Understanding Float Glass Types A Comprehensive Guide

Float glass is a widely used material in a variety of industries, from construction and automotive to electronics and solar energy. It is renowned for its clarity, strength, and versatility. To thoroughly appreciate float glass, it's important to understand the different types available, their manufacturing processes, and their applications.

What is Float Glass?

Float glass is a type of flat glass that is produced using the float glass process, which was developed in the 1950s by Sir Alastair Pilkington. The process involves floating molten glass on a bed of molten tin, resulting in a smooth, flat surface. This technique ensures uniform thickness and superior clarity, making float glass an ideal choice for windows, mirrors, and decorative elements.

Types of Float Glass

1. Clear Float Glass This is the most common type of float glass. It has high transparency and is made from silica, soda ash, and limestone. Clear float glass is used extensively in residential and commercial buildings for windows and glass doors. Its neutral color and clarity make it suitable for various aesthetic and functional applications.

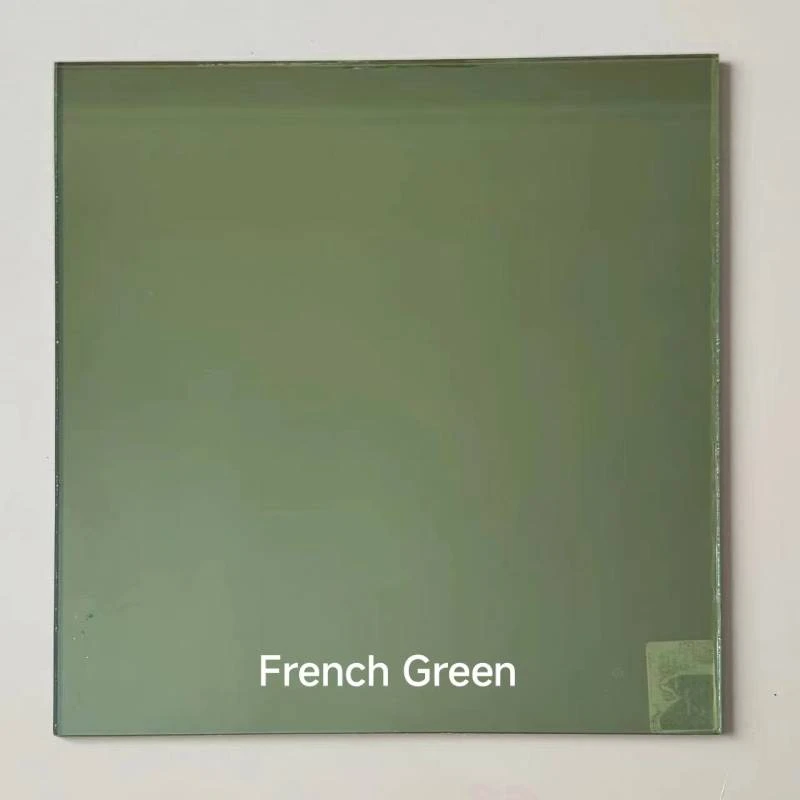

2. Tinted Float Glass Tinted float glass incorporates metal oxides during its production to reduce glare and heat. It is available in various colors, such as bronze, gray, and blue, allowing for more design flexibility while increasing privacy. Tinted glass is often used in commercial buildings and vehicles to control sunlight and improve energy efficiency.

3. Reflective Float Glass This type of glass features a reflective coating on one side, providing enhanced privacy and reducing solar heat gain. It is commonly used in high-rise buildings and office structures as it helps in minimizing glare while maintaining a modern aesthetic. The reflective properties also enhance energy efficiency by lowering cooling costs.

4. Low-E Float Glass Low emissivity (Low-E) float glass has a special metallic coating that reflects heat back into a building while allowing natural light to enter. This type of glass is particularly advantageous in regions with extreme temperatures, as it helps maintain a consistent indoor climate and significantly reduces energy costs. Low-E glass is popular in residential and commercial applications where energy efficiency is a priority.

5. Laminated Float Glass Laminated float glass is produced by sandwiching a layer of polyvinyl butyral (PVB) between two sheets of float glass. This type offers enhanced safety and sound insulation, reducing noise and the risk of shattering. It is commonly used in buildings, skylights, and in areas where safety is a concern, such as in schools and hospitals.

6. Tempered Float Glass This is float glass that has gone through a heating and cooling process to increase its strength. Tempered glass is much tougher than standard float glass and, when broken, shatters into small, less harmful pieces. It is widely used in facades, shower doors, and glass railings, where safety and durability are essential.

7. Frosted Float Glass Frosted float glass is created by sandblasting or acid etching the surface, which gives it a translucent appearance while maintaining light transmission. This type is often employed in bathrooms, offices, and conference rooms to provide privacy without sacrificing natural light.

Applications of Float Glass

Float glass is versatile and used in numerous applications

- Architecture and Construction It forms the base material for window panes, facades, and interior partitions. - Automotive Industry Float glass is used in car windows and windshields for its clarity and safety features. - Electronics Used in screens for televisions, computers, and mobile devices, where high transparency is necessary. - Solar Panels Float glass is utilized in solar energy systems, providing a protective cover for photovoltaic cells.

Conclusion

The various types of float glass cater to different needs and applications, reflecting advancements in technology and manufacturing processes. Understanding these types helps in making informed decisions for construction, design, and energy efficiency. As demand for sustainable and energy-efficient solutions continues to rise, float glass will remain an integral material across industries, offering both functional benefits and aesthetic appeal.