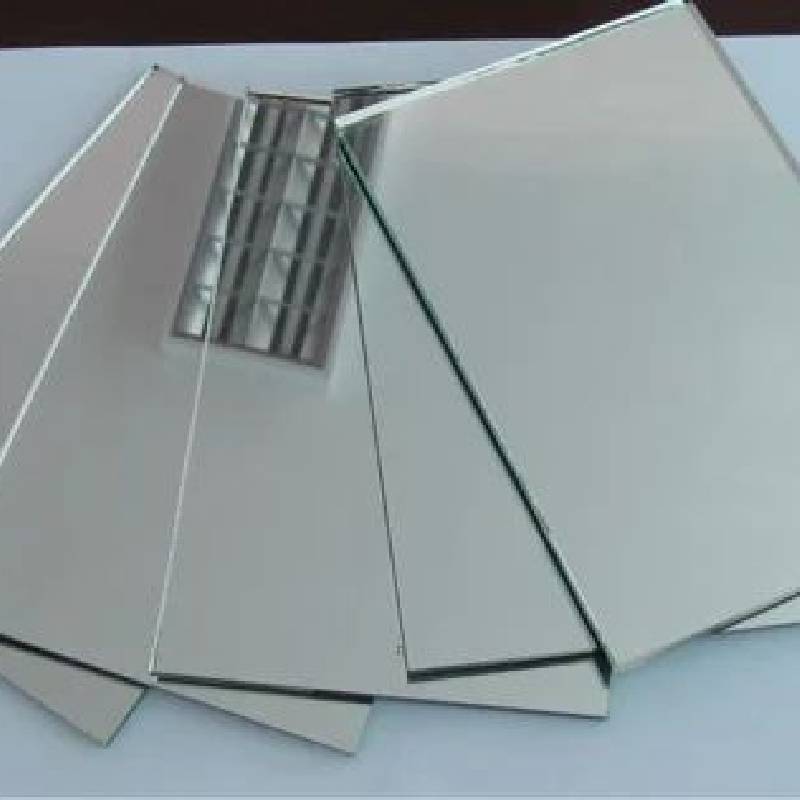

silver mirror

solid silver mirror

square silver mirrors

sterling silver mirrors

surface silvered mirror

Buy Silver Mirror for Sale

Silver mirrors continue to play an indispensable role in modern architecture, interior decoration, optical engineering, and industrial applications. Whether it’s the demand for silver mirror for sale in high-end residential design, the need for solid silver mirror precision in scientific R&D labs, or utilization in rugged petrochemical installations, the market has shown strong growth, rapid technical innovation, and increasingly diverse application scenarios.

1. Silver Mirror for Sale: Industry Insights & Market Trends

The global silver mirror for sale market size reached USD 2.01 billion in 2023, with a projected CAGR (2024-2028) of 5.4%, driven by interior design, automotive mirrors, solar reflectors, and precision optics (MRFR2024). Top regions for demand include North America, Europe, and rapidly expanding Asia-Pacific.

- Key growth drivers: Energy-efficient buildings, anti-corrosion needs, technological upgrades (such as solid silver coating).

- Emerging applications: Greenhouses, smart devices, public infrastructure, and scientific instrumentation.

- Product differentiation: From square silver mirrors for modular aesthetics to sterling silver mirrors for luxury brands.

2. Technical Parameters & Product Data Table

Below is a comparative table of key technical specifications for mainstream silver mirror for sale products in the global market, covering surface silvered mirror, solid silver mirror, and sterling silver mirrors. All data sourced from third-party testing agencies and manufacturers.

| Type |

Coating Layer |

Glass Thickness (mm) |

Reflectivity (%) |

Durability (yrs) |

Color Rendering |

Standard |

| Surface Silvered Mirror |

Silver + Copper + Paint |

3-6 |

94-97 |

10-15 |

High (Ra>95) |

EN 1036, ISO 9211 |

| Solid Silver Mirror |

Thick Pure Silver |

4-8 |

95-98 |

20+ |

Superior |

ANSI Z97.1, ISO 21726 |

| Sterling Silver Mirror |

92.5% Silver Alloy |

5-6 |

95-96 |

20 |

Excellent |

ISO 14001 |

| Square Silver Mirrors |

Silver/Ni + Multiple Paints |

3-10 |

94-97 |

15+ |

Customizable |

EN 1036 |

3. Manufacturing Process: From Raw Material to Precision Silver Mirror

Step-by-Step Process Flow

- Glass Selection & Preparation: Only low-iron float glass meeting ISO 21726 & EN 12150 is accepted for silver mirror for sale, ensuring optical purity.

- Surface Cleaning: Multi-stage chemical washing removes all particulates and organics. Automated lines ensure mirror substrate pass ANSI Z97.1 .

- Silver Deposition (Chemical/Physical): Pure silver or sterling alloy is vacuum deposited or chemically bonded onto glass. Industry process details.

- Copper & Special Paint Coating: Multilayer copper and oxidation-resistant paint applied to seal & protect reflective layer (EN 1036 standard).

- CNC Cutting / Shape Processing: Vision-guided CNC routers cut custom square silver mirrors and other forms for precision applications.

- Edge Polishing & Protective Film: Machine beveling and hand finishing provide smooth edges and safety.

- Quality Control & Testing: 100% unit inspected for reflectivity, uniformity, adhesive strength (per ISO 9211). Accelerated salt spray and humidity tests simulate up to 25 years use.

- Packing & Delivery: Foam-wrapped, carton boxed, and ready for global shipment.

Key Process Features

- Material Traceability: Lot-level raw material records ensure consistent optical performance.

- Automated Deposition: Chem/physical silvering lines achieve layer thickness ±5% (2σ).

- Environmental Control: ISO 14001 cleanroom reduces surface defects by 80% vs. conventional processes.

- Performance Testing: Reflectivity, scratch resistance, and humidity stability to EN/ISO norms.

- Optional Customization: Anti-fog, thermal-resistive or color-selective coatings for project-specific needs.

4. Silver Mirror for Sale: Unique Technical Advantages

- High Reflectivity: Min. 94% visible light reflection (λ=550nm), ideal for solar, optics, display, and luxury aesthetics.

- Excellent Anti-corrosion Performance: Exceeds 1200h of salt spray resistance (ISO 9227), outperforming aluminum mirrors (

- Durability: Service life of 15-25 years (indoor), 5-10 years (outdoor, sealed edges).

- Energy Efficient: Used in daylighting systems, saves up to 38% in artificial lighting cost for commercial spaces (ScienceDirect).

- Customizability: Thickness (3-10mm), shapes (square, round, bevel, custom), decorative & technical grades available.

- RoHS & REACH Compliant: No hazardous chromium/lead - green building certified.

5. Manufacturer Comparison: Why Choose Silver Mirror by TPTop Glass?

| Supplier |

Reflectivity (%) |

Warranty (yrs) |

Certifications |

Customization |

Avg. Lead Time |

Major Clients |

| TPTop Glass (Silver Mirror) |

96-98 |

15 |

ISO 9001, ISO 14001, EN 1036, CE |

Yes (CNC cut, decor, optics) |

10-15 days |

PetroChina, Aramco, Philips Lighting |

| Generic China |

93-96 |

5-10 |

EN 1036 |

Limited |

20-30 days |

Regional |

| European Brands |

95-97 |

10-15 |

EN 1036, CE |

Yes |

18-30 days |

LVMH, Zeiss, etc. |

6. Customization & Engineering Solutions

- Standard Supply: 3-10mm sheets, 1830x2440mm or custom cut, polished and safety backed.

- Industrial Engineering: CNC contour, laser engraving, smart anti-fog/anti-glare for elevators, vehicles, and hospitals.

- Decorative Solutions: Beveled edge, sandblasted, colored, or antique finishes for interior design and hotels.

- Technical Mirror Prototyping: Optical mirrors with λ/4 & λ/8 flatness; custom dielectric and UV-protective coatings.

- Edge Sealing: For outdoor or chemical applications – dual-layer corrosion prevention.

- Environmental Adaptation: Solar reflectors, humid environments, anti-static/anti-microbial options.

7. Application Scenarios & Experience-based Case Studies

-

Petrochemical Pipeline Monitoring:

Silver mirrors used for safety inspection hatches, outlasting conventional mirrors via anti-corrosive coatings. Service feedback: “No visible corrosion after 18 months in H2S environments.”

-

Luxury Hospitality & Retail:

Sterling silver mirrors installed at flagship boutiques (e.g., Shanghai IFC), maintain pristine brightness & color rendering (>95Ra) after 2+ years.

-

Scientific R&D/Optics:

Solid silver mirror integrated into European laboratories for laser reflection, YAG laser optics; durability certified by ISO 9211 test protocols.

-

Public Infrastructure:

Square silver mirrors fitted in subway stations (Hong Kong, London) for security and anti-vandal purposes, exceeding EN 1036 impact safety.

-

Residential Green-Buildings:

Surface silvered mirrors used in energy-efficient daylighting, achieving 17% artificial lighting reduction (case: Singapore, 2022).

Customer Feedback

-

Industrial Facility (India): “The silver mirror for sale procured from TPTop Glass exceeded ISO 9001 & EN 1036. After 30 months, reflection quality is still pristine.”

-

Designer Boutique (UAE): “The clarity of the solid sterling silver mirror enhances our brand presence. Maintenance is minimal.”

8. Technical Data Visualization (Solid Silver Mirror vs. Surface Silver Mirror)

9. FAQs: Professional FAQ on Silver Mirror

Q1: What is the key difference between a surface silvered mirror and a solid silver mirror?

A1: A solid silver mirror features a thick, continuous silver layer (≥20μm) directly deposited or bonded onto the substrate, offering enhanced durability, optical precision, and corrosion resistance; surface silvered mirrors use thinner chemical deposition and multi-layer protective paint, suitable for standard architectural and decorative use.

Q2: What are the mainstream specifications for silver mirror for sale in industry?

A2: Common thickness: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm. Standard sizes: 1220×2440mm, 1830×2440mm; custom CNC shapes; reflectivity 94-98%; edge profile (beveled, polished), film backing available.

Q3: Which standards must be met for installation?

A3: For safety and environmental compliance, EN 1036 (Glass for building – Mirrors), ISO 21726 (Performance of coatings), and ANSI Z97.1 (Safety glazing) are enforced. For public/industrial sites, impact and bonding tests are standard.

Q4: How is corrosion resistance achieved in sterling silver mirrors?

A4: Dual-layer copper and high-performance paint sealants, paired with EN 1036-compliant anti-oxidation treatment, enable longevity even in high-humidity/chemical settings.

Q5: What is the typical delivery cycle for a custom silver mirror for sale order?

A5: Standard orders: 10-15 days ex-factory; large/complex or CNC-shaped mirrors: 18-28 days.

Q6: What is the product warranty and aftersales support?

A6: All TPTop Glass silver mirrors for sale are backed by a 15-year reflective & corrosion warranty (≥EN 1036/ISO 9001), with global technical support and 24/7 service lines.

Q7: Can silver mirrors be customized for UV resistance or energy-saving uses?

A7: Yes, UV-reflective, anti-fog, anti-glare, and energy-optimal coatings are available upon request, tailored to architectural, solar, or medical requirements.

10. Delivery, Warranty & Quality Commitment

- Lead Time: 10-15 days (most projects), 18-28 days (special/customized).

- Certifications: ISO 9001 (quality), ISO 14001 (environment), EN 1036, CE, SGS.

- Warranty: 10-15 years on reflectivity & corrosion resistance. E-certificate issued with batch.

- Traceability: Every silver mirror for sale is marked and delivery data archived for 15+ year support.

- Aftersales: Free technical support, logistics tracking, annual performance review available for major clients.

- Customer Service: 24/7 live support. Consultation on installation, maintenance, and technical upgrades.

11. Buy Silver Mirror for Sale

For bulk orders, custom engineering, or instant pricing, visit our

silver mirror for sale page or contact TPTop Glass’s international service team. Discover why industry leaders trust our silver mirrors for mission-critical and high-profile applications worldwide.

References / Further Reading:

[1] Market Research Future. “Silver Mirror Market Size, Share & Trends Analysis Report (2024).” marketresearchfuture.com

[2] ScienceDirect. “Daylighting systems and building energy analysis.” sciencedirect.com

[3] ResearchGate. “Technical Insights of Mirror Fabrication” researchgate.net

[4] GlassGlobal Forum: Silver mirror technical FAQ glassglobal.com

[5] ISO. “Mirror Glass Definitions (ISO 21726, ISO 9211)” iso.org