2024 Industry Trends: The Rise of IGU Glass

The global demand for insulated glass units for sale has surged due to the worldwide emphasis on energy savings, environmental sustainability, and advanced building aesthetics. According to Statista 2023:

- Global IGU market size: Reached $23.7B in 2023, projected CAGR of 5.2% (2024–2029).

- Key sectors: Commercial glazing, residential energy retrofits, industrial cleanrooms, and transportation.

- Top growth regions: Asia-Pacific, North America, Middle East.

Modern IGU glass panels are pivotal in green construction, helping achieve international certifications (e.g., LEED, BREEAM), and are recommended by regulatory bodies like the U.S. ENERGY STAR Program.

Thermal efficiency of commercial IGU glass for sale

Key Parameters: IGU Glass for Sale Market Comparison (2024)

| Parameter |

Standard IGU |

Energy-saving IGU |

Triple-glazed IGU |

| U-value (W/m2·K) [ISO 10077-1] |

≤ 2.7 |

≤ 1.2 |

≤ 0.7 |

| Sound Insulation (dB) |

28–31 |

32–36 |

38–42 |

| Visible Light Transmittance (%) |

74–80 |

58–75 |

45–62 |

| Solar Heat Gain Coefficient (SHGC) |

0.72 |

0.62 |

0.51 |

| Argon Fill (%) |

0 |

80-95 |

98 |

| Lifecycle (Years) |

15~20 |

25~30 |

30~35 |

Data from National Glass Association, ISO 10077-1.

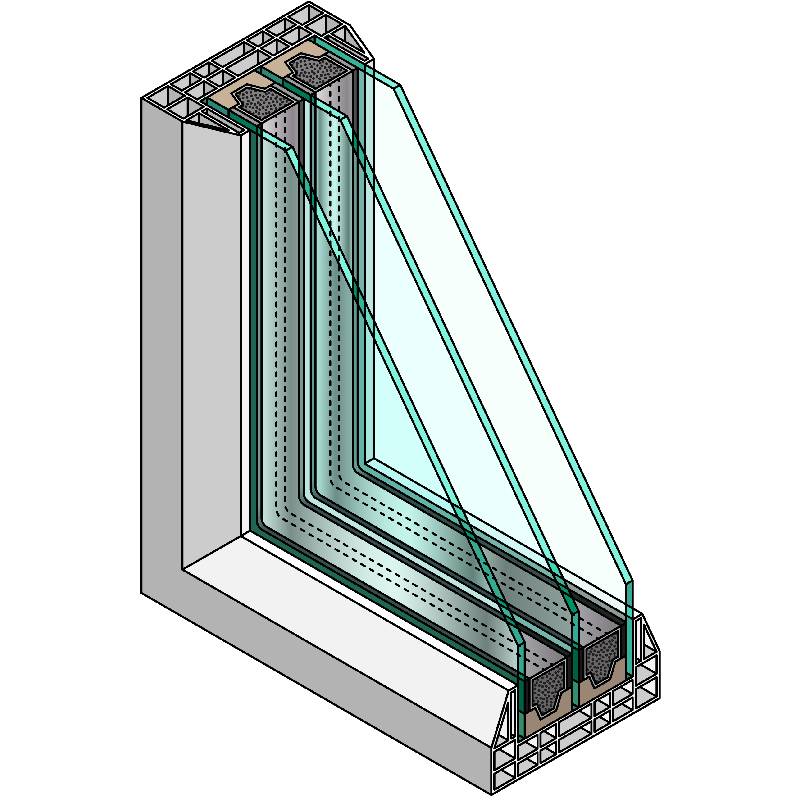

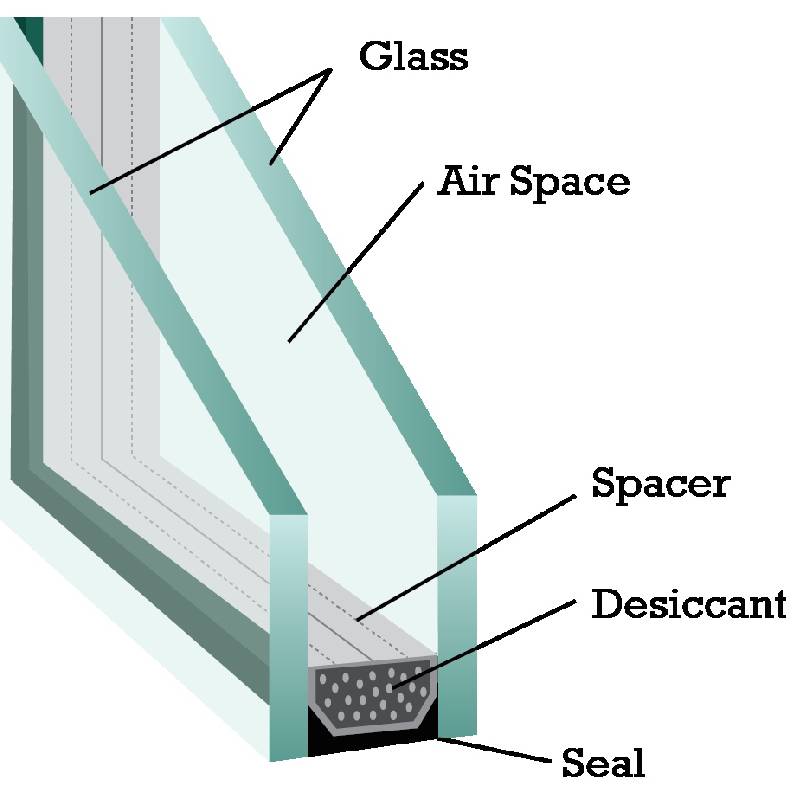

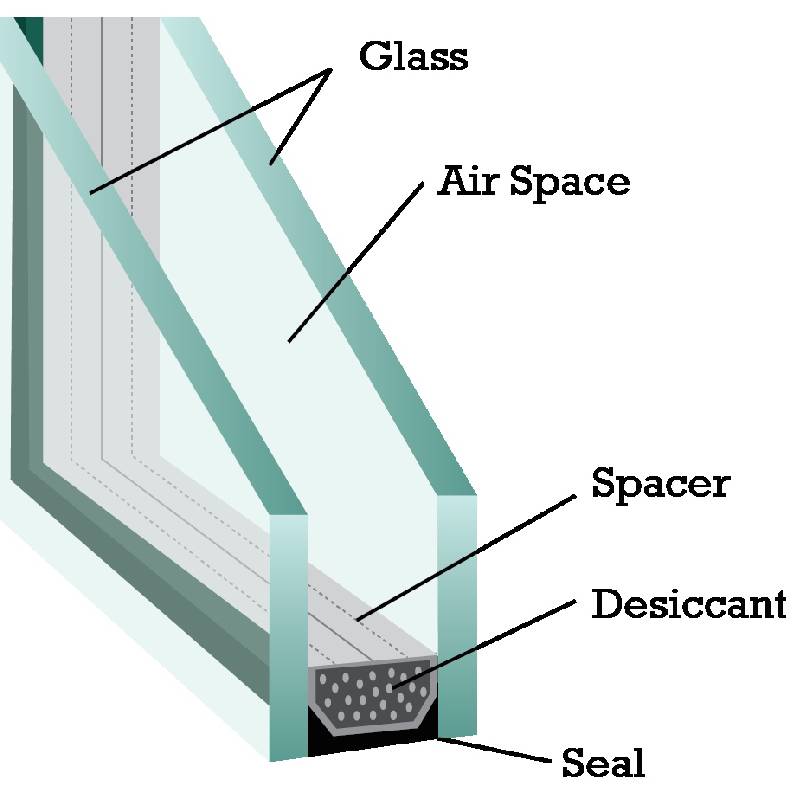

The technical superiority of IGU glass for sale lies in multi-layered structure, specialized gas fillings, and precision spacers – all ensuring performance under stringent ISO 12543/EN1279 certification.

Technical Specifications & Industry Certifications

- Thickness: 12mm–52mm (customizable); common: 5+12A+5mm, 6+16A+6mm, 8+12A+8mm.

- Max. Size: Up to 3300mm × 6000mm (as per EN12150-2:2019).

- Glass Types: Tempered (ANSI Z97.1), Low-E, Acid-etched, Laminated.

- Spacer Types: Warm-edge, Aluminum, Stainless steel; Super Spacer® available.

- Gas Fill: High-purity Argon (90–98%), Krypton, or Dry air.

- Sealant: Dual-component Silicone, PIB (Polyisobutylene), Hotmelt.

- Testing & Certification: ISO 12543, EN1279, ANSI Z97.1, ASTM E2190.

Performance: Thermal Insulation, Soundproofing, Dew/Fog Resistance

Factory-inspected igu glass panels prior to shipment

Main Standards Referenced:

- ISO 12543 (Glass in building—Laminated glass & IGU specification)

- EN 1279 (Insulating glass units—Durability & performance testing methods)

- ANSI Z97.1 (Safety glazing material—U.S. Standard)

- ASTM E2190 (North America—Sealed IGU performance test)

IGU units are frequently third party tested for resistance to condensation, argon retention, static load, and cyclic humidity (see SGS IGU Testing Service).

Typical Applications & Advantages of IGU Glass Units

🏢 Commercial Buildings (Office Towers, Malls)

- Reduce annual HVAC energy cost by up to 40% (per DOE).

- Superior sound insulation (32-42 dB) for urban environments.

- Custom laminated IGU glass panels for impact & burglary resistance (tested to EN356).

🏙 Residential (High-rise, Villas, Refurbishments)

- Enhanced comfort with Low-E IGU glass unit (minimizes indoor UV, eliminates condensation).

- Easy integration into PVC, aluminum, wood or steel frames.

- Up to 35 years service life with advanced warm-edge spacer systems.

🏭 Industrial & Special Applications

- Corrosion-resistant units for petrochemical, wastewater, cleanroom sectors.

- Anti-condensation IGUs meeting EN1279 Part 2 fogging and ISO 4892 UV-Resistance.

- Bullet-resistant & blast-rated options for high-security environments (EN1063 Ballistics, ISO 16933 Explosion)

Certified igu glass meets project needs in airports, metro stations, hospitals, luxury hotels, curtain wall facades, and sustainable renovations. Verified customer cases illustrate lifetime energy savings, noise reduction, and low maintenance vs. traditional glazing.

IGU Glass for Sale – Professional Q&A

1. What glass types are most common in IGU production?

Typically, IGU glass units incorporate float glass, tempered glass (for safety), Low-E coated glass (for energy efficiency), or laminated glass (for enhanced security & UV protection). Each glass type meets specific requirements per EN12150 or ANSI Z97.1 standards.

2. What is the optimal gas filling for energy-saving IGUs?

Argon gas (density 1.784 g/L) is most popular (up to 98% purity filling), improving thermal insulation by 30–45% over air. Krypton gas is used for high-performance, ultra-slim IGU glass panels, especially in triple glazing for passive house projects.

3. Which industry certifications should quality IGUs hold?

Mandatory certifications include ISO 12543, EN1279 (Europe), ANSI Z97.1 (USA), plus locally required SGS, BSI Kitemark, or CE marking. These ensure lifecycle, condensation, and structural safety.

4. What's the recommended IGU edge spacer material?

Warm-edge spacers (non-metallic or thermally improved metal) minimize edge thermal bridging, enhance condensation resistance and extend IGU lifetime. Standard metallic spacers (aluminum/stainless) are cost-effective but less thermally efficient.

5. How is sealant selection critical for IGU durability?

Dual sealant systems (primary butyl-based PIB, secondary silicone) per ISO 11600 are essential. They provide moisture vapor barrier, long-term UV and chemical resistance, and are tested under accelerated heat/moisture cycles (per ASTM E2190).

6. Do IGUs require any special installation standards?

Yes, professional IGU glass unit installation should comply with ASTM E2112 and local building codes, ensuring correct packers, frame ventilation, and no direct sealant contact with organic gaskets. Perimeter must not be under permanent moisture stress.

7. What is the industry-typical warranty and support for IGUs?

Leading suppliers offer

10–15 year warranty against fogging or seal failure; up to

15–25 years with advanced warm-edge products.

24/7 support, technical consultancy, and on-site assistance are available with

IGU glass for sale from TPTOP Glass.