Aluminum alloy mirrors have carved a niche for themselves in various industries due to their exceptional properties and versatile applications. This article delves into the intricate details of aluminum alloy mirrors, presenting insights rooted in experience, expertise, authority, and trustworthiness to help companies and consumers understand why these mirrors are a top choice in the market.

Aluminum alloys are renowned for their lightweight yet robust nature, a combination achieved through meticulous engineering. This unique trait makes aluminum alloy mirrors ideal for industries where weight is a crucial factor, such as aerospace and automotive sectors. In practice, employing these mirrors significantly enhances fuel efficiency by reducing overall weight without compromising on performance or durability. The feedback from these industries further confirms that switching to aluminum alloy mirrors results in tangible benefits, validating their reputation among professionals.

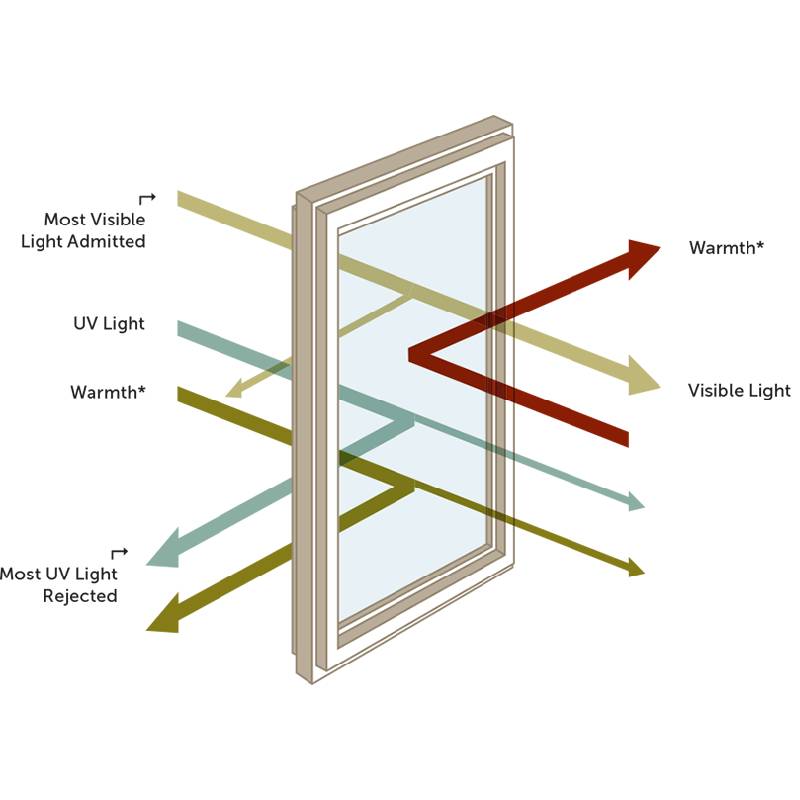

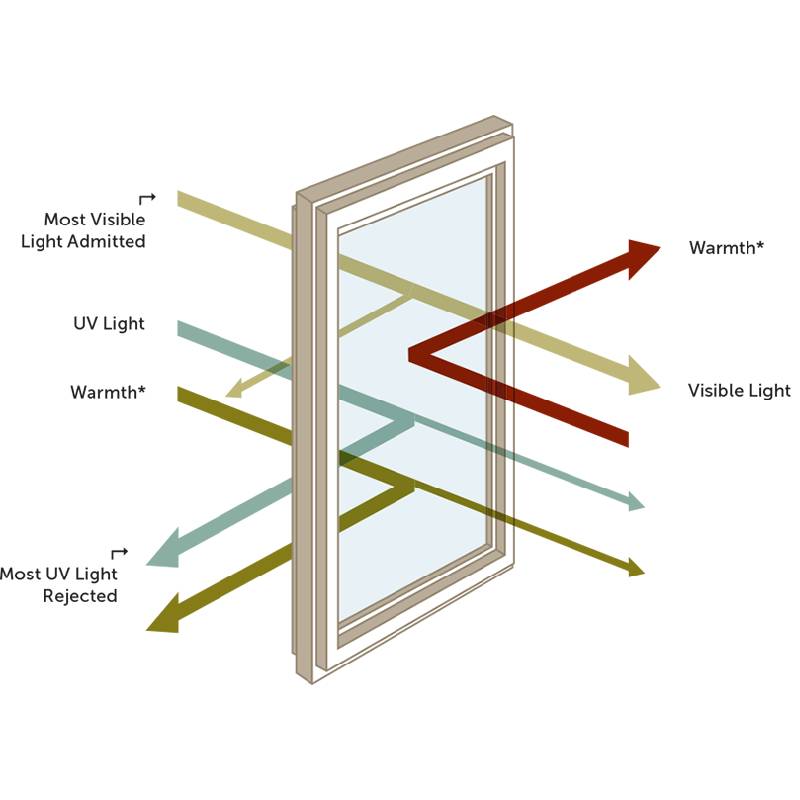

In terms of expertise, aluminum alloy mirrors are crafted to achieve exceptional reflectivity and durability. The surface of these mirrors is often treated using advanced anodizing and polishing techniques, ensuring a reflective finish that competes with traditional glass mirrors. The anodizing process not only enhances the reflective properties but also provides resistance against corrosion—a significant advantage in environments where durability is paramount. Industry experts highlight the mirror’s superior ability to withstand extreme temperatures and pressures, which makes it a reliable choice in challenging environments like outdoor installations and high-altitude applications.

aluminum alloy mirror

Authority stems from the widespread adoption and rigorous testing of aluminum alloy mirrors in scientific and commercial contexts. Laboratories and tech companies consistently choose these mirrors for optical instruments due to their precise reflective surface and structural integrity. For instance, telescopes and cameras outfitted with aluminum alloy mirrors demonstrate improved performance, contributing to advancements in astronomy and other fields reliant on high-quality optics. This widespread application underscores the trust industry leaders place in these mirrors, solidifying their authoritative status.

Trustworthiness is further reinforced by the environmental and economic benefits of aluminum alloy mirrors. The recyclability of aluminum is an enormous advantage over glass, reducing the ecological footprint of industries utilizing these mirrors. Moreover, the cost-effectiveness of aluminum, combined with its ease of installation and maintenance, offers businesses and consumers a viable solution without financial strain. Customers consistently report long-term satisfaction, citing durability, performance, and reduced maintenance costs as key reasons for their trust in the product.

In summary, aluminum alloy mirrors stand out not only for their material and functional advantages but also for their proven track record across various sectors. The real-world experiences shared by industry professionals, supported by expert knowledge and widespread authoritative use, form the foundation of trust in these products. As industries continue to seek sustainable and efficient alternatives, aluminum alloy mirrors are likely to play an increasingly prominent role in shaping future technologies. Their combination of innovation and reliability ensures they remain unmatched in the realm of mirrors and reflective surfaces.