The Wonders of Float Annealed Glass A Comprehensive Overview

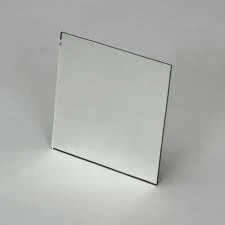

Float annealed glass is a remarkable product that has revolutionized the glass industry, known for its clarity, uniform thickness, and stunning aesthetic appeal. Its journey from raw materials to finished product is a fascinating process that combines science and artistry, making it an essential material in construction, architecture, and interior design.

The Manufacturing Process

The production of float annealed glass begins with the careful selection of raw materials, primarily silica sand, soda ash, and limestone. These components are melted together in a furnace at high temperatures exceeding 1,700 degrees Celsius. The molten glass is then poured onto a flat surface of molten tin, where it spreads out evenly. This unique method, known as the float process, allows for the creation of glass sheets that are incredibly flat and smooth.

Once the glass has been formed, it must undergo a crucial annealing process. Annealing is a controlled cooling process that reduces internal stresses within the glass produced during the rapid cooling after being formed. The glass sheets are slowly cooled in a lehr, ensuring they achieve optimum strength and durability. This process not only enhances the glass’s performance but also minimizes defects, resulting in a high-quality product.

Properties and Benefits

Float annealed glass is characterized by its exceptional optical clarity and uniform thickness, making it ideal for a variety of applications. The glass is transparent, allowing for natural light to enter spaces while providing an unobstructed view. Its consistency in thickness leads to predictable performance in applications involving insulation and energy efficiency.

Another key benefit of float annealed glass is its versatility. It can be easily cut, polished, and processed further into different forms, such as laminated or tempered glass. This adaptability allows architects and designers to explore a wide range of creative possibilities in their projects.

Moreover, float annealed glass is known for its safety features

. While it does not possess the same impact resistance as tempered glass, it can be laminated with safety interlayers to improve its strength, making it a popular choice for windows and facades in both commercial and residential buildings.Applications in Modern Architecture

The use of float annealed glass in modern architecture is ubiquitous. It creates stunning facades that reflect the surrounding environment, blending seamlessly with nature. In office buildings, large glass panels enhance the aesthetic appeal while maximizing natural lighting, which is increasingly recognized for its positive effects on productivity and well-being.

In residential projects, float annealed glass is often employed in windows and glass doors to create a seamless indoor-outdoor experience. The unobtrusive transparency allows homeowners to enjoy unobstructed views and enhances the feeling of space within their homes.

Additionally, the energy efficiency of float annealed glass can be further improved through coatings that reflect heat, making it an excellent choice for environmentally-conscious designs. Architects are increasingly utilizing these energy-efficient solutions to meet stricter building codes and to reduce the overall carbon footprint of their projects.

Conclusion

In conclusion, float annealed glass is not only a visually stunning material but also a testament to the intersection of technology and design in the glass manufacturing industry. Its unique properties and adaptability make it a favorite among architects and designers, facilitating the creation of modern, energy-efficient spaces. As the demand for sustainable and innovative building materials continues to rise, float annealed glass will undoubtedly remain at the forefront of architectural advancements. It represents a perfect blend of functionality and beauty, setting the standard for glass products in various applications.