Understanding Float Glass Types A Comprehensive Guide

Float glass is a fundamental material used in a wide variety of applications, ranging from windows and doors to mirrors and automotive glass. The process of creating float glass was invented by Sir Alastair Pilkington in the 1950s, which revolutionized the glass manufacturing industry. The term float glass derives from the method in which molten glass is floated on a bed of molten tin to create a smooth, uniform surface. This article explores the various types of float glass, their applications, and the characteristics that make them unique.

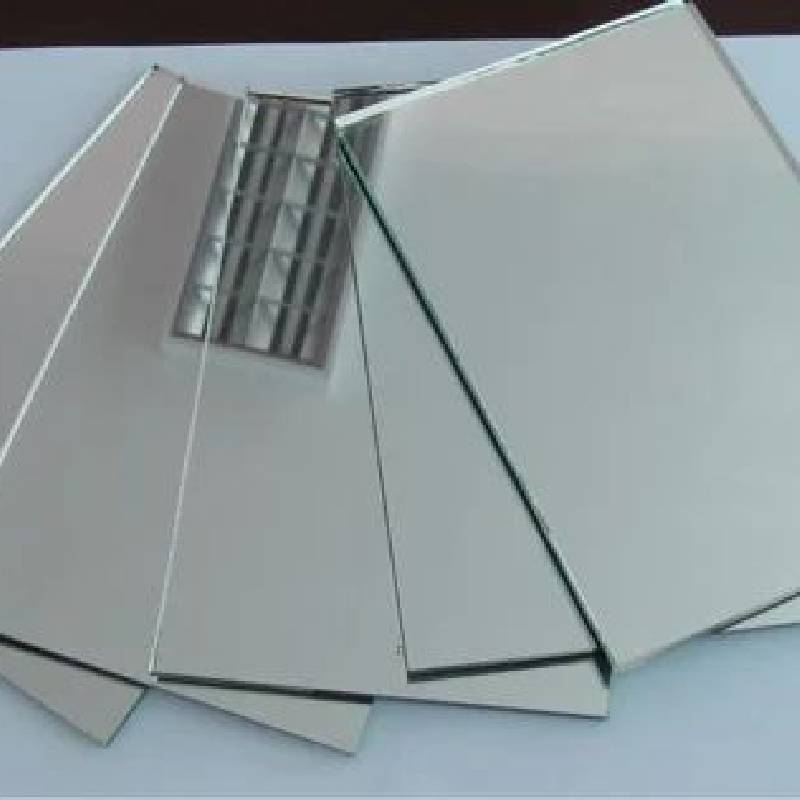

Types of Float Glass

1. Clear Float Glass This is the most basic form of float glass, which is transparent and colorless. It is widely used in the construction of windows, glass doors, and display cases. Clear float glass typically has excellent optical clarity and can be produced in large sheets, making it cost-effective for a variety of applications.

2. Low-Iron Float Glass While clear float glass may have a greenish tint due to the iron content in the raw materials, low-iron float glass is manufactured with lower levels of iron, resulting in improved transparency. This type of glass is often used in high-end architectural applications, where aesthetics are vital. It is favored for glass facades, signage, and furniture because it allows for better light transmission and a more accurate color representation.

3. Tinted Float Glass Tinted float glass is manufactured by adding colorants to the glass during production. This type of glass is commonly used in applications where glare reduction and privacy are desired. Tinted float glass can be utilized in commercial buildings, automotive windows, and residential applications, providing moderation of solar heat gain and enhancing energy efficiency.

4. Reflective Float Glass Reflective float glass has a thin metal coating that reflects solar rays while allowing visible light to pass through. This type of glass is often used in commercial buildings to improve energy efficiency and reduce heat absorption. Reflective float glass can create a striking aesthetic on the exterior of buildings, providing a sleek and modern look.

5. Laminated Float Glass Laminated glass consists of two or more layers of float glass that are bonded together with an interlayer, often made of polyvinyl butyral (PVB). This type of glass provides enhanced safety and security, as it holds together when shattered. Laminated float glass is commonly used in skylights, glass facades, and safety applications, making it an essential component in the construction industry.

6. Tempered Float Glass Tempered glass is subjected to a heat treatment process that increases its strength and thermal resistance. This type of glass is less likely to break under stress compared to standard float glass. Tempered float glass is used in a variety of applications, including shower doors, glass railings, and storefronts, where safety and durability are paramount.

7. Insulated Float Glass Insulated float glass, commonly referred to as double or triple glazing, consists of two or more panes of glass separated by a spacer filled with air or gas. This design improves energy efficiency by minimizing heat loss. Insulated glass is frequently used in residential and commercial buildings to enhance thermal performance.

Conclusion

Float glass is a versatile material that plays a critical role in various industries. The different types of float glass—ranging from clear and low-iron to tinted and insulated—serve specific functions that cater to diverse needs. Understanding the properties and applications of each type of float glass can help manufacturers, architects, and consumers make informed decisions when selecting glass products for their projects. As technology continues to advance, the development of new float glass types will likely enhance their functionality and expand their applications, making float glass an ever-evolving and essential material in our modern world.