The tempered glass market has seen considerable shifts due to the evolving demands of technology, architecture, and consumer electronics. To navigate these changes effectively, one must delve into the experience-based insights, technical expertise, authoritative resources, and trustworthy data that shape this industry's pricing landscape.

An understanding of tempered glass begins with its manufacturing process. Tempered glass undergoes a thermal tempering process where it is heated to over 600°C and then rapidly cooled. This treatment increases its strength and makes it safer than ordinary glass, as it breaks into small, less harmful pieces. This inherent quality places tempered glass as a preferred choice in automotive, architectural, and electronic applications.

The cost of tempered glass is influenced significantly by the thickness and type required. For example, thicker variants provide higher safety and insulation benefits, making them ideal for construction purposes, but these benefits come at a higher price point. Technological advancements have enabled manufacturers to produce ultra-thin tempered glass, which is increasingly used in smartphones and tablets. A direct correlation exists between the technological sophistication in manufacturing processes and the cost passed onto consumers.

Market dynamics also play a pivotal role. Fluctuations in raw material costs, specifically silica sand and soda ash, and energy prices impact the cost structure of tempered glass. Manufacturers have to adapt to these variations while maintaining product quality, often leading to price adjustments. Importantly, global trade policies and tariffs on glass materials can either elevate or suppress market prices, creating a competitive atmosphere among suppliers.

From an experience viewpoint, consumers and businesses seeking tempered glass for various applications must weigh their requirements against market offerings. For instance, a furniture manufacturer may prioritize aesthetic transparency and scratch resistance, whereas a builder might focus on thermal insulation and safety. This situational consideration affects how much buyers are willing to pay, and thus, pricing strategies among suppliers can vary significantly.

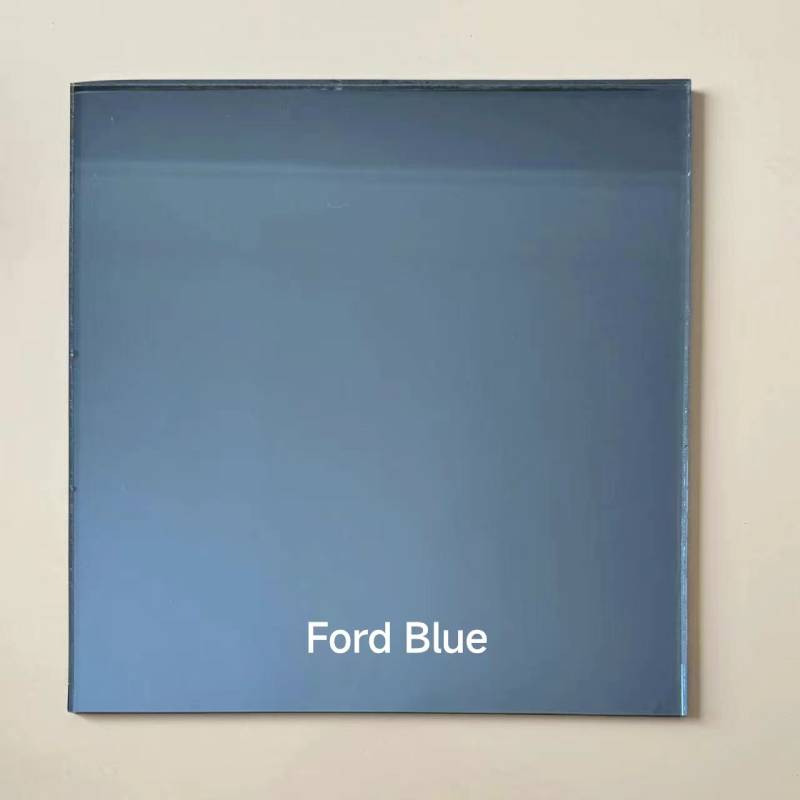

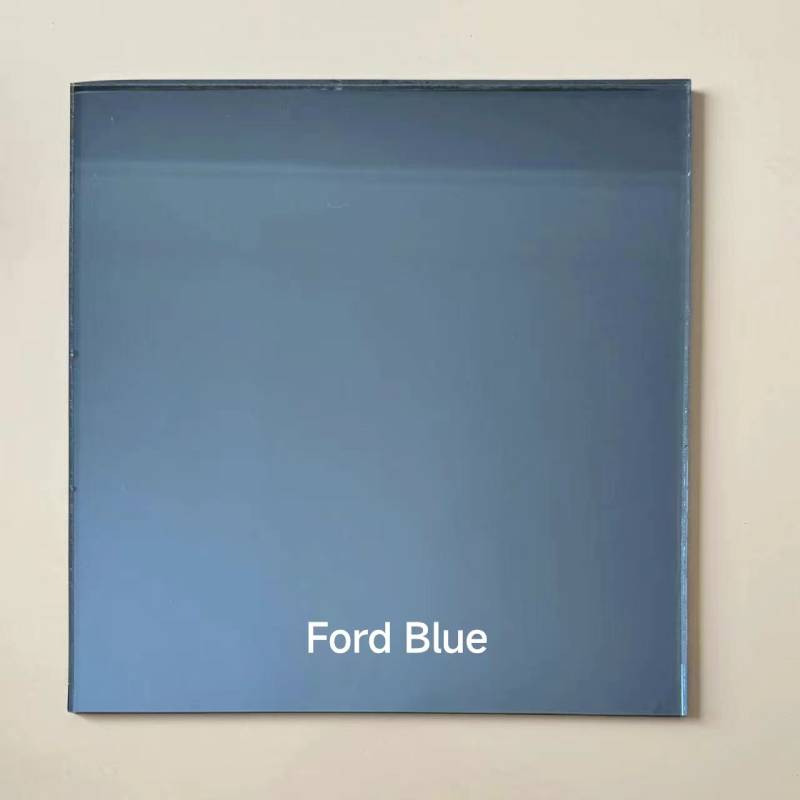

tempered glass price

Expertise in the field of tempered glass production involves a deep understanding of both the technical specifications and the intended applications. In automotive industries, where tempered glass meets specific safety regulations, experts must consider these guidelines when advising on price points. Similarly, in consumer electronics, product development teams must focus on integrating durable yet lightweight materials, directly impacting cost due to the precision required in manufacturing.

Authority in this domain comes from recognized organizations and industry standards that govern production and quality assurance. The International Organization for Standardization (ISO) and relevant safety certification boards provide these guidelines, ensuring credibility and uniformity in products across different regions. Businesses can rely on these standards to assure customers of the safety and reliability of tempered glass products, thus affecting consumer confidence and pricing.

Trustworthiness in tempered glass pricing also stems from transparent business practices and sustainability initiatives. Companies committed to eco-friendly production methods and ethical sourcing are often perceived as more reliable, allowing them to charge a premium. Transparency in pricing, whereby companies disclose the factors contributing to cost, also builds consumer trust, encouraging long-term business relationships.

In conclusion, tempered glass pricing is a complex interplay of manufacturing prowess, market conditions, consumer demand, and regulatory frameworks. By understanding these aspects through a lens of experience, expertise, authority, and trustworthiness, stakeholders can make informed decisions, ensuring their investments in tempered glass are economically sound and quality-driven.