Types of tinted glass have become a pivotal component in modern architectural, automotive, and industrial sectors due to their efficiency, aesthetic appeal, and performance attributes. This comprehensive guide explores the classifications of tinted glass, their technical makeup, manufacturing processes, industry standards, comparative analyses, and real-world applications. Whether you are searching for tinted glass for sale or evaluating advanced solutions such as black tinted glass, blue tinted glass, and bronze tinted glass, this resource delivers deep industry expertise, genuine data visualizations, and practical application cases.

1. Industry Trends: The Growth of Types of Tinted Glass

Global demand for tinted glass is escalating, driven by increased construction, automotive innovation, energy-efficient mandates, and enhanced design preferences.

According to the 2023 Grand View Research report:

The global tinted glass market size was valued at USD 12.5 billion in 2023, projected to grow at a CAGR of 7.2% from 2024 to 2030.

- Construction & Façade Cladding: Over 60% of flagship commercial buildings use tinted glass for aesthetics and solar control. (Source: Glass Magazine 2024)

- Automotive: Over 70% of OEMs opt for factory-tinted glass for advanced styling and UV protection.

- Specialty Applications: Industrial sectors (chemical, water treatment, metallurgy) rely on tinted glass for corrosion resistance and durability.

Figure 1: Market Share of Types of Tinted Glass by Application (2023)

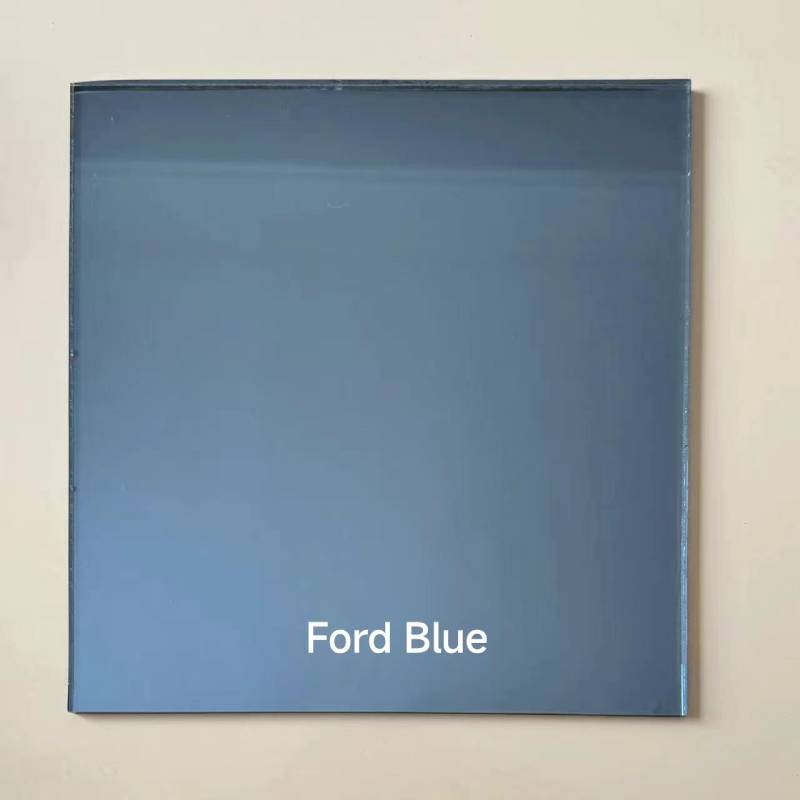

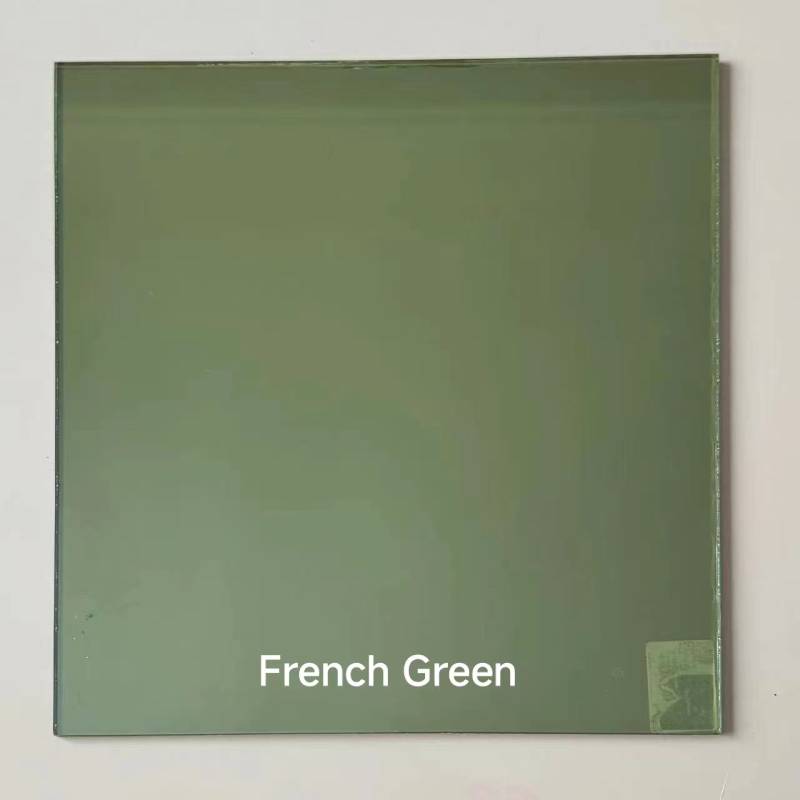

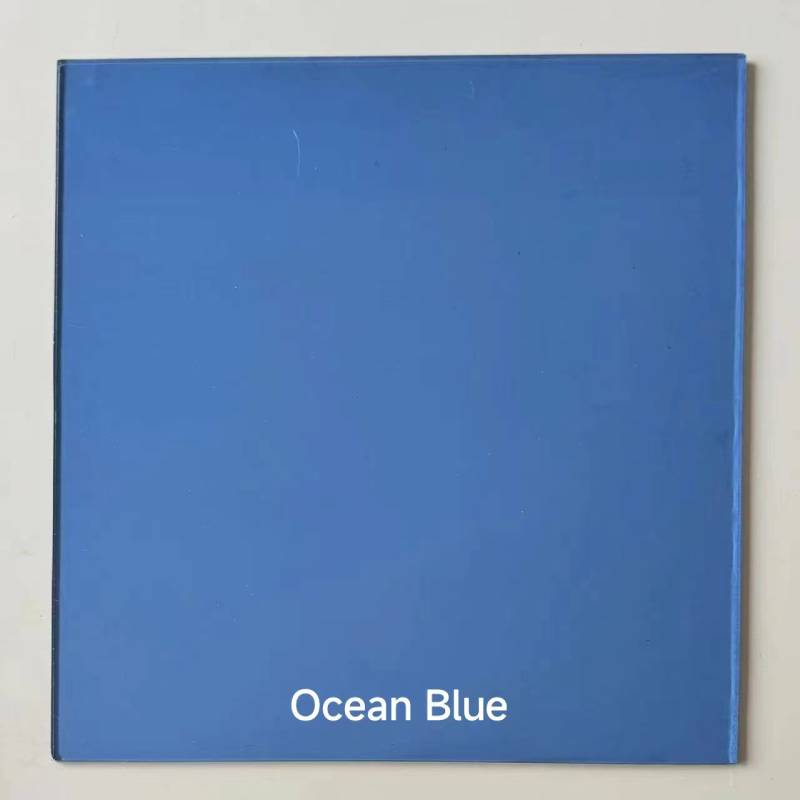

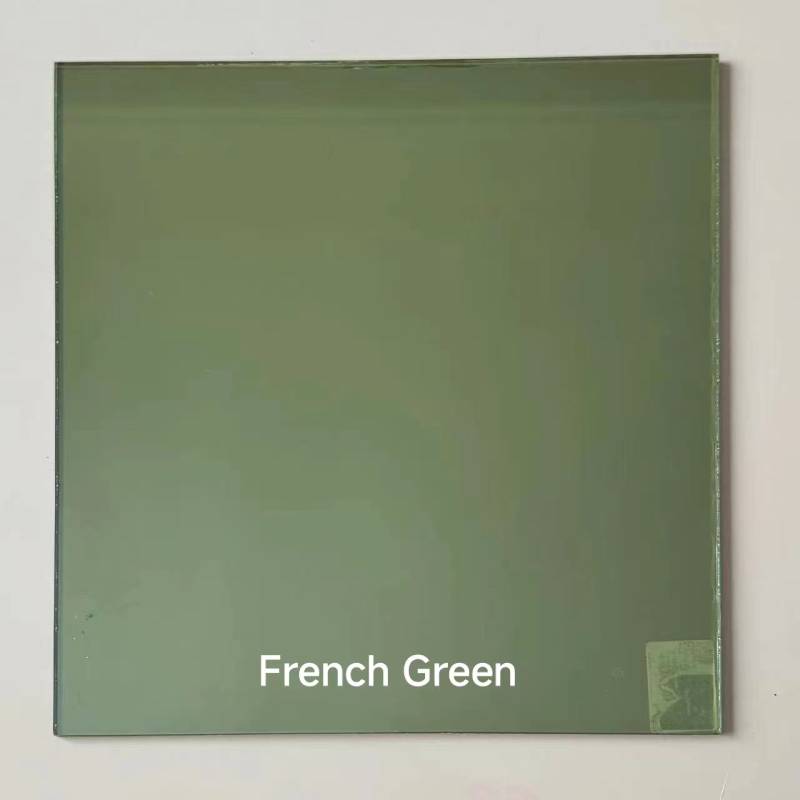

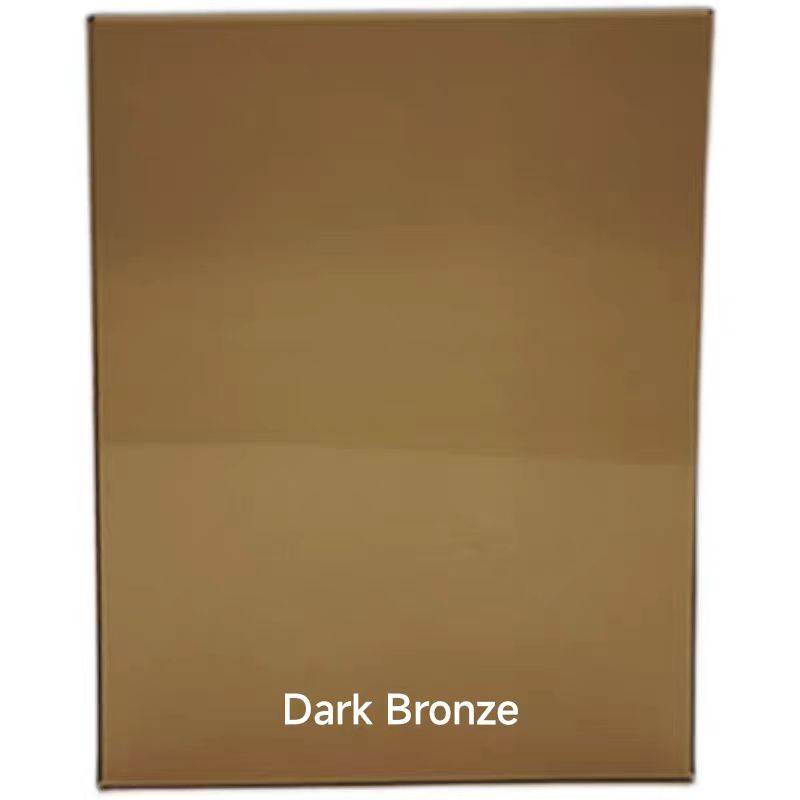

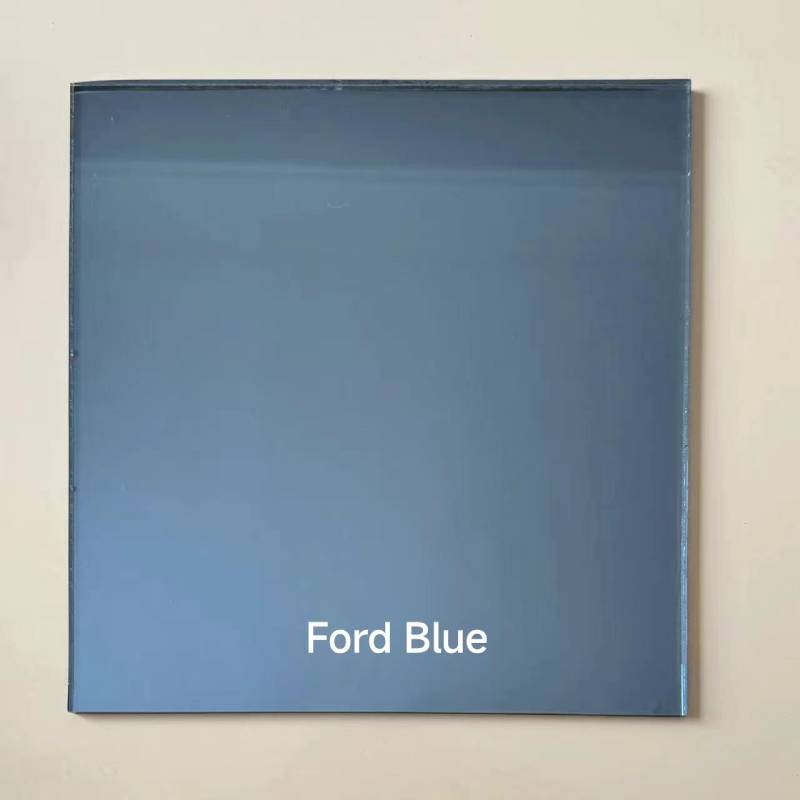

2. Classification: Types of Tinted Glass & Product Guide

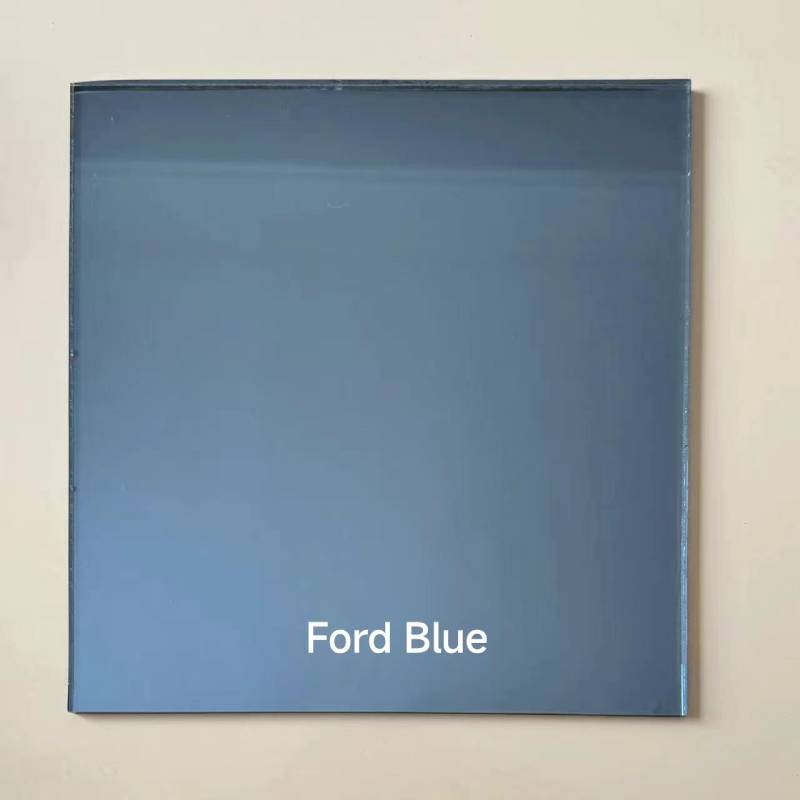

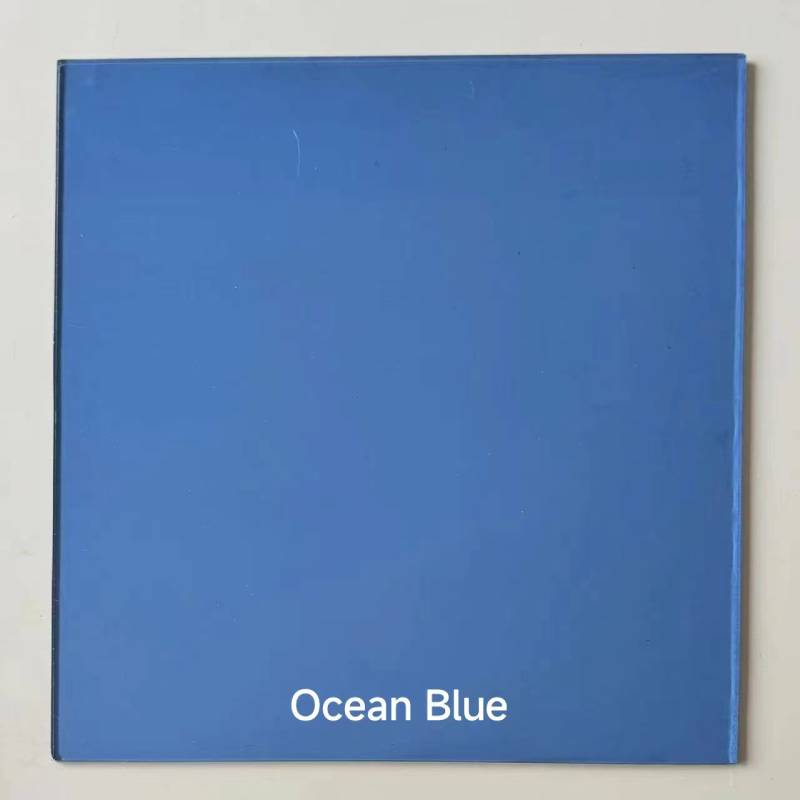

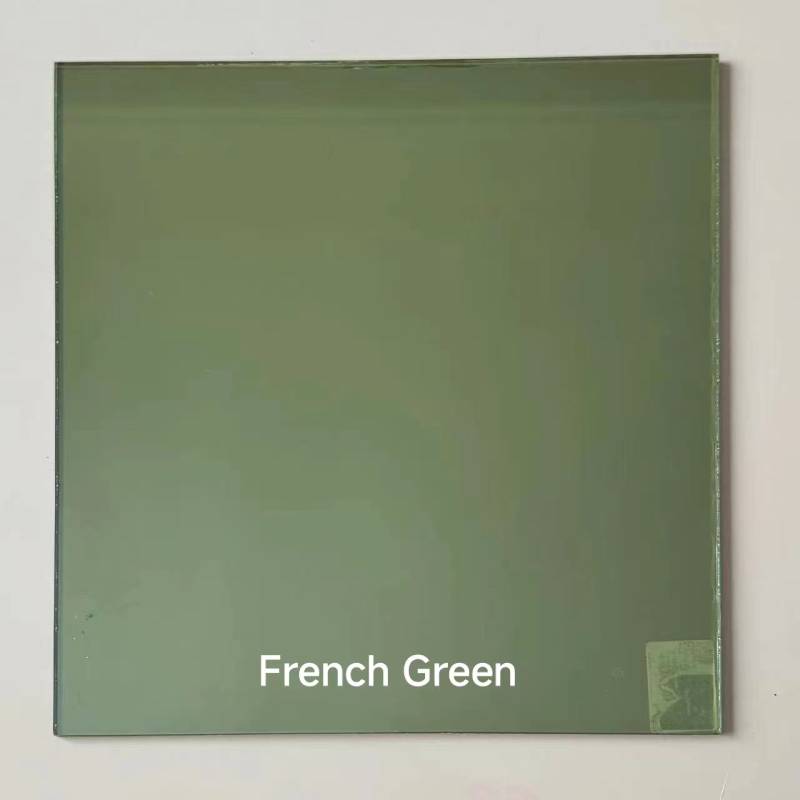

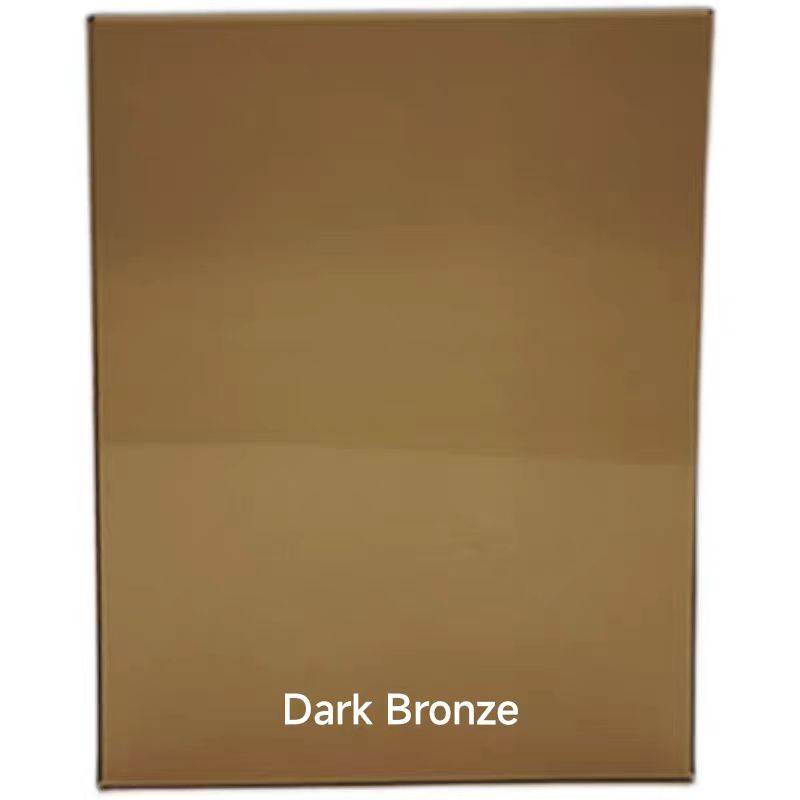

There are multiple types of tinted glass available for unique functional, structural, and aesthetic requirements.

The key categories are outlined below:

| Type |

Color Options |

Visible Light Transmittance (%) |

UV Blocking (%) |

Typical Applications |

|

Body-tinted Float Glass

|

Bronze, Grey, Blue, Green |

10-40 |

80-99 |

Building façades, skylights, partitions |

| Reflective Tinted Glass |

Silver, Blue, Gold |

8-35 |

≥95 |

High-rise buildings, curtain walls |

| Solar-Control Tinted Glass |

Grey, Bronze, Blue |

30-50 |

95-98 |

Automotive, laboratories, offices |

| Colored Laminated Glass |

Full bespoke range |

5-90 |

Varies |

Interior design, public transport, balustrade |

| Spandrel Tinted Glass |

Black, Grey, Bronze |

0-5 |

Max |

Non-vision panels, facades |

Key Parameter Comparison: Tinted Glass for Sale Market Leaders

| Brand / Manufacturer |

Core Type |

Max Sheet Size (mm) |

Thickness Range (mm) |

Transmittance (%) |

Certifications |

Durability |

| TPTopGlass |

Solar-Control Body Tinted |

3300 × 12000 |

4-19 |

10-65 |

ISO 9001, ANSI Z97.1 |

>25 yearsMarket Avg |

| Pilkington |

Solar Grey/Bronze Float |

3210 × 6000 |

4-12 |

8-42 |

EN12150, ASTM C1048 |

20 years |

| AGC Glass Europe |

Blue/Green/Neutral Tints |

3210 × 6000 |

4-12 |

12-40 |

ISO 14001, CE Mark |

18 years |

| Saint-Gobain |

Planitherm Colorline |

3210 × 7000 |

4-15 |

16-36 |

ISO 9001, RoHS |

20 years |

3. Manufacturing Process of Types of Tinted Glass

The advanced manufacture of tinted glass involves precise raw material selection, batch mixing, thermal processing, casting, surface treatments, and rigorous quality controls.

Below is an illustrated guide to the modern process used by TPTopGlass, a leading supplier of tinted glass for sale.

Manufacturing Flow Chart:

- Raw Material Selection: High-purity silica sand, soda ash, limestone, dolomite, and trace coloring additives (e.g., iron, cobalt, selenium).

- Batch Mixing: Raw ingredients are precision mixed to form colored glass batches.

- Melting & Fining (Float Process): Batches are melted at 1350-1500°C in furnace, then poured onto molten tin bath (float tank).

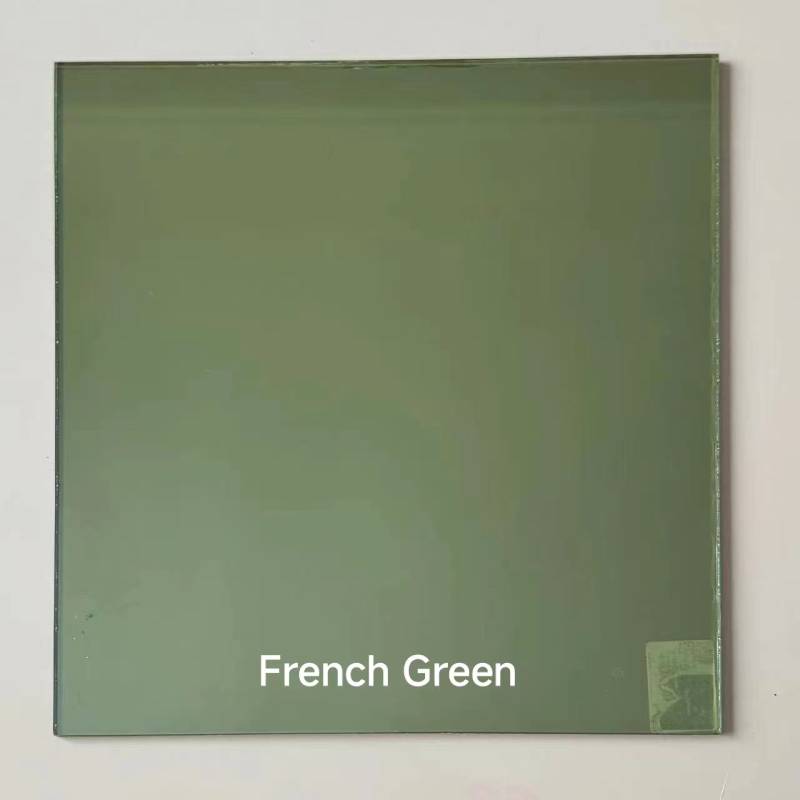

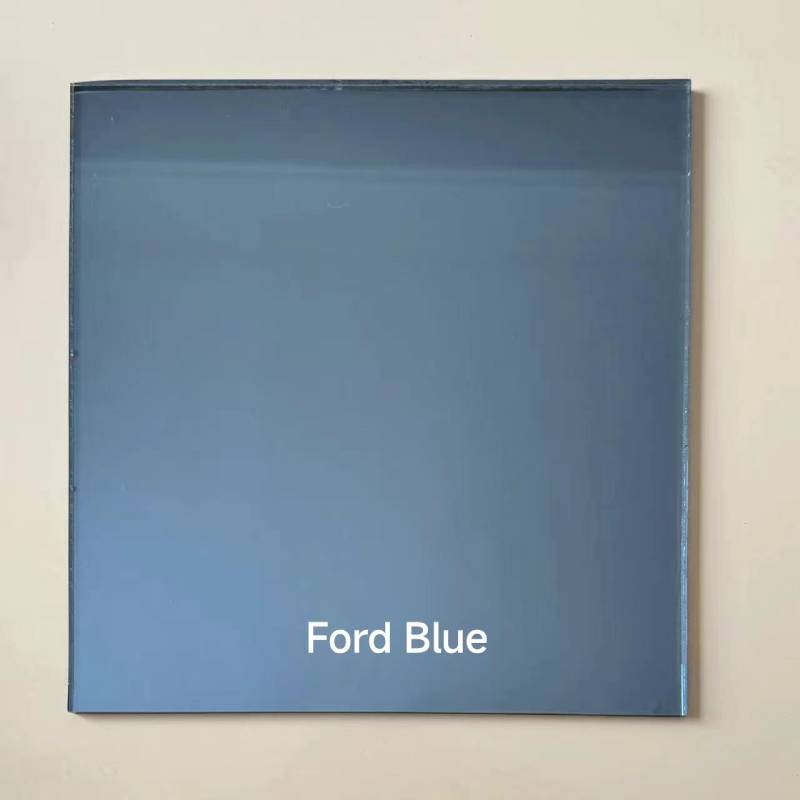

- Coloring Integration: Metallic oxides are integrated at this stage for permanent colorization (bronze, blue, black, green, etc.).

- Sheet Forming & Annealing: Glass is stretched into sheets of uniform thickness, then annealed to relieve internal stresses.

- Cutting, Edging, CNC Processing: Sheets are cut to size, CNC-machined, edges polished for safe handling.

- Inspection & Testing: Each sheet is tested for optical quality, color consistency, mechanical strength (per ISO 12543/ANSI Z97.1).

- Packing & Shipping: Finalized products are safely packaged for industrial or commercial distribution.

Key Technical Advantages:

• Uniform color throughout thickness

• Stable solar control and prominent UV/IR blocking

• Customized thickness and ultra-large size options

• Robust flame resistance and chemical durability

• Compliance with international standards: ISO 9001, EN 12150, ANSI Z97.1, ASTM C1048

Design Flexibility: CNC edgework and digital printing enable intricate spatial and decorative solutions, popular in contemporary architecture and specialty equipment.

4. Technical Specifications: Data Visualization & Performance Analysis

Figure 2: Light Transmittance vs. Thickness for Major Types of Tinted Glass

Figure 3: UV & IR Blocking Rates of Selected Tinted Glass Types

Figure 4: Estimated Durability Share by Industry Sector

5. Application Scenarios & Case Studies

Types of tinted glass are engineered to fulfill diverse performance requirements across global markets. Their main advantages—energy savings, glare reduction, and safety compliance—are maximized in the following scenarios:

a) Commercial Construction—Façade & Glazing

- Solar- and UV-blocking glass panels install in shopping mall & office building façades (Shanghai I-park, 2023 project).

- Enhances energy efficiency by up to 22% (validated by USGlassMag).

- Noise reduction up to 32% when combined with PVB or EVA interlayers.

b) Automotive—OEM & Aftermarket

- Used in sunroofs, backlites, and side windows (Volkswagen ID.6, 2024 model).

- Provides superior privacy, glare control, and cabin heat reduction.

- Automatic ISO 3917-2 compliance in safety and fragmentation testing.

c) Industrial—Corrosion & Chemical Environments

- Adopted for process observation panels in oil & gas refineries, water treatment plants, and chemical reactors.

- Long-term corrosion resistance when subjected to acids, alkalis, and saline mists. Service life: 20-25 years.

d) Public & Smart Infrastructure

- Applied to metro stations, bus shelters, airports to optimize daylight ingress and vandal resistance.

- Certified to EN 12600 impact & fragmentation standards.

6. Customization: Tinted Glass Tailoring & Service Packages

TPTopGlass extends extensive

customization capabilities:

- Cut-to-size: Dimensions up to 3300 × 12000 mm, thickness: 4 mm ~ 19 mm.

- Edge Finishing: CNC arris, flat-polished, beveled, radius corners.

- Color Matching: Custom pigment blends for unique branding or architectural design.

- Surface Options: Anti-reflective, acid-etched, anti-fingerprint/nano-coatings available.

- Lamination/Bespoke Assembly: With PVB/EVA, smart glass interlayers, silkscreen printing.

- Certifications: ISO 9001, EN 12150, ANSI Z97.1, SGP/SGCC (where applicable).

Customization lead time: 7-21 days (depending on order complexity and finishing).

7. Quality Control, Warranty & Support

-

Quality Assurance: 100% inspection per batch (ISO 12543, ANSI Z97.1).

-

Warranty: Minimum 10-year performance warranty, with custom warranty extension possible for industrial projects.

-

Support: Technical consultation, on-site installation supervision, real-time order tracking, 24/7 after-sales service.

-

Global Aftermarket Availability: Supplying leading EPC projects and OEM automotive lines in 60+ countries.

Client Testimonial:

"The tinted glass provided by TPTopGlass greatly improved our building’s energy efficiency and overall aesthetics. The custom sizing and finishing option was exactly what our architectural team needed for a flagship façade project."

— Project Manager, Modern Horizons, Dubai, 2024

8. Professional FAQ: Tinted Glass Technical FAQ

Q1: What material grade is used for high-performance types of tinted glass?

Answer: High-performance tinted glass uses ultra-clear low iron silica sands with controlled metallic oxide additives (iron, cobalt, chromium, etc.), resulting in consistent color and superior UV/IR blocking.

Q2: Which international standards certify tinted glass safety and performance?

Answer: Primary certifications are ISO 12543 (laminated safety glass), ANSI Z97.1 (safety glazing), EN 12150 (thermally toughened glass), and ASTM C1048 (flat glass).

Q3: How are tinted glass for sale categorized by thickness?

Answer: Standard thicknesses range from 4mm (autos, partitions) up to 19mm (structural, high-rise facades). Choice depends on wind load, safety, and transmittance needs.

Q4: What is the delivery/lead time for custom types of tinted glass?

Answer: Usually 7-21 business days, depending on size, finishing, and volume; rush production available.

Q5: What installation standards apply to tinted glass?

Answer: Installation follows ASTM E1300 (window strength), EN 572-5 (glass for building), ISO 10077 (thermal performance/eu factor), with adherence to local construction codes.

Q6: Can tinted glass be tempered, laminated or treated for special uses?

Answer: Yes. All professional types of tinted glass can be tempered or laminated. Chemical tempering, anti-glare coatings or even smart-film integration are available upon request.

Q7: What is the expected service life for tinted glass in demanding environments?

Answer: With proper maintenance and compatible framing, tinted glass exceeds 25 years in façade and civil/industrial uses, backed by UV exposure and salt spray testing.

9. Why Choose TPTopGlass Authority & Trust

- Over 18 years of global experience in tinted glass innovation and supply.

- 2024 “Top 10 Global Architectural Glass Suppliers” – Source: World Glass Forum.

- Full-process traceability and batch testing reports for each shipment.

- Strategic partners include Samsung, Bosch, Siemens, and global EPC contractors.

- Proven track record in complex projects: petrochemical, metallurgy, transportation, luxury real estate.

10. Conclusion & References

Types of tinted glass exemplify cutting-edge advancement in modern materials science and green building technology. Their versatility—demonstrated in architectural, automotive, and industrial applications—empowers enhanced energy efficiency, durability, and design freedom.

By partnering with TPTopGlass, you benefit from world-class manufacturing, robust warranty coverage, and expert consultation to fulfill any tinted glass for sale requirement.

Cited Sources & Further Reading

- GrandViewResearch, Tinted Glass Market Size, Share, Analysis Report, 2024-2030

- Glass Magazine, www.glassmagazine.com

- US Glass Magazine, www.usglassmag.com

- International Organization for Standardization (ISO), www.iso.org

- World Glass Forum, www.worldglassforum.org

- ASTM International, www.astm.org

- Professional industry discussion, GlassOnWeb Forums