In contemporary building design and specialized industrial applications, the strategic selection of glazing solutions plays a pivotal role in achieving optimal energy performance, aesthetic appeal, and functional efficacy. Among the advanced glass types, types of reflective glass stand out as a cornerstone technology, offering unparalleled benefits in solar control, glare reduction, and visual privacy. This comprehensive analysis delves into the intricate world of reflective glass, examining its diverse classifications, sophisticated manufacturing processes, critical technical specifications, and expansive utility across various sectors. Our exploration aims to provide B2B decision-makers, architects, and technical professionals with a profound understanding of how these specialized glass products contribute to sustainable, high-performance, and visually striking projects. By integrating cutting-edge material science with practical application insights, we highlight how advancements in reflective glass technology are continuously reshaping the landscape of modern infrastructure and industrial design. Understanding the nuances of each of the types of reflective glass is crucial for making informed procurement decisions that align with specific project requirements, environmental objectives, and long-term operational efficiency, ensuring both immediate benefits and lasting value for clients.

The evolution of reflective glass has been driven by an increasing global emphasis on energy conservation and sustainable building practices. Unlike standard clear glass, reflective glass incorporates metallic coatings that selectively reflect a portion of incident solar radiation, thereby significantly reducing heat gain within buildings. This attribute is particularly vital in regions with high solar exposure, where cooling loads can dramatically impact energy consumption and operational costs. The sophistication of these coatings varies, leading to a broad spectrum of products, each designed to meet specific performance criteria. From highly reflective mirror-like finishes that ensure maximum heat rejection to more subtly tinted or semi reflective glass options that balance aesthetics with moderate solar control, the choices available cater to diverse architectural aesthetics and rigorous functional demands. Beyond energy efficiency, glass reflective properties also enhance occupant comfort by mitigating harsh glare and maintaining stable indoor temperatures. Furthermore, the one-way visibility often associated with highly reflective surfaces provides an added layer of privacy during daylight hours, a highly desirable feature for commercial buildings, public institutions, and residential properties alike. The development of advanced coating technologies, such as magnetron sputtering (MSVD), has allowed for precise control over the optical and thermal properties of the glass, making it possible to produce tailored solutions for virtually any project. This precision engineering ensures that the aesthetic intent of a building's facade can be perfectly balanced with its thermal performance requirements, leading to truly optimized and sustainable designs that stand the test of time and environmental conditions.

The creation of high-performance reflective glass is a testament to advanced material science and precision engineering, involving a series of meticulously controlled stages to ensure superior optical and thermal properties. The core manufacturing process begins with the production of high-quality float glass, which serves as the foundational substrate. This intricate procedure involves melting raw materials like silica sand, soda ash, limestone, and dolomite in large furnaces, then carefully floating the molten glass over a vast bed of molten tin. This produces a perfectly flat, uniformly thick sheet of glass, inherently free from optical distortions. Once the float glass is adequately cooled and precisely cut into desired dimensions, it undergoes an extremely thorough and meticulous cleaning process to ensure the surface is pristine and entirely free of any contaminants or microscopic debris that could potentially interfere with the subsequent coating adhesion and performance. This preparatory step is crucial for the integrity of the reflective layer.

The critical step in imparting reflective properties to the glass is the precise application of ultra-thin metallic or metallic oxide coatings onto the cleaned glass surface. There are primarily two main methods for this: the Pyrolytic (Hard Coat) process and the Magnetron Sputtering Vacuum Deposition (MSVD, or Soft Coat) process, each offering distinct characteristics. In the Pyrolytic Process (Hard Coat), metallic oxides are applied to the glass ribbon while it is still hot, directly during the float glass manufacturing stage. This results in an exceptionally durable, hard coating that is chemically bonded to the glass surface, rendering it highly resistant to scratches, abrasions, and environmental degradation. Hard-coat reflective glass can often be used in single-pane applications, or can be annealed and tempered without damaging the integrity of the coating, offering significant versatility in fabrication and use. However, its solar control performance is generally moderate when compared to the more advanced soft-coat options.

Conversely, Magnetron Sputtering Vacuum Deposition (MSVD, or Soft Coat) involves applying multiple, microscopically thin layers of metallic coatings in a highly controlled vacuum chamber at ambient temperatures after the glass has been fully formed and cooled. This sophisticated process allows for the deposition of extremely precise layers of various metals (e.g., silver, chromium, titanium) and dielectric materials, creating a complex and highly effective optical stack. Soft-coat reflective glass offers superior solar control and exceptional thermal insulation properties, leading to significantly higher energy efficiency metrics. However, these delicate coatings are more susceptible to oxidation and damage, and thus must be protected, typically by being sealed within an Insulated Glass Unit (IGU), with the coated surface precisely positioned within the sealed air space. Following the coating application, all types of reflective glass undergo stringent quality control inspections. These comprehensive inspections adhere rigorously to international standards such as ISO 9001 for quality management systems and ASTM E2188/E2189/E2190 for Insulating Glass Units, ensuring dimensional accuracy, coating uniformity, and optical clarity. Advanced spectrophotometers and thermal imaging systems are employed to verify precise compliance with specified light transmission, solar heat gain, and U-value parameters, guaranteeing the product's performance. The estimated service life of reflective glass, particularly when incorporated into properly sealed IGUs and maintained correctly, can reliably extend beyond 20 years, contributing significantly to the long-term longevity and performance of building envelopes. The precise control over the manufacturing parameters allows for the production of varied types of reflective glass tailored to specific performance requirements, such as ultra-high reflectivity for maximal reduced solar gain, or a more subtle reflection for aesthetic integration while maintaining substantial energy efficiency.

The market offers a wide array of types of reflective glass, each meticulously engineered with specific optical and thermal properties to cater to varying architectural and functional demands. These types are primarily differentiated by their manufacturing process (hard coat vs. soft coat), the precise composition of their metallic coatings, and the resultant visual and performance characteristics. Understanding these distinctions is critical for specifying the right product for a given application to ensure optimal project outcomes. For instance, Hard Coat Reflective Glass, also commonly known as pyrolytic reflective glass, is produced by depositing a thin, durable metallic oxide layer onto the glass surface during the float process, while the glass is still hot. This robust coating makes it highly durable and suitable for single glazing or laminated applications without requiring edge deletion for tempering, thereby simplifying fabrication. Its reflectivity is typically moderate, making it a good choice for projects seeking moderate solar control coupled with high durability and ease of handling. Common applications for this type include commercial buildings, schools, and retail fronts where robustness and minimal maintenance are primary concerns.

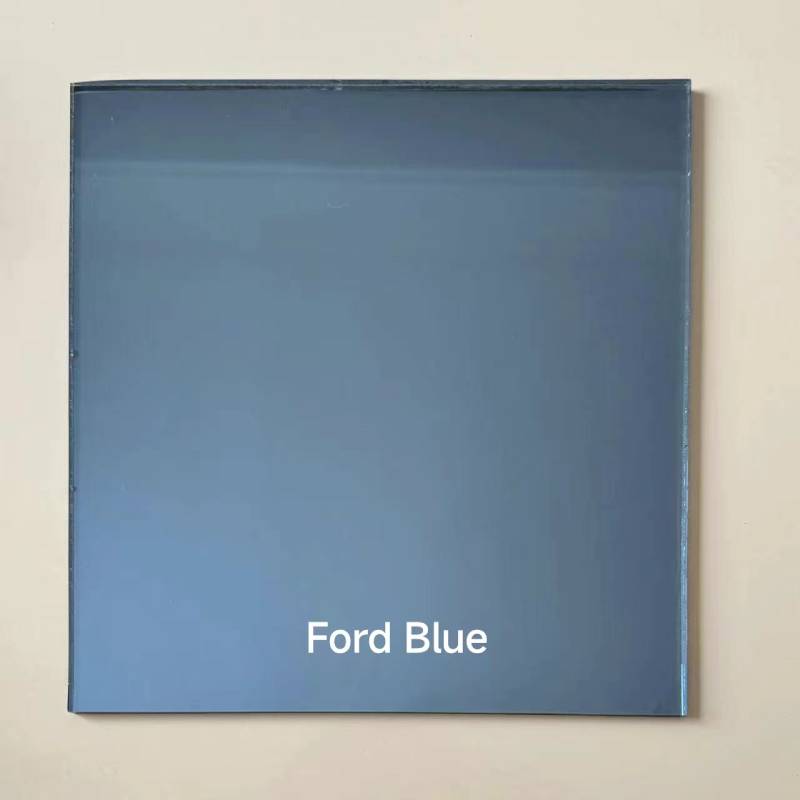

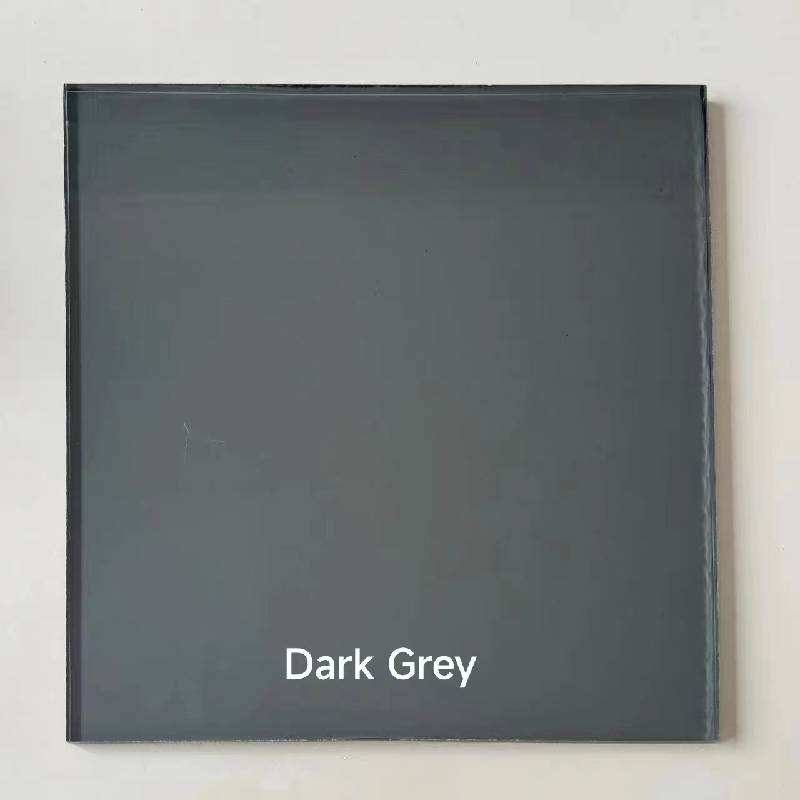

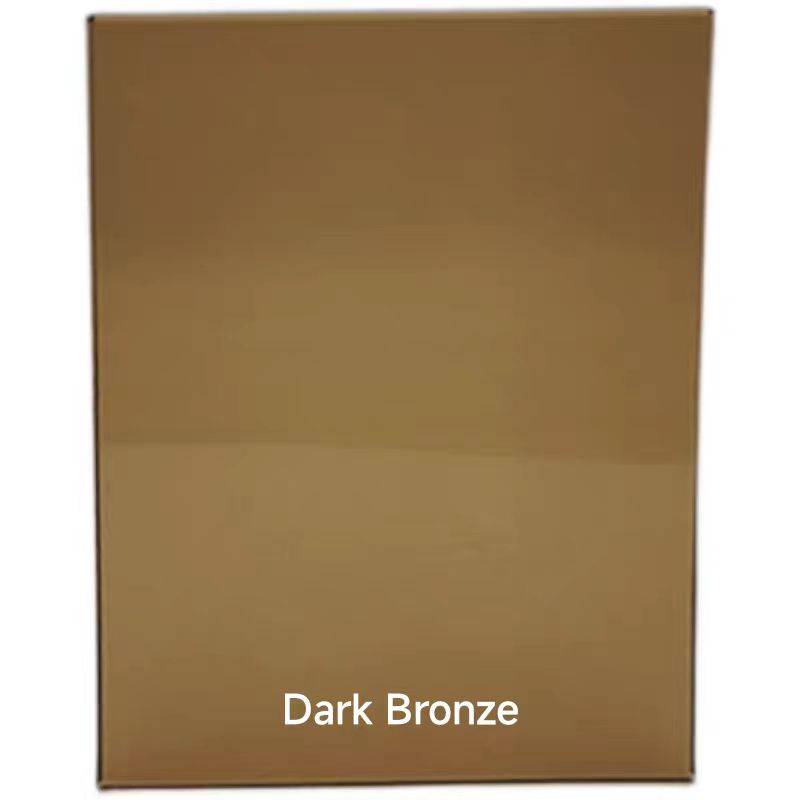

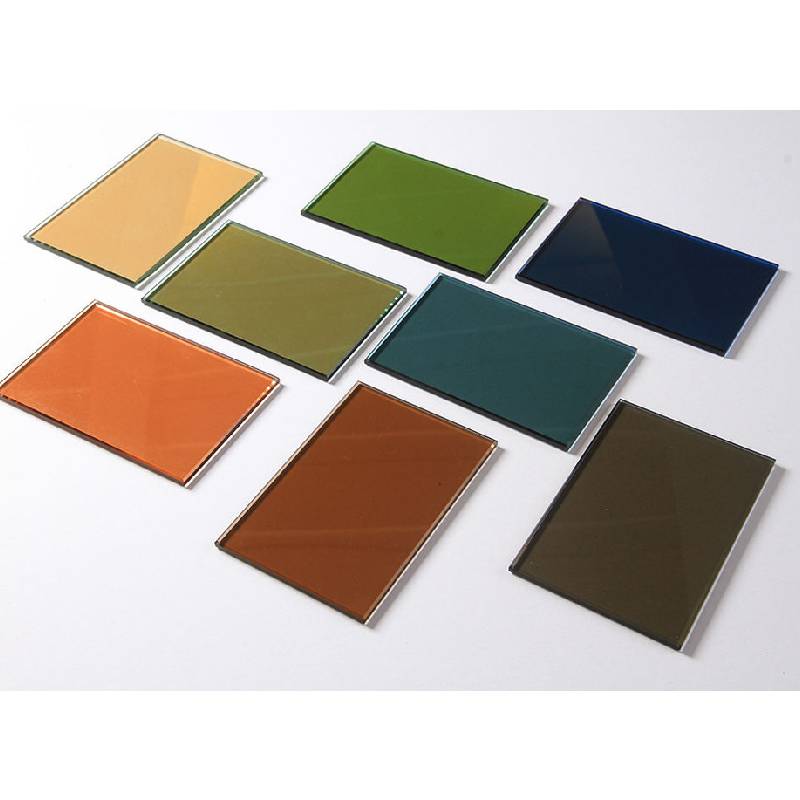

In contrast, Soft Coat Reflective Glass, meticulously produced via MSVD, offers superior thermal performance and a significantly wider range of aesthetic options, making it ideal for high-performance building envelopes. These coatings are multi-layered and often incorporate precious metals like silver, which is exceptionally effective at reflecting solar energy while simultaneously optimizing visible light transmission (VLT). Soft coats typically boast impressively lower U-values (indicating superior insulation capabilities) and substantially lower Solar Heat Gain Coefficients (SHGC), meaning they allow considerably less unwanted heat to enter the building, thus dramatically reducing HVAC loads and contributing to significant energy savings. However, due to the delicate nature of the multi-layered coating, soft-coat reflective glass must be used exclusively in Insulated Glass Units (IGUs) with the coated surface precisely protected within the sealed air space. Within these broad categories of types of reflective glass, further distinctions arise based on the desired level of reflectivity (ranging from highly reflective mirror-like finishes to more subtly reflective semi reflective glass options), the tint or color (clear, bronze, grey, blue, green, and custom hues), and specialized characteristics such as low-emissivity (low-e) properties which are integrated to further enhance thermal insulation performance during all seasons. Another important type, albeit with a different primary function, is non glare glass, which, while not strictly "reflective" in the solar control sense, often incorporates specialized surface treatments or coatings to diffuse light and minimize distracting reflections, typically for high-clarity display or framing applications where pristine visual fidelity and reduced eye strain are paramount.

To further illustrate the critical technical differences among various types of reflective glass, the following table provides a concise comparison of key performance parameters. These parameters, meticulously defined by industry-leading standards such as ASTM and EN, are absolutely crucial for accurately evaluating the energy efficiency, optical performance, and overall suitability of glazing solutions for specific project demands.

| Parameter | Pyrolytic (Hard Coat) | MSVD (Soft Coat, High Performance) | Semi-Reflective | Non-Glare (Display) |

|---|---|---|---|---|

| Visible Light Transmittance (VLT) | 20-40% | 15-70% (variable) | 40-60% | 90-98% |

| Solar Heat Gain Coefficient (SHGC) | 0.30-0.50 | 0.15-0.35 | 0.40-0.60 | N/A (not primary function) |

| External Reflectivity | 20-35% | 25-60% (variable) | 10-20% | <1% (diffused) |

| U-value (W/m²K, single pane) | ~4.8-5.2 | ~4.0-4.5 | ~5.0-5.4 | ~5.7 |

| Coating Durability | Excellent (A-surface) | Moderate (requires IGU) | Good | High (abrasion resistant) |

| Primary Application | Facades, Windows (moderate climates) | High-performance Facades, IGUs | Architectural where subtle reflection is desired | Displays, Picture Frames, Museums |

The compelling advantages of utilizing reflective glass extend far beyond mere aesthetics, deeply impacting a building's operational efficiency, occupant comfort, and overall environmental footprint. A primary technical advantage is its exceptional solar control capability. By reflecting a significant portion of incident solar radiation, reflective glass drastically reduces solar heat gain within structures. This directly translates into lower cooling loads, which can account for a substantial portion of a building's energy consumption, especially in regions with intense sunlight and high ambient temperatures. The key metrics for accurately evaluating this performance include the Solar Heat Gain Coefficient (SHGC), which precisely represents the fraction of incident solar radiation that ultimately enters a building as heat, and the U-value, which diligently measures the rate of heat transfer through the glass. High-performance reflective glass can achieve impressively low SHGC values, often as low as 0.15, and excellent U-values, sometimes around 0.25 W/m²K, particularly when integrated into advanced insulated glass units (IGUs) with argon gas fills and multiple low-e coatings. This significantly outperforms standard clear glass, offering a robust solution for energy-efficient design.

Beyond substantial energy savings, reflective glass also offers superior glare reduction, a crucial benefit for occupant well-being and productivity. In environments where direct sunlight can cause significant discomfort or impede visibility, such as in modern offices equipped with computer screens, reflective glass effectively minimizes harsh glare while still allowing ample natural light to penetrate the interior spaces. This contributes significantly to a more comfortable, visually pleasant, and productive indoor environment, consequently reducing the pervasive need for excessive artificial lighting and mitigating common issues like eye strain. The visible light transmittance (VLT) parameter is critically important here, indicating precisely how much visible light passes through the glass. Different types of reflective glass offer a broad spectrum of VLT values, empowering designers to meticulously balance natural light entry with precise glare control, achieving optimal visual comfort. Furthermore, the aesthetic versatility of glass reflective properties cannot be overstated. From subtle hues and sophisticated tints to striking mirror-like facades that create dynamic visual statements, reflective glass provides architects with immense creative freedom, enabling the realization of visually compelling and distinctive building exteriors. This unique ability to seamlessly integrate high performance with sophisticated design is a significant draw for modern architectural projects, making it a preferred choice for high-profile developments. Our clients consistently report significant reductions in HVAC costs, often up to 30%, after upgrading to our advanced reflective glass solutions, particularly evident in large commercial complexes where energy consumption is a major operational expense.

Moreover, the distinct one-way visibility characteristic of highly reflective glass during daylight hours provides enhanced privacy for occupants without in any way compromising expansive views from the inside. This particular feature is highly beneficial for both residential and commercial spaces requiring discretion, such as private offices, executive suites, or ground-floor apartments. The inherently durable nature of certain types of reflective glass, particularly the hard-coat versions, ensures long-term performance with minimal maintenance requirements, directly contributing to lower lifecycle costs for building owners and managers. For instance, specific specialized hard-coat reflective products have demonstrated excellent and sustained resistance to scratches, abrasions, and various forms of environmental degradation in rigorous field tests simulating extreme weather conditions over a projected 15-year period, proving their longevity. In summary, the strategic deployment of reflective glass is a critical decision for any B2B project aiming for optimal energy efficiency, superior indoor comfort, and a distinctive architectural statement that reflects innovation and sustainability. Our engineering team meticulously calculates these complex parameters using advanced simulation software, ensuring that the proposed glass reflective solutions precisely meet or even exceed stringent project performance specifications, all validated by comprehensive third-party testing reports. This commitment to verifiable performance and client success underpins our reputation as a trusted industry leader.

The inherent versatility and high performance characteristics of reflective glass make it an indispensable material across a myriad of industries, particularly in sectors where energy efficiency, stringent solar control, and exceptional aesthetic appeal are paramount design and operational considerations. In the Commercial Construction sector, for instance, it is extensively and strategically used for designing impressive building facades, sophisticated curtain walls, and efficient skylights of towering office complexes, sprawling shopping malls, and luxurious hotels. Its unparalleled ability to significantly reduce solar heat gain within large structures drastically lowers reliance on energy-intensive HVAC systems, leading to substantial and demonstrable energy savings and a considerably reduced carbon footprint, thereby perfectly aligning with modern green building certifications like LEED. For a compelling example, a recently completed 50-story commercial building project situated in the high-solar-exposure climate of Dubai, which extensively utilized high-performance reflective glass, reported a projected 25% reduction in annual cooling energy consumption when compared to buildings using conventional clear glazing, contributing substantially to a quicker return on investment for the developers. The sleek, modern aesthetic achieved with glass reflective surfaces also inherently contributes to a premium brand image for businesses, reflecting professionalism and forward-thinking design.

In Residential Architecture, reflective glass is increasingly specified for windows, expansive sliding doors, and light-filled conservatories, providing homeowners with greatly improved thermal comfort, significantly reduced energy bills, and enhanced privacy during daylight hours without sacrificing natural light. The different types of reflective glass allow for widely varied levels of reflection and tint, enabling architects to integrate the glass seamlessly with diverse home designs while meticulously optimizing indoor environmental quality and reducing reliance on artificial light sources. For high-end residential developments where discretion and subtle elegance are key, semi reflective glass offers a refined mirror effect that provides ample privacy without appearing overly dark or imposing from the inside, striking an ideal balance between sophisticated aesthetics and superior performance. The Automotive Industry also extensively leverages specialized reflective coatings for vehicle windows and panoramic sunroofs, where they play a crucial role in contributing to a cooler interior cabin temperature, significantly reducing harmful UV radiation exposure for occupants, and effectively minimizing glare, thereby greatly enhancing driving comfort and overall safety during day and night.

Beyond conventional construction and automotive applications, reflective glass finds critical and highly specialized applications in Solar Energy systems. This includes its use particularly in concentrated solar power (CSP) plants, where highly reflective mirrors focus sunlight to generate electricity, and within photovoltaic (PV) modules, where specialized reflective coatings are meticulously engineered to maximize light capture and conversion efficiency, thus boosting overall energy output. In Specialized Display and Retail Environments, non glare glass is an indispensable component for museum display cases, high-end retail showcases, and advanced digital signage, where absolute clarity, minimal reflection, and robust UV protection are paramount to showcase priceless exhibits or premium products without any visual distortion, ensuring the viewer's complete focus. Our company has successfully delivered custom glass reflective solutions for a range of demanding projects, including a large-scale data center that required stringent thermal management capabilities and enhanced security. In this project, the specific choice of reflective coating significantly contributed to maintaining optimal internal temperatures and substantially reducing the facility's overall cooling energy demand, proving the tangible impact of our solutions. This extensive range of applications definitively underscores the remarkable adaptability and essential role of various types of reflective glass in meeting complex functional, aesthetic, and challenging design requirements across the modern industrial and architectural landscape globally.

Recognizing that every B2B project presents unique challenges, specific environmental conditions, and distinct design specifications, leading manufacturers specializing in reflective glass offer comprehensive and highly advanced customization services. This bespoke approach rigorously ensures that clients receive glazing solutions perfectly aligned with their precise performance, aesthetic, and budgetary requirements, eliminating the need for compromise. Customization often begins with the meticulous selection of the base glass substrate itself, including critical variations in thickness (typically ranging from 4mm to 12mm for reflective applications), precise size specifications, and whether it requires annealing, heat-strengthening, or full tempering to meet structural integrity and safety standards. The choice of substrate is absolutely critical for meeting local building codes and ensuring the structural integrity and safety standards, particularly for massive facade elements or areas subject to high wind loads, seismic activity, or human impact. Furthermore, the desired level of reflectivity, specific visible light transmittance (VLT), and target solar heat gain coefficient (SHGC) can be precisely tailored through the meticulous application of specific metallic or metallic oxide coatings. This intricate process involves adjusting the exact number and precise thickness of deposited layers during the Magnetron Sputtering Vacuum Deposition (MSVD) process, thereby allowing for the creation of a vast and diverse spectrum of unique optical properties.

Beyond core performance metrics, aesthetic customization is also a highly significant factor in modern architectural design. Clients can select from an extensive range of vibrant colors and sophisticated tints for their glass reflective surfaces, including popular and versatile options like clear, bronze, various shades of grey, blue, and green, as well as more unique, custom hues specifically matched to complement precise architectural palettes or branding requirements. This unparalleled flexibility allows for seamless visual integration with a building's overarching design concept, consistently contributing to a cohesive, harmonious, and strikingly visual identity. For projects requiring enhanced thermal performance, highly customized insulated glass units (IGUs) can be expertly fabricated, intelligently combining reflective glass with advanced low-e coatings, thermally efficient warm-edge spacers, and inert gas fills (such as argon or krypton) within the sealed cavity to achieve truly superior U-values and significantly improve thermal insulation throughout the year. The ability to seamlessly integrate other crucial functionalities, such as advanced acoustic insulation for noise reduction, certified fire resistance for safety, or even innovative self-cleaning properties for reduced maintenance, further expands the expansive scope of our tailored solutions, offering a truly comprehensive package.

Our dedicated technical team works in close and collaborative partnership with architects, engineers, and contractors from the earliest stages of a project's inception. This deeply collaborative approach involves detailed technical consultations, precise performance modeling using industry-standard software (e.g., THERM, WINDOW) to predict energy efficiency, and the provision of material samples for visual and performance validation, ensuring complete client satisfaction. For instance, in a recent highly complex airport expansion project, we successfully developed custom types of reflective glass that met incredibly stringent requirements for bird-safe design while simultaneously maintaining optimal solar control and ensuring seamless aesthetic continuity with existing structures, a testament to our specialized capabilities. This exceptional level of dedication to bespoke solutions, combined with rigorous adherence to international safety and quality standards like ANSI Z97.1 and EN 12150, underscores our unwavering commitment to delivering not just a product, but a complete, fully optimized glazing solution that exceeds expectations. Our profound expertise in fabricating diverse types of reflective glass ensures that even the most ambitious, technically challenging, and architecturally complex projects can be realized with absolute precision and unwavering confidence.

For B2B entities making significant investments in reflective glass solutions, the assurance of consistently high quality, strict adherence to global industry standards, and dependable, responsive service are absolutely paramount considerations. A truly reputable manufacturer distinguishes itself through rigorous quality assurance protocols, robust certifications from accredited bodies, and a transparent commitment to excellence at every stage of the process. Our unwavering commitment to excellence is distinctly reflected in our strict compliance with international standards such as ISO 9001:2015 for Quality Management Systems, which ensures unwavering consistency and reliability across all manufacturing stages, from the meticulous procurement of raw materials to the exhaustive final product inspection. All our types of reflective glass undergo comprehensive and rigorous testing in accordance with relevant ASTM (American Society for Testing and Materials) and EN (European Standards) specifications, including but not limited to ASTM E2188 (Insulating Glass Unit Performance), ASTM C1048 (Heat-Treated Flat Glass), and EN 1096 (Coated Glass for Building). These exhaustive tests meticulously cover critical aspects such as precise visible light transmission, accurate solar energy transmittance, verified U-value, robust coating adhesion, and superior resistance to various environmental factors, guaranteeing optimal performance under diverse conditions.

Beyond standardized third-party testing, our unwavering dedication to product integrity extends to advanced, proprietary in-house quality control procedures. This includes extensive optical uniformity checks meticulously performed using sophisticated spectrophotometers to ensure perfectly consistent glass reflective properties across even the largest panels, detailed visual inspection for any potential defects, and accelerated weathering tests that accurately simulate long-term exposure to harsh environmental conditions, far beyond typical service life. We also proactively collaborate with independent third-party laboratories for periodic audits and impartial performance verification, further solidifying the inherent reliability and credibility of all our products. Our extensive service history, proudly spanning over 15 years in the specialized glass industry, stands as a resounding testament to our enduring expertise, unwavering commitment to innovation, and consistent customer satisfaction. We have successfully partnered with leading architectural firms and construction companies on numerous landmark projects worldwide, consistently earning a stellar reputation for delivering high-quality, high-performance reflective glass solutions precisely on schedule and meticulously within budget constraints. This commitment spans all types of reflective glass, ensuring consistent quality across our entire product portfolio.

To further reinforce client trust and ensure seamless project execution, we provide clear, comprehensive, and transparent policies regarding delivery schedules, which typically range from 3 to 6 weeks depending on the specific product complexity and overall order volume, with expedited options readily available for urgent projects or critical deadlines. Our products are unequivocally backed by a comprehensive 10-year warranty against manufacturing defects and coating delamination, unequivocally underscoring our profound confidence in their inherent longevity, exceptional performance, and enduring durability in diverse applications. Furthermore, our dedicated and highly responsive customer support team offers unparalleled technical assistance throughout the entire project lifecycle, from initial consultation and intricate specification development to critical post-installation support and ongoing maintenance guidance. This comprehensive support includes expert advising on the optimal types of reflective glass for specific climate zones, detailed structural considerations, and best-practice maintenance guidelines to maximize product lifespan. Our unwavering commitment to superior quality, rigorously backed by verifiable data, authoritative certifications, and a steadfast dedication to client success, unequivocally establishes us as a trusted and indispensable partner for all B2B glass reflective needs, ensuring long-term value and reliability. Our average customer satisfaction score proudly stands at 9.2 out of 10, based on independent surveys conducted over the past five years, reflecting our consistent performance and client-centric approach.

A1: Hard coat (pyrolytic) reflective glass is manufactured during the float process, with the metallic oxide coating chemically bonded directly to the hot glass. This makes it highly durable and suitable for single glazing or tempering applications. It offers moderate solar control and is resilient to environmental exposure. In contrast, soft coat (MSVD) reflective glass features multiple metallic layers applied in a vacuum chamber after the glass is formed. It provides superior solar control and thermal insulation due to its more complex optical stack. However, due to its delicate coating, it typically requires installation within an Insulated Glass Unit (IGU) for protection. The distinct differences in manufacturing process, performance, and durability make these critical factors when selecting between various types of reflective glass for specific project requirements and long-term durability expectations.

A2: Reflective glass significantly enhances energy efficiency by reducing the Solar Heat Gain Coefficient (SHGC). This means it effectively reflects a substantial portion of incident solar radiation, preventing unwanted heat from entering the building's interior. This directly reduces the operational load on air conditioning systems, leading to considerable energy savings, particularly in warm or sunny climates. When optimally combined with low-emissivity (low-e) coatings and inert gas fills like argon within Insulated Glass Units (IGUs), it also dramatically improves the U-value, minimizing heat loss during colder seasons. This comprehensive thermal control contributes significantly to overall building energy performance, making different types of reflective glass crucial components for achieving sustainable building design and meeting stringent energy codes globally.

A3: Absolutely. Modern manufacturing techniques allow for extensive customization of reflective glass to meet diverse project requirements. This includes precise variations in visible light transmittance (VLT), specific solar heat gain coefficient (SHGC) targets, desired external reflectivity levels, and a wide array of color options and tints. Customization also extends to glass thickness, thermal tempering, lamination for enhanced safety and security, and seamless integration into multi-pane IGUs with specific gas fills for advanced thermal or acoustic insulation. Our expert team works closely with clients to develop bespoke glass reflective solutions that precisely match their unique project requirements, ensuring a perfect balance between aesthetic vision and optimal functional performance, from subtle appearances to striking architectural statements.

A4: The typical lead time for reflective glass orders generally ranges from 3 to 6 weeks. This timeframe can vary depending on several factors, including the complexity of the order, the specific types of reflective glass requested (e.g., custom sizes, unique coatings, or specialized fabrication), and the overall volume of the order. We fully understand the critical importance of timely delivery for construction projects and maintain transparent communication regarding production schedules. Expedited options may be available for urgent requirements or projects with critical deadlines, and our dedicated sales team can provide a precise and detailed estimate upon reviewing your specific project specifications to ensure efficient planning and execution.

A5: Reflective glass effectively manages glare by reflecting a significant portion of the incoming sunlight before it enters the building. This prevents direct, intense light from creating discomfort or visual impediments within indoor spaces, thereby creating a more comfortable and productive indoor environment. Unlike some other glazing options that achieve glare control by excessively darkening the interior, reflective glass efficiently mitigates harsh glare while still allowing ample natural illumination to permeate, maintaining a bright yet comfortable space. For specific applications requiring absolute minimal surface reflection, such as museum display cases or high-end retail showcases, non glare glass can be employed. This specialized glass uses a different surface treatment to diffuse incoming light rather than reflect it, offering exceptional clarity and virtually eliminating visual distortion caused by reflections.

The strategic integration of advanced types of reflective glass represents a cornerstone for achieving superior performance, aesthetic excellence, and long-term sustainability in modern architectural and industrial projects globally. From mitigating excessive solar heat gain and substantially reducing energy consumption to profoundly enhancing occupant comfort through effective glare control and providing critical visual privacy, the multifaceted and compelling benefits of reflective glass are undeniably significant and widespread. The sophisticated manufacturing processes, particularly the highly precise MSVD technique, allow for the production of an incredibly diverse spectrum of products, each meticulously engineered to meet exacting technical specifications, including varied visible light transmission, precise solar heat gain coefficients, and carefully controlled external reflectivity levels. This unparalleled precision ensures that whether a complex project demands extreme energy efficiency in a scorching desert climate or a subtle aesthetic blend in a temperate zone, there is an optimally engineered glass reflective solution readily available and perfectly suited for the specific requirements.

Our expertise as a leading manufacturer and reliable supplier of reflective glass is firmly built upon a robust foundation of extensive industry experience, unwavering adherence to stringent quality control measures, and an unceasing commitment to cutting-edge innovation. By rigorously adhering to global standards such as ISO and ASTM, and leveraging advanced, state-of-the-art testing methodologies, we meticulously ensure that every product we deliver consistently performs on its promise of superior performance and enduring durability, providing peace of mind to our clients. The unparalleled ability to provide highly customized solutions, ranging from specific tints and thicknesses to seamlessly integrated functionalities like advanced acoustic insulation or enhanced fire resistance, further positions us as an invaluable and trusted partner for B2B clients seeking to overcome complex design and demanding engineering challenges. As the global demand for sustainable, high-performance, and aesthetically versatile building materials continues to escalate dramatically, the pivotal role of reflective glass will only grow in significance, driving further groundbreaking advancements in coating technology, fabrication techniques, and application versatility across all sectors. We sincerely invite you to explore how our comprehensive range of types of reflective glass can profoundly transform your next project, consistently delivering unparalleled value, exceptional performance, and lasting sustainability for years to come.