The Float Glass Manufacturing Industry A Glimpse into the Processes and Key Players

Float glass, a popular type of flat glass, is ubiquitous in architecture, automotive, and various industrial applications. Its distinctive properties derive from a unique production method that ensures smooth, uniform surfaces ideal for numerous uses. This article explores the float glass manufacturing process, the key players in the industry, and the future outlook for this essential material.

The Float Glass Process

The float glass manufacturing process, developed in the 1950s by Sir Alastair Pilkington, is characterized by its simplicity and efficiency. The fundamental elements involved in this method include raw materials such as silica sand, soda ash, and limestone, which are combined and melted in a furnace at temperatures exceeding 1,700 degrees Celsius.

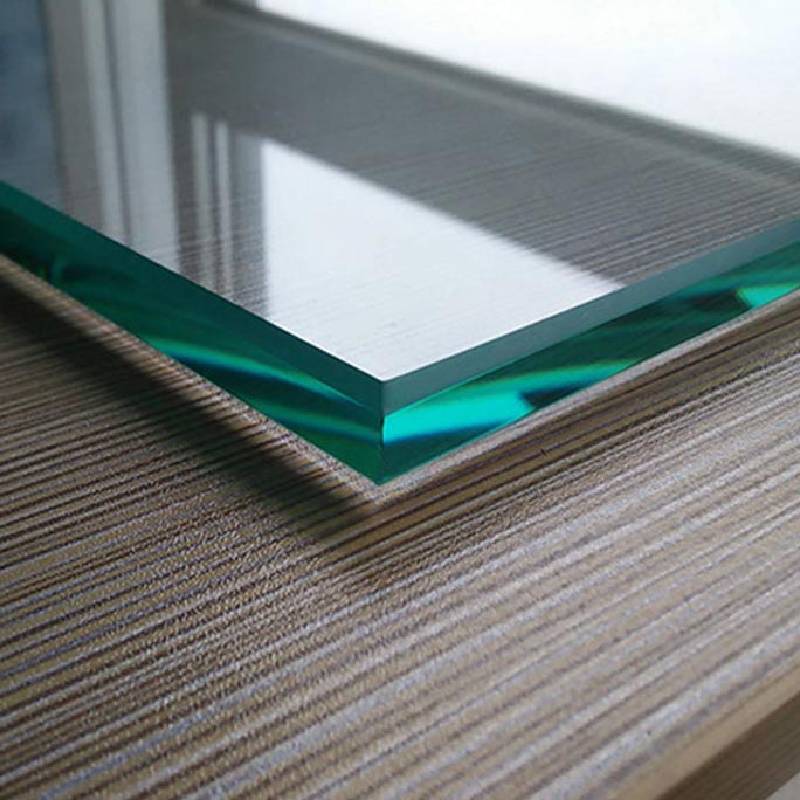

Once melted, the molten glass is poured onto a pool of molten tin. The lighter glass floats on the tin, creating a smooth and flat surface as it spreads. This floating process eliminates the need for later grinding and polishing, producing large sheets of glass with exceptional clarity and uniform thickness. The thickness of the glass can be controlled by adjusting the size of the molten glass mass, which is then cooled slowly to avoid internal stresses.

After the float process, the glass is cooled in a controlled environment in a process known as annealing. This step is crucial for ensuring the glass maintains its structural integrity. Once sufficiently cooled, the glass sheets are cut to size and may undergo further processing, such as coating for enhanced features like reflectivity, UV protection, or increased durability.

Key Manufacturers in the Industry

Several major companies dominate the global float glass manufacturing market

. Leading businesses in this sector include1. Saint-Gobain A multinational corporation based in France, Saint-Gobain is a key player in the float glass market, providing innovative solutions for energy efficiency and sustainability in construction and automotive applications. 2. AGC Inc. Formerly known as Asahi Glass Co., AGC is a Japanese company recognized for advanced technologies in glass manufacturing. Their float glass is widely used across various industries, including electronics.

3. Guardian Industries Based in the United States, Guardian is a prominent manufacturer of float glass, specializing in architectural and automotive glass. The company emphasizes sustainability and offers a range of eco-friendly glass products.

4. NSG Group This Japanese company, known for its Pilkington brand, has a significant presence in the float glass market. NSG Group supplies high-performance glass products to sectors such as construction, automotive, and aerospace.

Future Trends and Challenges

The float glass industry is set to evolve in response to emerging market demands and environmental concerns. With an increasing focus on energy efficiency, manufacturers are developing low-emissivity (low-E) glass, which reflects heat while allowing natural light to penetrate. This innovation enhances energy efficiency in buildings, contributing to sustainability goals.

Another important trend is the rise of smart glass technology. This includes glass that can change its properties, such as tint or opacity, upon receiving an electrical charge. As smart glass becomes more mainstream, float glass manufacturers are exploring opportunities to integrate these advanced technologies into their product lines.

However, the industry also faces challenges. Fluctuations in raw material prices, strict environmental regulations, and competition from alternative materials pose significant hurdles. Manufacturers must adapt by adopting sustainable practices and exploring innovative solutions to stay competitive.

Conclusion

The float glass manufacturing industry is vital to modern society, and its foundational processes and leading manufacturers set the stage for continued innovation. As environmentally friendly solutions and advanced technologies gain traction, the future of float glass appears promising. By embracing change and remaining responsive to market demands, float glass manufacturers can maintain their relevance and contribute to a more sustainable future.