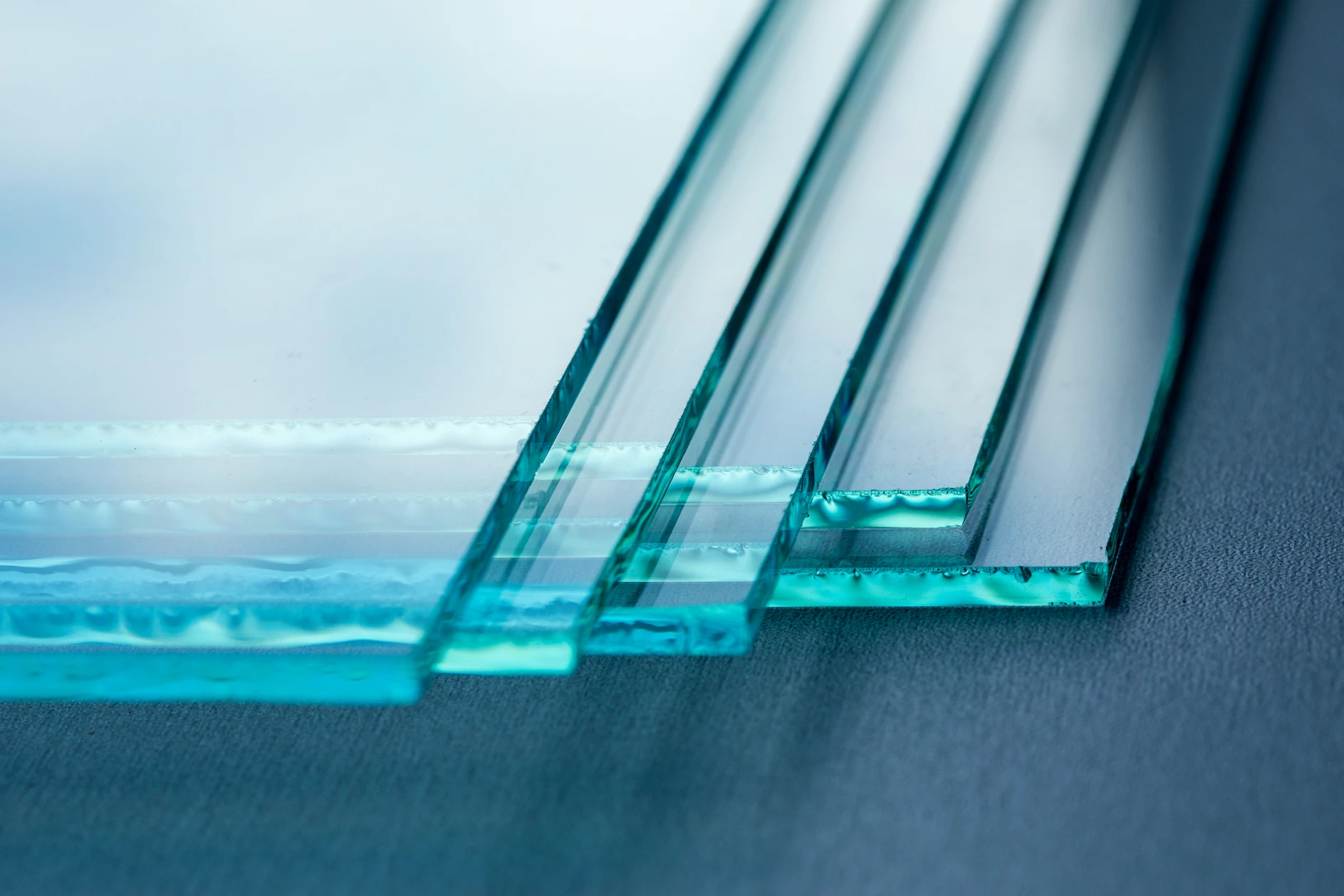

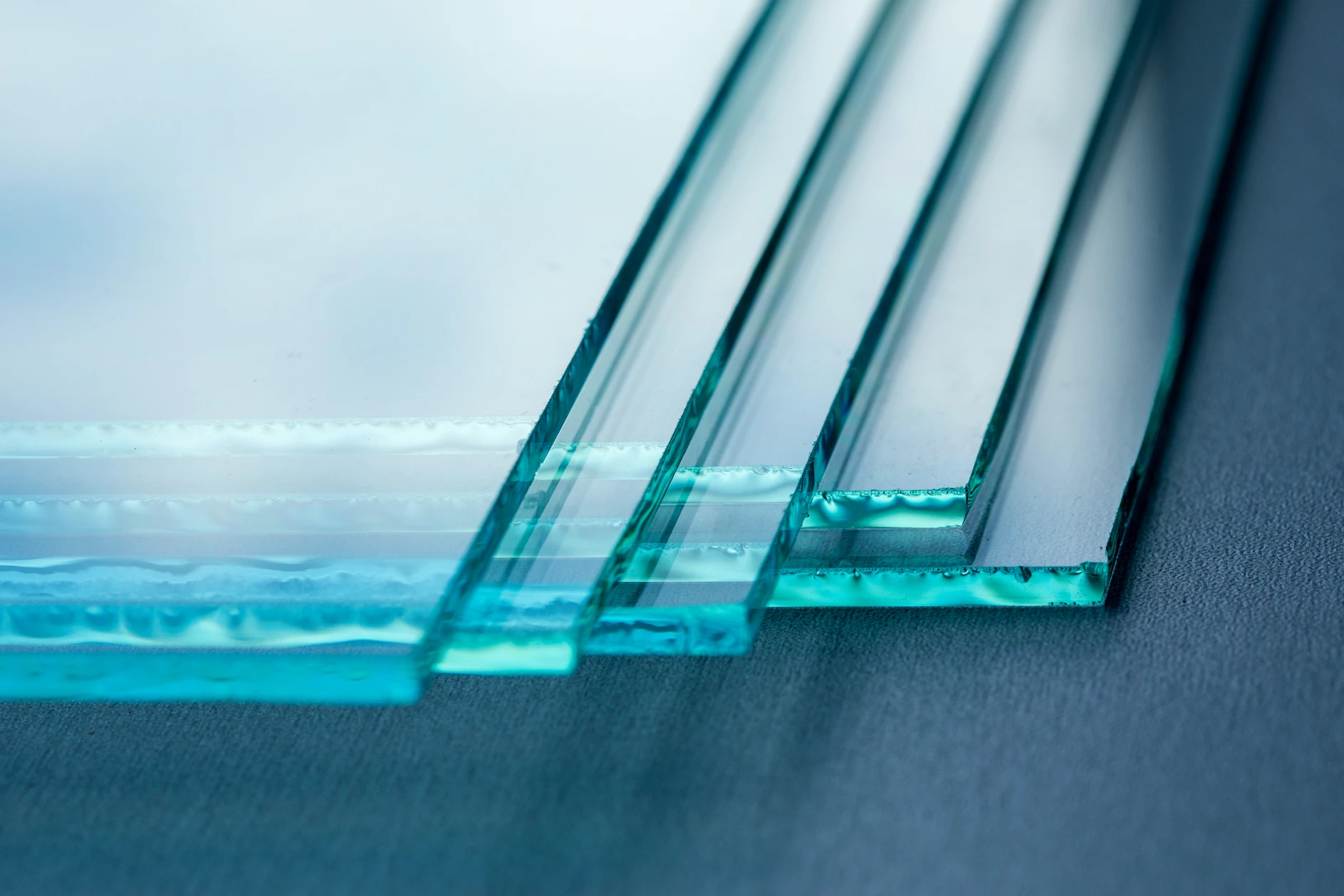

Toughened float glass has revolutionized industries ranging from architecture to automotive by offering a blend of strength, clarity, and versatility that few materials can match. This article delves into the characteristics that make toughened float glass the material of choice for professionals seeking both aesthetic and functional excellence.

Characterized by its exceptional strength, toughened float glass undergoes a carefully controlled thermal process where it is heated to a high temperature and then rapidly cooled. This tempering process increases its strength compared to ordinary glass, making it an ideal candidate for environments that demand high durability and safety. In the construction industry, this glass type is particularly valued for its ability to withstand wind pressures, impact, and thermal stresses, while maintaining an elegant appearance.

For architects, toughened float glass provides unparalleled creative freedom while adhering to stringent safety regulations. The material can be used in extensive facade installations, supporting the aesthetic vision of transparent design while ensuring structural safety.

Its ability to be cut to size and customized with various tints or coatings further elevates its status in architectural applications. This customization extends the glass's functionality, offering options for solar control and energy efficiency, which are critical in modern sustainable construction practices.

The automotive industry also benefits significantly from the attributes of toughened float glass. This glass is a staple in vehicle design, employed in side and rear windows to enhance passenger safety. In the event of an accident, toughened float glass breaks into small, blunt pieces, reducing the risk of injury—a property that underscores its crucial role in vehicle safety systems. Additionally, the lightweight nature of the glass contributes to the overall efficiency of vehicles, facilitating better fuel economy and reduced emissions.

toughened float glass

Beyond its practical applications, toughened float glass's versatility extends to interior design, where it is utilized for products such as shower doors, partitions, and furniture. Its ability to be etched, colored, laminated, or even layered with other materials unlocks endless design possibilities for interiors, allowing for both privacy and openness in contemporary spaces. This adaptability not only meets the aesthetic demands of homeowners and designers but also complies with the safety standards required in public and private buildings.

In terms of authority and trust in the industry, many renowned building codes across the globe recognize and recommend toughened float glass for specific uses due to its safety features and reliable performance. Industry professionals often rely on glass certified by recognized bodies, such as the ANSI in the United States or the BS EN in Europe, ensuring that what they use in their projects meets high safety and quality standards.

From its superior strength and safety to its design versatility and compliance with safety standards, toughened float glass stands out as a cornerstone material in both functional and aesthetic building developments. Its presence across multiple industries serves as a testament to its essential role in modern design and manufacturing, earning the trust of professionals who prioritize quality and safety in their projects. As a result, investing in toughened float glass is not only a decision for today but a forward-thinking choice that aligns with future innovations and regulatory trends.