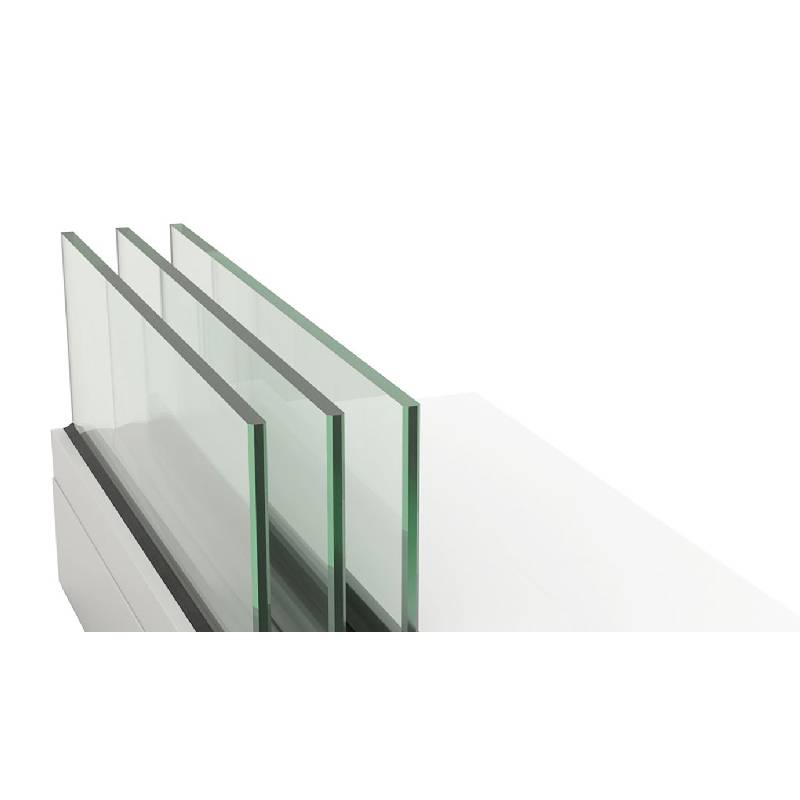

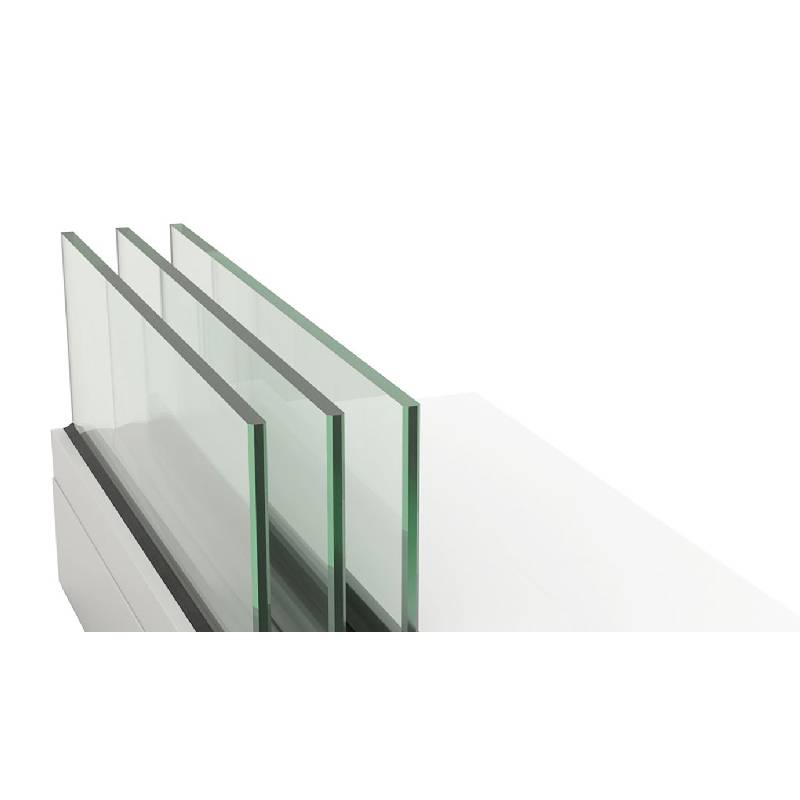

When considering premium materials for construction and design, 3mm float glass emerges as an exceptional choice, exemplifying a sophisticated blend of durability, versatility, and aesthetic appeal. As industries increasingly lean on high-quality materials, understanding the benefits, applications, and mechanisms of float glass technology is essential.

Float glass, a product of modern manufacturing ingenuity, is created by floating molten glass on a bed of molten metal, typically tin. This process results in a flawless, uniform sheet prized for its clarity and surface quality. The 3mm variant, albeit thin, embodies strength and reliability, making it suitable for a myriad of applications.

Professionals in the architecture and interior design realms have long appreciated 3mm float glass for its minimalist appeal and functionality. Its transparency allows for natural light transmission, enhancing energy efficiency while offering a sleek, modern aesthetic. Architects leverage its clarity and consistency in applications ranging from windowpanes to elegant partitions and facades, recognizing its capability to transform spaces with light and openness without compromising structural integrity.

In the realm of interior design, 3mm float glass finds ubiquitous use in furniture design and decor elements. Coffee tables, shelving, and cabinetry doors exemplify the stylish integration of float glass, providing both a contemporary look and practical benefits. Designers often opt for it due to its ability to seamlessly blend with different materials such as wood and metal, offering an elegant contrast that complements various interior themes.

Moreover, 3mm float glass's robustness despite its thinness makes it an optimal choice for certain safety applications. While tempered or laminated glass may be necessary for high-risk areas, the basic integrity and break resistance of float glass make it suitable for less demanding safety requirements where aesthetics cannot be compromised.

3mm float glass

Engineering and industrial sectors are not strangers to the advantages of float glass either. Its uniform thickness and clarity make it critical in the production of precise instruments and high-quality displays. In the growing field of solar panels, 3mm float glass serves as a front cover plate, balancing light transmittance with protective functions, thereby contributing to energy sustainability and efficiency.

From a manufacturing perspective, producing 3mm float glass requires precise control and expertise, underscoring the product’s sophistication. It involves rigorous quality control to maintain the consistency and stability of its physical properties, ensuring every sheet meets industry standards. This meticulous process speaks to the expertise and authoritativeness of manufacturers who supply float glass, reinforcing their reputation in the materials sector.

The environmental benefits of using float glass further enhance its appeal. As the industry moves towards sustainability, float glass manufacturers are innovating to reduce energy consumption and raw material usage in production. The recyclability of glass adds another layer to its environmental credentials, aligning with the global shift towards greener building practices.

In conclusion, 3mm float glass represents a fusion of elegance, functionality, and modern manufacturing practices. Its role in design, architecture, and technology underscores its versatility and indispensability in contemporary applications. As a trusted material, its continued use reflects a deep-seated reliability and excellence that aligns with both aesthetic aspirations and practical needs. For industry professionals and consumers alike, 3mm float glass is not just a material but an integral component of forward-thinking design and construction practices.