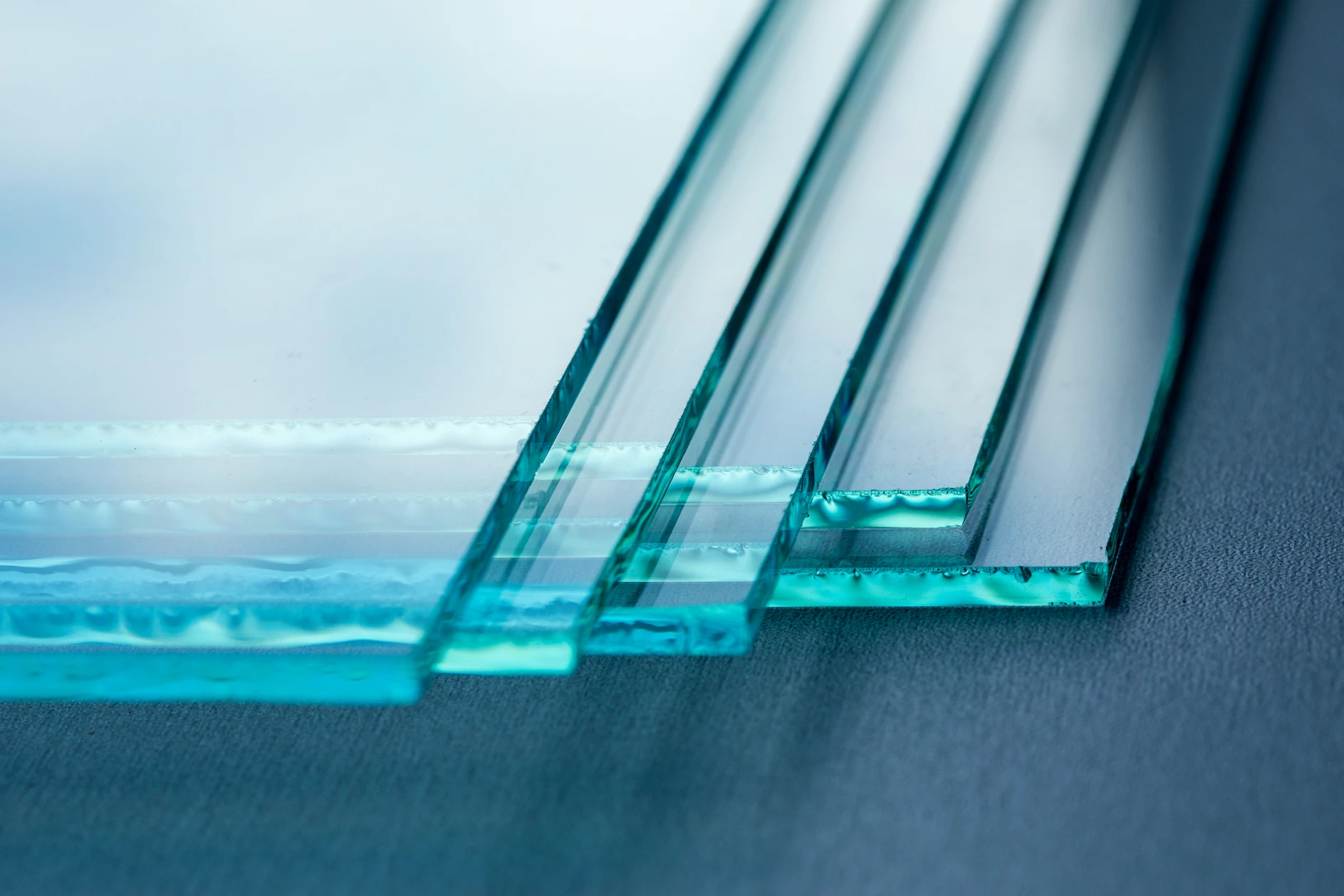

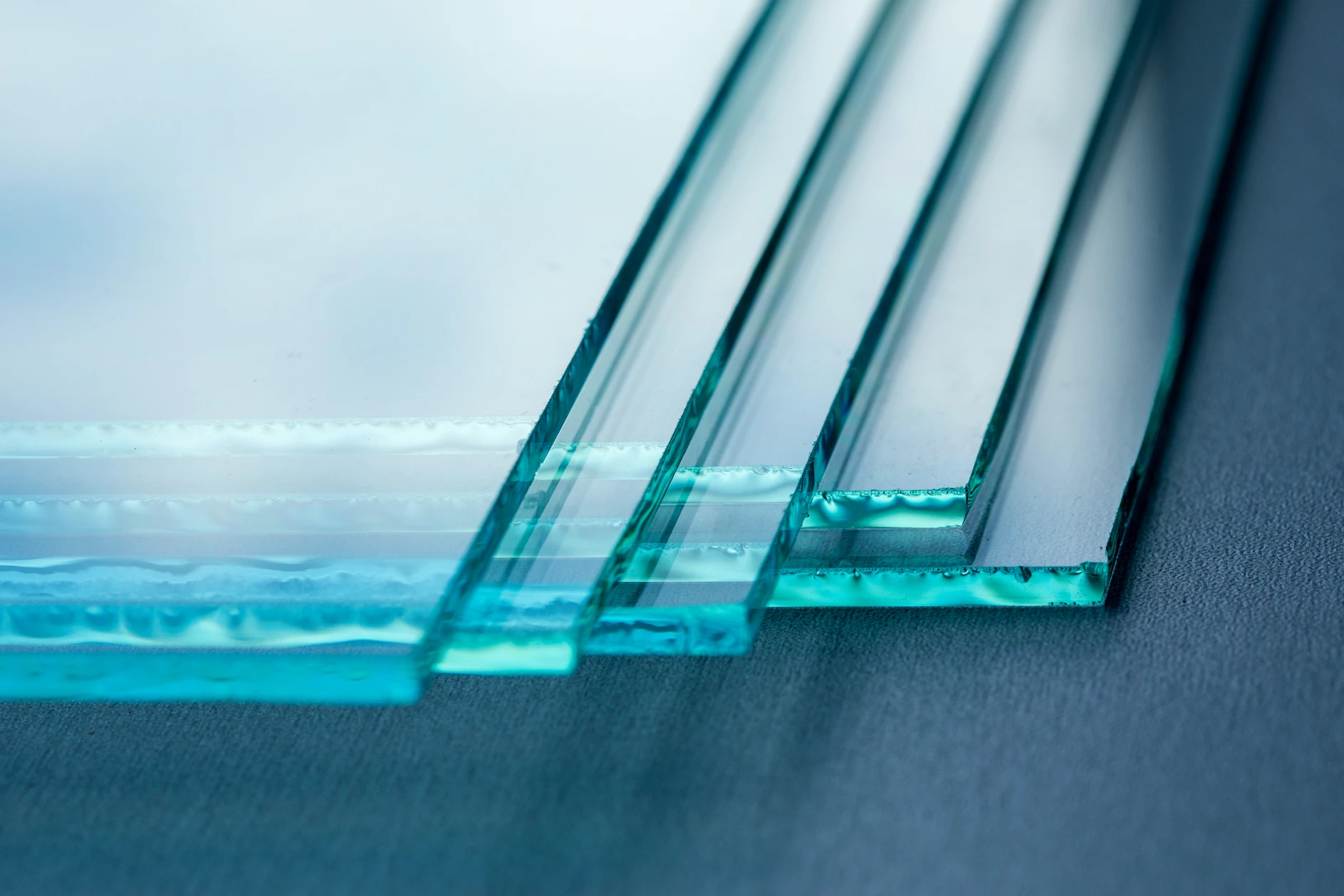

Float glass sheets have revolutionized the glass manufacturing industry, providing an unmatched blend of clarity, uniformity, and versatility. Unlike traditional glass-making techniques, the float glass process involves molten glass floating atop a bed of molten tin, creating smooth, uniform panes devoid of distortions. This meticulous production method results in high-quality glass ideal for a myriad of applications, from windows and mirrors to solar panels and automotive glazing.

Personal experience working with float glass sheets underscores their superior characteristics and adaptability. Their flawless surface makes them an excellent choice for architectural projects requiring expansive, uninterrupted views without compromising on structural integrity. The sheets' capacity to undergo additional processing, such as coating and tempering, enhances their utility further, offering options for customizing thermal and acoustic insulation properties. As an architect, using float glass has allowed the creation of buildings that are both aesthetically pleasing and energy-efficient, amplifying natural light while maintaining desired temperatures.

In the realm of expertise, understanding the manufacturing nuances of float glass is crucial. The process is a marvel of industrial engineering, relying on precise temperature controls and a controlled environment that minimizes deviations, resulting in a product of exceptional quality. Moreover, advancements in this sector continue to push the boundaries, with innovations such as thinner sheets that do not sacrifice strength, expanding the possibilities for design and application.

Authoritativeness in the glass industry is greatly supported by the trust placed in float glass sheets. Their consistent quality and reliability are backed by extensive research and development from leading manufacturers, ensuring that all regulatory and safety standards are not just met but exceeded. The widespread adoption by architects and engineers worldwide speaks volumes about their dependable performance in meeting the demands of modern construction and design projects.

float glass sheet

Trustworthiness is another pivotal aspect of float glass sheets, particularly in safety applications. When processed into tempered glass, these sheets gain heightened strength and safety features, fragmenting into small, less harmful pieces upon impact, which is essential for cars and high-rise building facades.

Choosing float glass reflects a commitment to safety and quality, reassuring stakeholders of its dependability.

For consumers and industry professionals considering float glass sheets, it's not merely a purchase; it's an investment in quality and innovation. The sheets' diverse applications prove invaluable in fostering sustainable practices, offering solutions that align with green building standards. By minimizing energy consumption through enhanced insulative properties, they contribute to reducing carbon footprints, further cementing their role in advancing eco-friendly building initiatives.

In conclusion, float glass sheets stand as a testament to high-quality engineering and innovation in the glass industry. They symbolize a future where design meets functionality without compromise, ensuring that whether it is in homes, offices, or industrial complexes, the benefits of clarity, strength, and efficiency are universally accessible.