Understanding Float Glass Its Production, Properties, and Applications

Float glass is a widely used type of glass that has become a fundamental component in various industries, particularly in construction and automotive applications. Known for its clarity and smooth finish, float glass is a true innovation in glass manufacturing that revolutionized the way glass is produced. This article explores the production process, properties, and numerous applications of float glass, shedding light on why it holds such a significant place in modern architecture and design.

Production Process

The production of float glass began in the 1950s, with the method invented by Sir Alastair Pilkington, who introduced a revolutionary process that involved floating molten glass on molten tin. The process is relatively straightforward yet highly efficient. It starts with mixing silica sand, soda ash, and limestone, forming a batch that is then melted in a furnace at temperatures exceeding 1,600 degrees Celsius. This creates a molten glass.

Once melted, the molten glass is carefully poured onto a bed of molten tin. Since glass is less dense than tin, it floats on the surface, spreading uniformly to create a flat sheet. The use of tin is crucial, as it provides a smooth and even surface, which minimizes imperfections and allows for an even thickness. While the glass floats, it gradually cools and solidifies into a flat sheet. As it cools, it undergoes a process called annealing, where it is slowly cooled to relieve internal stresses. This results in high-quality glass with excellent optical properties.

Properties of Float Glass

Float glass is characterized by its remarkable transparency, smooth surface, and uniform thickness. One of its key features is its optical clarity; the glass allows light to pass through with minimal distortion. This makes it an ideal choice for applications where visibility is crucial, such as windows and display cases.

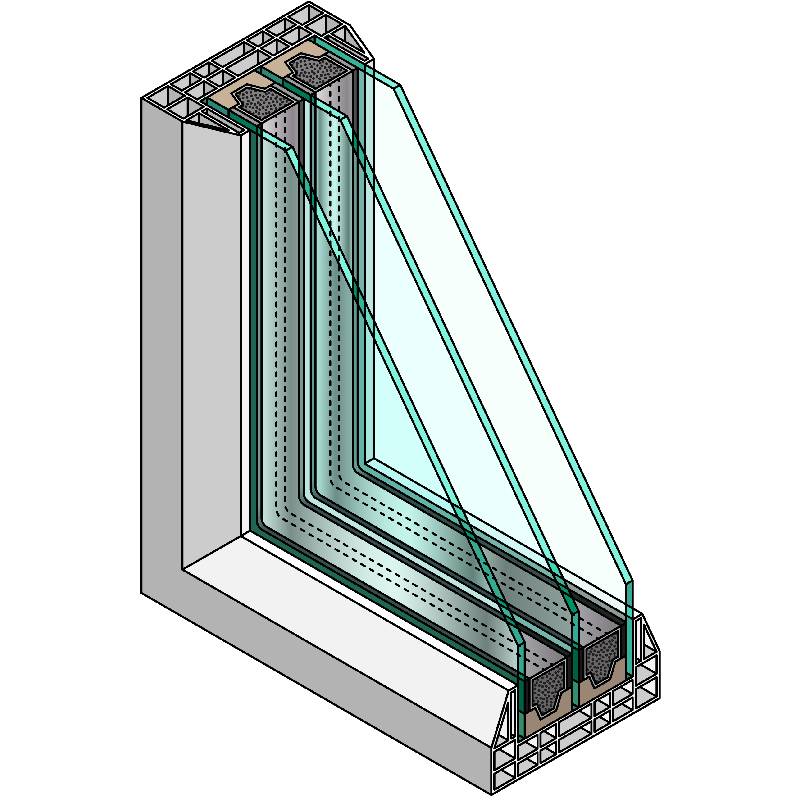

Additionally, float glass can be produced in varying thicknesses, typically ranging from 2 mm to 19 mm, allowing for flexibility in design and application. Its surface can also be treated to enhance properties such as thermal resistance and UV protection. Furthermore, float glass can be coated or laminated to improve strength and safety, especially in architectural applications.

Applications of Float Glass

The versatility of float glass lends itself to a wide array of applications. One of its most common uses is in building and construction. Float glass is extensively utilized for windows, facades, and doors in residential and commercial buildings. It provides natural light while offering sound insulation and energy efficiency. Architects appreciate float glass for its aesthetic appeal and the ability to achieve a modern and sleek look in building designs.

In addition to architectural uses, float glass is also prevalent in the automotive industry. It is used for windshields and windows due to its clarity and strength. Float glass can withstand the rigors of weather conditions while ensuring passenger safety.

Moreover, float glass is used in the production of mirrors, table tops, and glass shelving. Its aesthetic qualities and ease of maintenance make it a popular choice for home and office furnishings.

Conclusion

In conclusion, float glass is a remarkable material that has significantly impacted various industries. Its production process, rooted in innovation, results in a product that boasts exceptional clarity, smoothness, and versatility. From construction and automotive applications to household items, float glass plays an integral role in contemporary design and functionality. As technology advances, we can expect further enhancements in the production and application of float glass, ensuring its continued relevance in our daily lives. Whether it’s the structure of a towering skyscraper or the sleek finish of a car window, the influence of float glass is omnipresent, showcasing the beauty and utility of this extraordinary material.