Understanding the Cost of Mirror Glass Factors and Implications

Mirror glass is a vital component in various industries, from interior design to automotive applications. Understanding the cost of mirror glass is crucial for consumers, manufacturers, and builders alike. The price of mirror glass can vary significantly based on a multitude of factors, including the type of glass, production methods, thickness, and any additional coatings or treatments.

One of the primary factors affecting the cost of mirror glass is the type of glass used. Standard mirror glass is usually made from float glass, a type of glass made by floating molten glass on top of molten tin. This process creates a smooth surface that is ideal for reflecting images. However, specialty types of glass, such as low-iron glass, can increase costs due to their higher production standards and the purity of the materials used. Low-iron glass allows for brighter and clearer reflections but is generally more expensive than standard glass.

Another important factor that influences the cost is the thickness of the glass. Thicker glass not only provides a sturdier surface but also enhances durability. For example, a standard mirror may be 3mm thick, while other applications might require glass that is 6mm or more. As the thickness increases, so does the material cost, affecting the overall price of the mirror.

Production methods also play a significant role in determining the cost of mirror glass. Traditional manufacturing processes can be labor-intensive and time-consuming, which may drive up costs. On the other hand, advancements in technology have led to more efficient production techniques, which can help reduce costs over time. However, these technologies are often accompanied by higher initial investments, making it a balancing act for manufacturers trying to keep prices competitive while maintaining quality.

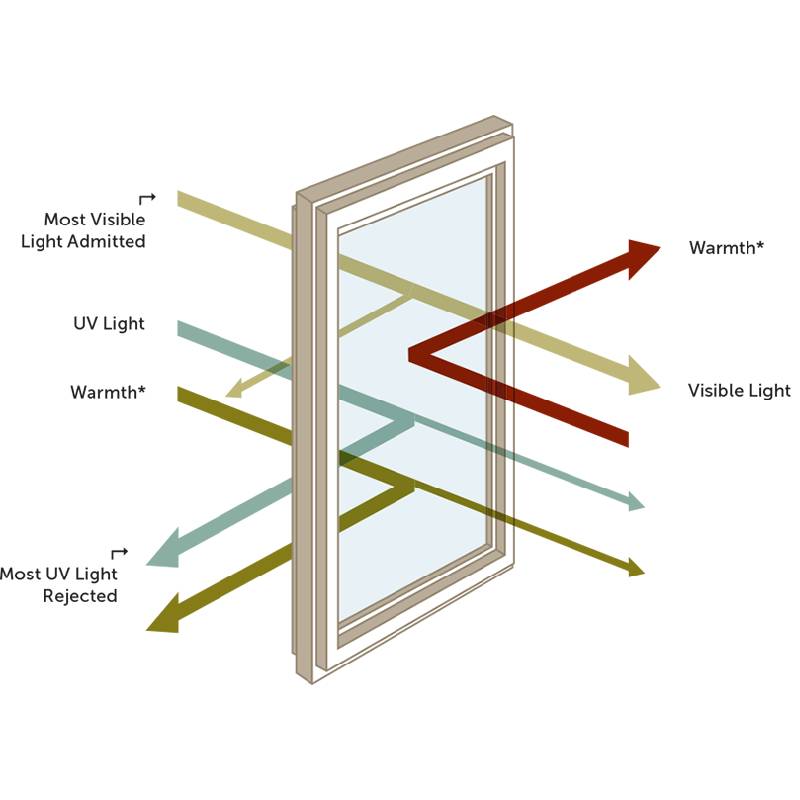

Coatings and additional treatments add another layer of complexity to the pricing of mirror glass. Many mirrors come with protective coatings to enhance durability and resistance to corrosion, as well as to provide benefits such as anti-fog or anti-scratch properties. Mirrors designed for specific environments, such as bathrooms or outdoor spaces, may be treated with special coatings to withstand humidity and temperature fluctuations. These enhancements can raise the price significantly based on the materials and processes involved.

Lastly, market demand and geographical location can influence the cost of mirror glass. In areas where there are high construction and design demands, prices may rise due to the increased competition for resources and materials. Additionally, transportation costs can affect final pricing, especially if the glass has to be shipped over long distances.

In conclusion, understanding the cost of mirror glass involves considering a variety of factors, including the type of glass, thickness, production methods, coatings, and market dynamics. For consumers and businesses alike, having a clear understanding of these factors can lead to informed purchasing decisions, ensuring that the investment in mirror glass aligns with both budgetary constraints and quality expectations. Whether it's for residential use or industrial applications, the cost of mirror glass plays a significant role in its accessibility and usability in modern design.