In the contemporary landscape of architectural and interior design, the selection of glazing materials extends far beyond mere transparency. Modern construction demands solutions that balance aesthetics, privacy, light diffusion, and structural integrity. Among the myriad options available, types of patterned glass have emerged as a versatile and indispensable component, offering a unique blend of functionality and artistic appeal. This specialized glass is distinguished by its embossed patterns, textures, or designs on one or both surfaces, which are impressed during the manufacturing process. These patterns serve multiple purposes: they diffuse light, obscure vision for privacy without blocking all light, and add a decorative element that can complement or define a space's aesthetic. The demand for high-quality patterned glass for sale has steadily increased, driven by innovative architectural projects, the burgeoning trend of biophilic design, and a renewed emphasis on energy efficiency through optimized natural light distribution. From commercial complexes requiring sophisticated privacy solutions to residential properties seeking unique decorative accents, patterned glass provides an elegant answer. Its inherent ability to soften harsh sunlight while maintaining a bright, airy ambiance makes it particularly attractive for spaces where direct light might be undesirable, or where a certain level of visual obscurity is paramount. Furthermore, its robust nature, coupled with the potential for various treatments like tempering or lamination, ensures its suitability for demanding applications, affirming its status as a premium choice in the B2B sector for discerning specifiers and developers. This comprehensive guide delves into the intricate details of patterned glass, exploring its manufacturing, diverse applications, technical specifications, and market dynamics to provide a holistic understanding for industry professionals. We aim to equip you with the knowledge necessary to make informed decisions when integrating this sophisticated material into your next project, emphasizing its long-term value and aesthetic contribution. The evolution of patterned glass technology has also led to advancements in its thermal and acoustic properties, making it an even more compelling choice for contemporary building envelopes. Its capacity to transform light into a sculptural element while providing functional benefits, such as enhanced privacy or reduced glare, underscores its significant value proposition in the competitive construction materials market.

The market for types of patterned glass is experiencing dynamic growth, propelled by innovations in manufacturing processes and an increasing demand for sustainable and aesthetically pleasing building materials. Current industry trends indicate a strong move towards larger format patterned glass panels, integrating it into smart glass technologies, and exploring new patterns that evoke natural textures or minimalist geometric designs. Architects and designers are increasingly recognizing the versatility of patterned glass beyond traditional bathroom windows or internal partitions; it is now frequently specified for grand entrances, sophisticated office dividers, and even external facades where controlled light entry and visual interest are desired. This expanded application scope is further supported by advancements in glass tempering and lamination, which enhance the safety and security profiles of patterned glass, making it suitable for high-traffic or public areas. Furthermore, the emphasis on indoor air quality and natural light optimization in modern building design positions patterned glass as a key material. It allows for the ingress of ample natural light while mitigating glare and protecting privacy, contributing positively to occupant well-being and reducing reliance on artificial lighting during daylight hours. This dual benefit of light management and privacy makes it an indispensable asset in commercial, residential, and institutional projects alike. The aesthetic versatility, ranging from classic obscure patterns to intricate contemporary designs, allows for bespoke solutions that can significantly enhance a building's character and functionality. Manufacturers are also exploring combinations of patterned glass with low-emissivity (Low-E) coatings and other performance-enhancing layers, pushing the boundaries of what this material can achieve in terms of thermal insulation and solar control, thereby aligning with global efforts towards energy-efficient architecture.

The creation of high-quality types of patterned glass is a testament to sophisticated industrial engineering and precise material science, differing significantly from the production of clear float glass. The fundamental material composition typically involves silica sand (approximately 70-75%), soda ash (sodium carbonate, 12-15%), limestone (calcium carbonate, 8-12%), dolomite, and cullet (recycled glass), along with minor additives to influence color, clarity, and other properties. The primary manufacturing process for patterned glass is the rolling method, which is a continuous casting and calendering technique. This process begins with melting the raw materials in a furnace at extremely high temperatures, often exceeding 1500°C, to form a molten glass 'ribbon'. This viscous, incandescent glass then flows from the melting tank onto a rolling bed. Crucially, as the molten glass passes between two heavy, precisely engineered rollers, one of which has a textured or patterned surface, the desired design is impressed onto the soft glass. The top roller is usually smooth, while the bottom roller carries the inverse of the pattern to be transferred onto the glass surface. For double-sided patterns, both rollers are patterned. This precise mechanical stamping is what gives patterned glass its characteristic textures, ranging from subtle stipples to deep flutes or intricate geometric motifs. After patterning, the glass ribbon enters an annealing lehr, a controlled cooling oven, where it is gradually cooled to relieve internal stresses that could otherwise lead to cracking or instability. This annealing process is vital for the glass's structural integrity and long-term durability, ensuring it meets the stringent requirements for building materials. Upon exiting the lehr, the now solidified and patterned glass ribbon is cut into desired sizes using automated cutters. Each stage of this process, from raw material batching to final cutting, is meticulously monitored to ensure uniformity and quality.

Quality control and adherence to international standards are paramount throughout the production of patterned glass. Manufacturers typically comply with a suite of rigorous inspection standards to ensure product reliability and safety. These include, but are not limited to, ISO 9001 (Quality Management Systems), ASTM C1036 (Standard Specification for Flat Glass), and European Standards like EN 572 (Glass in building – Basic soda-lime silicate glass products). These standards dictate critical parameters such as glass thickness tolerances, optical distortion, pattern uniformity, and surface quality. For specialized applications, additional certifications like ANSI Z97.1 (Safety Glazing Materials) or EN 12150 (Thermally Toughened Safety Glass) may be required if the patterned glass undergoes further processing like tempering. The typical service life of patterned glass, when installed correctly and maintained adequately, can exceed 50 years, often matching the lifespan of the building itself. This longevity is attributed to its chemical stability, resistance to environmental degradation, and the inherent durability imparted by the controlled manufacturing and annealing processes. The applicability of patterned glass spans a wide array of industries beyond residential and commercial architecture. In industrial settings, such as control rooms within petrochemical plants or metallurgical facilities, patterned glass can be used for vision panels where privacy or light diffusion is required without total visual obstruction, reducing glare on monitors while maintaining a bright workspace. In public infrastructure, such as water supply and drainage facilities, it might be employed in administrative areas or service buildings for its aesthetic and light-diffusing properties. The technical advantages in typical application scenarios include enhanced energy efficiency, as the diffused light reduces the need for artificial lighting, and its non-porous surface provides excellent resistance to corrosion from common industrial chemicals and atmospheric pollutants, making it a low-maintenance and durable choice. Its ability to create a soft, even light distribution also contributes to reduced eye strain and improved comfort for building occupants, enhancing productivity in workspaces and the overall user experience in public spaces.

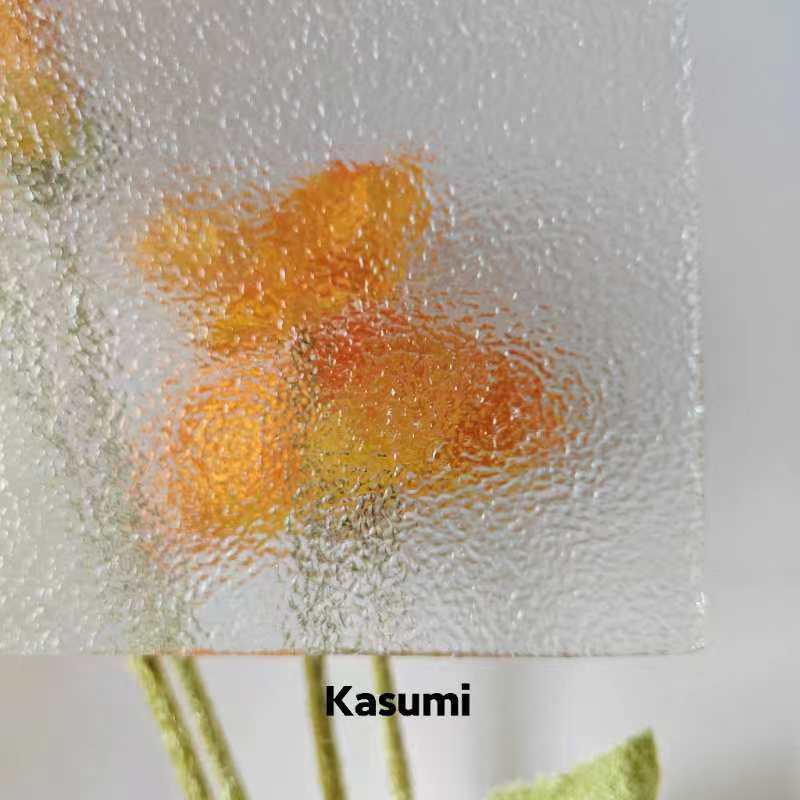

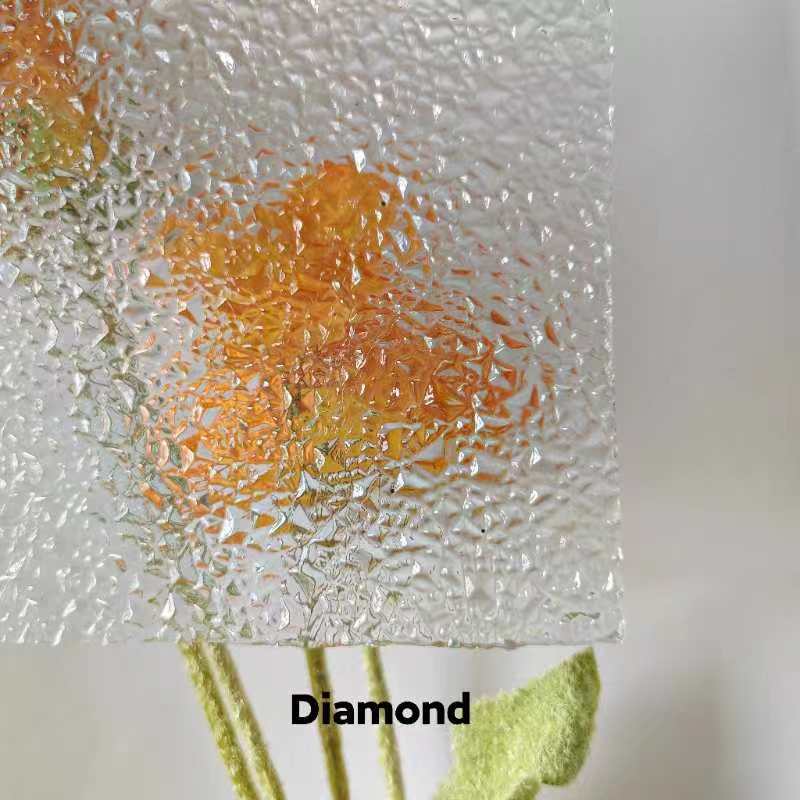

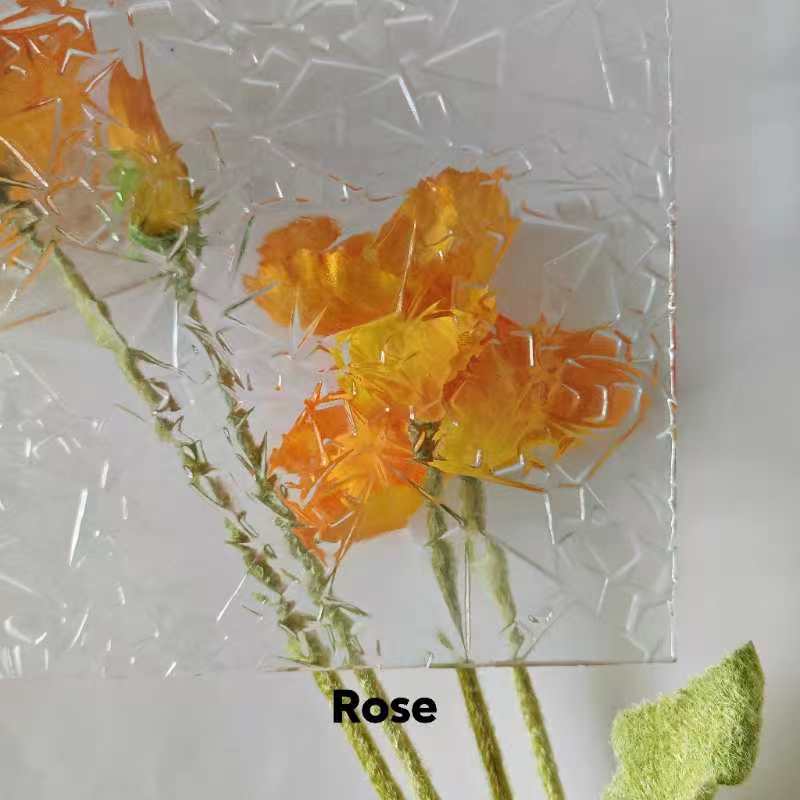

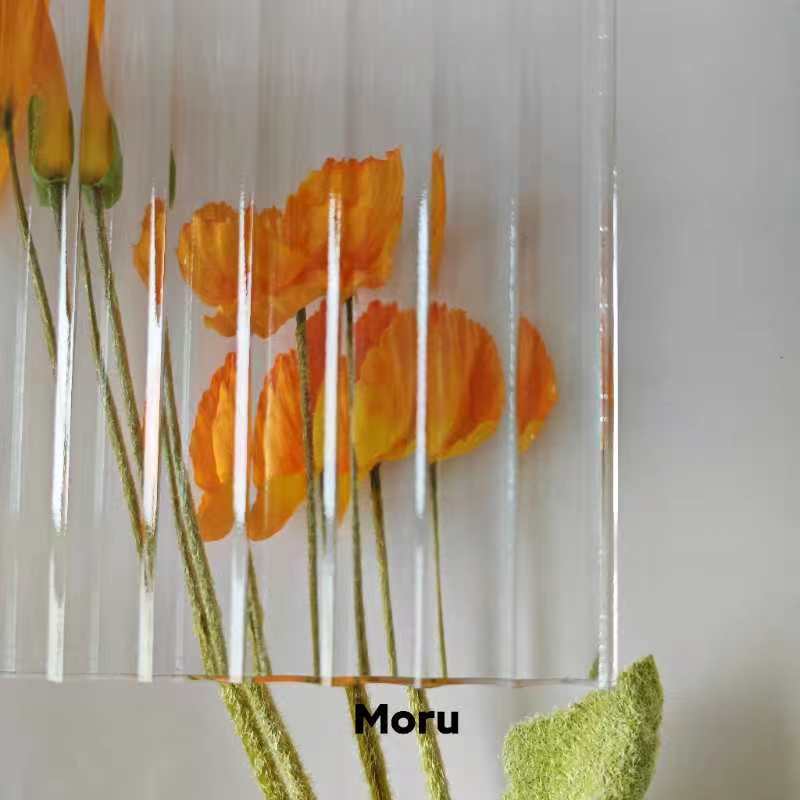

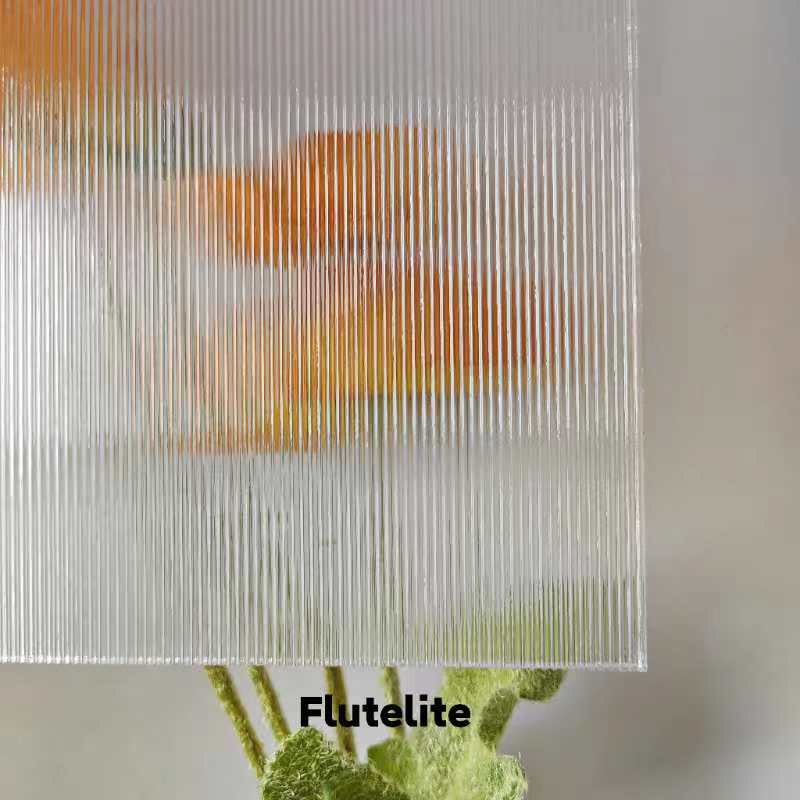

The spectrum of types of patterned glass available on the market is remarkably broad, each pattern offering distinct aesthetic and functional characteristics. Understanding these variations is crucial for specifying the optimal solution for a given architectural or design challenge. Among the most common categories are obscure patterns, which prioritize privacy while allowing significant light transmission. Examples include stippled, reeded, or fluted patterns, which create a distortion effect, making it difficult to see clearly through the glass while still illuminating the space. Fluted or reeded glass, characterized by parallel vertical ridges, is particularly popular for contemporary interiors due to its clean lines and elegant light scattering properties, often specified for office partitions or internal room dividers. Another significant category encompasses floral or geometric patterns, which are more decorative and can range from subtle textures to intricate designs that mimic natural elements or abstract shapes. These are frequently used as decorative patterned glass panels in doors, transoms, or cabinet fronts, adding an artistic touch. Wired patterned glass, while also having a texture, incorporates a wire mesh embedded within the glass during the rolling process. This provides enhanced security and fire resistance, as the wire mesh holds the glass together even if it breaks, preventing shards from falling out and maintaining a barrier against fire spread. This makes it a preferred choice for skylights, fire-rated doors, or industrial applications where safety is paramount. Each pattern has a unique light transmission coefficient and a different level of obscuration, allowing designers to precisely control privacy and light quality. For instance, a heavily textured pattern might offer greater privacy but slightly reduced light transmission compared to a lightly stippled pattern. The thickness of the glass also plays a role in its performance, with thicker glass generally offering better sound insulation and impact resistance, although this also depends on whether it is subsequently tempered or laminated.

The versatility of patterned glass extends to specific applications that leverage its unique characteristics. For residential and commercial properties, patterned glass for doors is a common specification, offering a balance of privacy and natural light in entryways, bathrooms, or interior partitions. When it comes to external applications, selecting patterned glass for external doors demands consideration for weather resistance, security, and thermal performance. Here, thicker glass, potentially laminated or double-glazed patterned units, might be preferred to enhance insulation and impact resistance against external elements. The patterns in external doors not only provide privacy but also diffuse harsh sunlight, preventing excessive heat gain while maintaining a bright interior. Beyond doors, patterned glass is extensively used in shower enclosures, creating elegant and private bathing spaces. Its textured surface minimizes water spotting and soap scum visibility, contributing to easier maintenance. In office environments, patterned glass partitions are increasingly replacing opaque walls, fostering open-plan designs that still offer visual privacy for focused work. The diffused light reduces glare on computer screens and creates a softer, more comfortable lighting environment. Furthermore, patterned glass finds its place in decorative furniture elements, such as cabinet doors, tabletops, and shelving, where it adds texture and visual interest. In retail spaces, it can be used for display cases or shop fronts to create an intriguing visual appeal while subtly obscuring merchandise for an element of surprise or to reduce direct sun exposure on sensitive products. The aesthetic range, from traditional ripple patterns to contemporary geometric designs, allows patterned glass to adapt to various architectural styles, from classic to ultra-modern, making it a highly adaptable material for diverse design palettes.

For B2B specifiers and engineers, understanding the precise technical parameters and performance data of types of patterned glass is critical for optimal material selection and project success. These parameters directly influence the glass's suitability for specific applications, dictating its performance in terms of light transmission, thermal insulation, acoustic dampening, and mechanical strength. Key specifications include thickness, which commonly ranges from 3mm to 12mm, with standard sizes typically available in 4mm, 5mm, and 6mm for most applications, while thicker variants are employed for enhanced structural integrity or when laminated/tempered. Light transmittance, expressed as a percentage, varies significantly based on the pattern's depth, complexity, and the glass's overall opacity. For instance, a lightly patterned glass might offer 85-90% light transmission, while a highly obscure pattern could fall to 60-75%. The U-value (or Ug-value for glass only), which measures thermal transmittance, is crucial for energy-efficient designs; a single pane of patterned glass typically has a U-value ranging from 5.7 to 6.0 W/(m²·K), similar to clear float glass, but this can be significantly improved when incorporated into insulated glass units (IGUs) with inert gas fills and low-emissivity coatings. Sound insulation, measured in decibels (dB), is another important factor, particularly for applications requiring acoustic privacy; standard patterned glass offers basic sound reduction comparable to flat glass of similar thickness, typically around 25-30 dB for a single pane, but can be enhanced through lamination or by being part of an IGU. Breakage resistance, while often not quantified directly for raw patterned glass, is significantly improved when the glass undergoes tempering, transforming it into safety glass that shatters into small, blunt pieces upon impact, or lamination, where a polyvinyl butyral (PVB) interlayer holds shards in place upon breakage.

Further technical details that impact the selection of patterned glass include its chemical durability, which signifies its resistance to weathering, acid, and alkali exposure, making it suitable for various indoor and outdoor environments without significant degradation. The pattern depth and relief can affect its cleanability and overall aesthetic, with deeper textures potentially requiring more effort to clean but offering enhanced visual distortion. Weight per square meter is a critical parameter for structural calculations, especially for large patterned glass panels or overhead glazing; for example, 6mm patterned glass weighs approximately 15 kg/m². Maximum dimensions for single panes of patterned glass are generally limited by manufacturing capabilities but can typically reach sizes up to 2134mm x 3300mm or even larger from specialized manufacturers, allowing for expansive architectural applications. These parameters collectively inform how patterned glass performs under various environmental conditions and user requirements. For instance, in an application like patterned glass for external doors, a specifier would prioritize higher breakage resistance (tempered/laminated), improved U-value (IGU), and adequate privacy (pattern choice). For interior uses like shower screens or room dividers, privacy levels, ease of cleaning, and decorative appeal become more prominent. The table below provides a concise overview of typical technical parameters, offering a quick reference for comparison across different types of patterned glass. These specifications highlight the versatility and adaptability of patterned glass, enabling its integration into complex and high-performance building systems while contributing to both functional efficacy and design excellence.

The adaptability and aesthetic appeal of types of patterned glass allow for its integration into an extensive range of applications across diverse industries, extending far beyond conventional windows and doors. In architectural contexts, patterned glass is increasingly specified for interior partitions and room dividers in both commercial and residential settings. This facilitates open-plan designs that still respect the need for visual privacy and quiet zones. For instance, in corporate offices, conference rooms or executive suites can utilize patterned glass panels to maintain an open feel while preventing visual distractions and offering a degree of acoustic separation. The diffused light creates a pleasant working environment, reducing glare on screens and fostering a sense of spaciousness. In healthcare facilities, patterned glass can be used in waiting areas or consulting rooms to manage patient privacy subtly. For residential spaces, patterned glass is highly sought after for shower screens, where its textured surface provides essential privacy, masks water spots, and introduces a sophisticated design element that elevates the bathroom aesthetic. It is also popular for kitchen cabinet inserts, internal door lites, and even stair railings, adding unique texture and light effects. The use of patterned glass for sale in furniture design, such as table tops, shelving, and display units, highlights its role as a decorative and functional material that can transform ordinary objects into focal points. Beyond standard applications, patterned glass is also finding niche uses.

In industrial and public sector domains, the strategic application of patterned glass provides both functional benefits and improved environmental conditions. While "petrochemical," "metallurgy," or "water supply/drainage" industries might typically employ more robust, specialized glass for process viewing, patterned glass can find its place in the administrative, control room, or common areas of these facilities where light management, privacy, and aesthetics are desired. For example, in the offices adjacent to a metallurgical plant, patterned glass panels could be used for office partitions to control visual access to work areas while allowing natural light to penetrate deeply into the floor plan, enhancing worker comfort and potentially reducing energy consumption for lighting. In water treatment plants, patterned glass might be used in laboratory or control room windows to diffuse bright sunlight and mitigate glare, which can be particularly intense in open industrial environments, thereby improving visibility for technical staff. Its inherent chemical resistance makes it suitable for environments where exposure to certain airborne chemicals or dust might occur, ensuring long-term clarity and structural integrity compared to other materials. The advantages of patterned glass in these typical application scenarios are manifold: Firstly, enhanced energy efficiency is achieved through optimized natural light diffusion. By scattering harsh direct sunlight, patterned glass reduces solar heat gain, lessening the load on HVAC systems in warmer climates, while simultaneously providing ample ambient light, thereby reducing the reliance on artificial lighting during daylight hours. This contributes to significant operational cost savings and aligns with green building initiatives. Secondly, its excellent resistance to corrosion, due to the stable chemical composition of glass, makes it a durable choice in environments where moisture, humidity, or certain chemical exposures are a concern. This feature ensures a longer lifespan and lower maintenance requirements compared to less resilient materials. Lastly, the inherent privacy benefits, without sacrificing natural light, improve the quality of internal environments, making spaces more comfortable and functional for their occupants, whether in a high-tech corporate setting or a public service building.

The contemporary market for types of patterned glass increasingly emphasizes customization to meet the unique aesthetic and functional demands of modern architectural projects. Manufacturers are now capable of offering extensive customization options that extend beyond mere standard patterns and thicknesses. Clients can specify bespoke patterns, often achieved through custom roller designs, allowing for brand-specific motifs or highly unique visual textures that align with a building's overall design language. Furthermore, patterned glass can be produced in a wide range of sizes, from small decorative inserts to large-format patterned glass panels, ensuring seamless integration into various structural frameworks. Beyond dimension and pattern, color tinting is another customization avenue, where the molten glass can be imbued with various pigments to achieve specific hues, enhancing the decorative effect or complementing a color scheme. Post-production processing adds another layer of versatility: patterned glass can be tempered for increased safety and impact resistance, making it suitable for high-traffic areas or applications like patterned glass for doors (especially patterned glass for external doors) where safety glazing standards are critical. Lamination, involving bonding two or more glass panes with a plastic interlayer (PVB or SGP), further enhances safety by holding shattered fragments in place upon impact and offers superior acoustic performance and UV protection. Additionally, surface treatments such as sandblasting or acid-etching can be applied to parts of the patterned glass to create even more intricate designs or gradients of opacity, providing designers with unparalleled creative freedom.

When selecting a supplier for patterned glass, a thorough comparison of manufacturers is essential to ensure quality, reliability, and technical compliance. Key criteria for evaluation include the manufacturer's adherence to international quality management systems, most notably ISO 9001, which signifies a commitment to consistent product quality and customer satisfaction. Certifications like CE marking (for European markets) and compliance with specific national standards such as ANSI Z97.1 (for safety glazing in North America) or EN 12150 (for toughened glass) are non-negotiable indicators of product safety and performance. A reputable manufacturer will also demonstrate robust research and development capabilities, indicating an ongoing commitment to innovation in patterned glass technologies, patterns, and processing techniques. This R&D strength often translates into a wider range of standard patterns, greater customization potential, and enhanced performance attributes. Lead times and delivery capabilities are crucial for project scheduling, especially for large-scale or time-sensitive constructions; a reliable manufacturer will have efficient logistics and production schedules to meet deadlines. Furthermore, the breadth and quality of after-sales support, including technical assistance, warranty terms, and dispute resolution mechanisms, reflect a manufacturer's commitment to long-term client relationships and product reliability. Manufacturers with a long service history and extensive portfolio of successful projects, coupled with transparent documentation of their testing data and authoritative third-party certifications (e.g., from recognized testing laboratories), instill confidence and affirm their authoritativeness in the industry. For instance, testing data for light transmission, U-values, and impact resistance should be readily available and verifiable. Partnerships with leading architectural firms or large-scale developers also serve as indicators of a manufacturer's standing and capabilities within the B2B sector. These elements collectively form a comprehensive framework for assessing a manufacturer's expertise, experience, authoritativeness, and trustworthiness, crucial pillars for any B2B purchasing decision.

The practical application of types of patterned glass is best illustrated through real-world case studies that highlight its transformative potential. Consider a contemporary commercial office building aiming for a vibrant, collaborative workspace while ensuring acoustic and visual privacy for individual departments. Here, large patterned glass panels with a fluted design could be specified for interior office partitions and meeting room enclosures. This choice allows natural light to permeate deep into the building's core, creating a bright and open atmosphere, while the fluted pattern subtly obscures direct views, preventing distractions and maintaining a sense of separation. The diffused light also contributes to reduced glare on computer screens, enhancing employee comfort and productivity. Another compelling example involves a high-end residential renovation where an architect sought to infuse a traditional home with modern elegance. For the main entrance, a bespoke patterned glass for external doors, featuring a custom geometric design, was installed. This not only provided an immediate aesthetic upgrade but also ensured privacy for the homeowners, diffusing views from the street while allowing ample natural light to illuminate the foyer. Similarly, in a public library, patterned glass was utilized for study carrels and quiet reading nooks. The chosen pattern diffused the overhead lighting and external daylight, creating a soft, glare-free environment conducive to reading, while also providing a sense of seclusion for individuals without making the space feel entirely enclosed. These examples underscore how patterned glass balances functional requirements with significant aesthetic contributions, adapting to diverse scales and design philosophies across various sectors.

Looking ahead, the market for patterned glass is poised for continued innovation and expanded adoption, driven by evolving architectural trends and technological advancements. One significant trend is the increasing emphasis on sustainability in construction. Patterned glass contributes to this by optimizing natural light, thereby reducing energy consumption for artificial lighting and potentially lowering cooling loads by diffusing solar heat gain. The integration of patterned glass with smart glass technologies, such as switchable privacy glass that can incorporate patterned textures, represents a frontier of innovation, offering dynamic control over light and privacy. This could lead to applications where the patterned effect can be electronically varied. Furthermore, there is a growing demand for larger patterned glass panels to create seamless, impactful architectural statements, pushing the boundaries of manufacturing capabilities. The resurgence of retro and biophilic design trends also fuels the demand for patterned glass, as its inherent textures and light-diffusing properties resonate with designs that seek to connect interiors with nature or evoke a sense of timeless craftsmanship. The increasing awareness of occupant well-being in building design also positions patterned glass favorably. By providing visual comfort, reducing glare, and enhancing privacy without sacrificing natural light, it contributes to healthier and more productive environments. The future outlook for patterned glass for sale is bright, with ongoing research into new patterning techniques, surface coatings for enhanced performance (e.g., self-cleaning or anti-microbial properties), and its integration into complex facade systems. As architects and designers continue to seek materials that offer both high performance and distinctive aesthetic qualities, patterned glass will remain a vital and evolving component in the advanced building materials landscape, securing its relevance in future construction and renovation projects worldwide.

Building trust and ensuring comprehensive customer support are foundational pillars for any successful B2B relationship, especially in specialized product categories like types of patterned glass. We understand that selecting the right glass for your project involves technical considerations, logistical planning, and financial commitments. To address common inquiries and provide transparency, we've compiled a Frequently Asked Questions (FAQ) section. Typical questions often revolve around pattern availability, specific thickness options, whether a particular pattern can be tempered or laminated, and suitability for various environments such as high-humidity areas or external facades. For example, a common query is: "Can patterned glass for doors be used in a bathroom shower enclosure?" The answer depends on pattern and whether it's tempered for safety, confirming its compliance with local building codes. Another frequent question pertains to lead times: "What is the typical delivery cycle for custom patterned glass panels?" Our standard lead time for stock patterned glass is typically 2-4 weeks, while custom orders or those requiring specific post-processing (e.g., tempering, lamination) may range from 4-8 weeks, depending on complexity and volume. We pride ourselves on clear communication regarding project timelines and provide realistic estimates from the outset. Furthermore, our commitment to quality is reinforced by a robust warranty policy. All our patterned glass products come with a comprehensive 10-year warranty against manufacturing defects and material degradation under normal use and proper installation. This warranty covers issues such as significant pattern distortion, material discoloration (unless specified as tinted), or premature delamination for laminated units. Specific terms and conditions are provided with each quotation and delivery. This commitment underscores our confidence in the durability and performance of our products.

Beyond initial product acquisition, exceptional customer support ensures long-term satisfaction and successful project outcomes when dealing with diverse types of patterned glass. Our dedicated technical support team comprises experienced glass engineers and product specialists available to assist with every phase of your project. This includes pre-sales consultation, where we provide expert guidance on pattern selection, thickness recommendations, and advise on necessary post-processing for compliance with specific safety or performance standards (e.g., for patterned glass for external doors). During the specification phase, we offer detailed product data sheets, CAD drawings, and samples to facilitate informed decision-making. For installation, our team can provide best practice guidelines and troubleshoot potential issues. After-sales support extends to addressing any concerns post-delivery or installation, ensuring complete client satisfaction. We also offer maintenance recommendations for different patterned glass types to preserve their aesthetic and functional integrity over their extended lifespan. Our commitment to transparent communication, timely delivery, and unwavering support builds enduring partnerships, establishing us as a reliable and authoritative supplier of high-quality patterned glass solutions for any scale of B2B project. We understand that complex projects require not just superior products but also a dependable partner who can provide consistent expertise and support throughout the project lifecycle.

The information presented herein is underpinned by established industry practices, rigorous scientific principles, and insights from leading publications in materials science and architectural engineering. For further authoritative context and in-depth technical specifications related to types of patterned glass and general glazing principles, we recommend consulting the following resources:

These organizations and publications serve as authoritative sources within the global glass and construction industries, offering peer-reviewed research, standardized testing methodologies, and expert consensus on material properties and applications. Consulting these references ensures that architectural designs and material specifications are based on the most current and reliable information available.