Tempered safety glass, a marvel of modern engineering, emerges as a paramount product in industries ranging from construction to automotive manufacturing. Renowned for its enhanced strength and safety features, this sophisticated material contributes significantly to innovation and safety across multiple applications.

Experience with tempered safety glass reveals its transformative impact on building and vehicle safety. In architecture, this glass is highly favored for its ability to withstand considerable pressure and temperature fluctuations. During installation in skyscrapers and other high-rise constructions, contractors report that its robustness considerably reduces breakages common with conventional glass. Similarly, within the automotive sector, manufacturers incorporate tempered glass into vehicle windows and windshields, noting a drastic improvement in passenger safety during accidents. The glass, engineered to shatter into small, blunt pieces rather than dangerous shards, minimizes injury risk—a feature lauded by automotive safety experts.

Expertise in producing tempered safety glass involves understanding the precise process by which it is manufactured. This glass undergoes thermal or chemical treatments that increase its strength several times over compared to standard glass. Glass manufacturing specialists explain that the glass is heated to over 600 degrees Celsius and then rapidly cooled, a process known as tempering. This method induces a state of compression on the surface while maintaining tension within its core, giving it its remarkable properties. Given its complexity, mastering this process demands a high degree of precision and quality control, ensuring each pane meets stringent safety and performance standards.

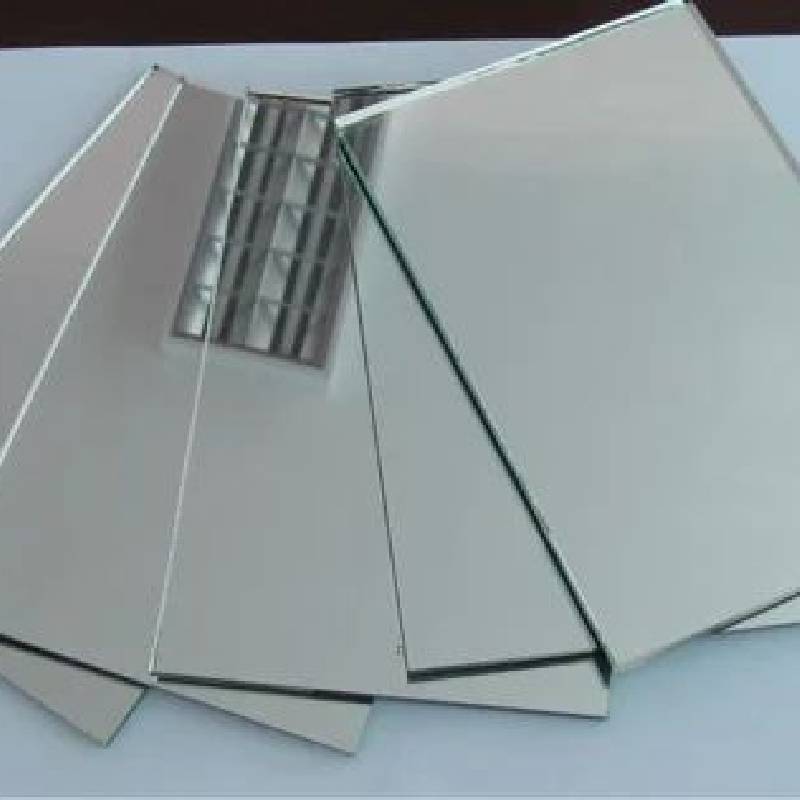

tempered safety glass

Authoritativeness in the tempered safety glass industry is evidenced by rigorous testing and certification from reputable bodies. Safety glass must comply with standards set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), which define the safety, impact, and human impact requirements for glass used in buildings and transport. Companies recognized in the industry are often those that consistently meet or exceed these benchmarks, producing glass that passes mandatory ball drop tests, impact tests, and fragmentation checks. These firms not only lead in production but also contribute to setting new industry standards, showcasing their authority and reliability in safety glass innovation.

Trustworthiness of tempered safety glass products hinges on transparency and adherence to regulations. Leading manufacturers prioritize full disclosure of their production processes and provide certifications that affirm their glass's compliance with safety standards. Moreover, they engage in continuous research and development, aiming to enhance the properties of tempered glass further. Trust is also built through customer testimonials and long-term warranties, which assure consumers of the glass's durability and safety. Furthermore, partnerships with globally recognized regulatory agencies reinforce trust, assuring customers that the glass is indeed a protective and reliable choice for any application.

Tempered safety glass serves as a pivotal component in ensuring safety and reliability across sectors. Its embedded strength, derived from advanced tempering techniques, sets a high standard for safety. The expertise involved in its creation ensures it remains a benchmark for safety materials, while authoritative compliance with industry standards and transparent business practices assures its continued trustworthiness in the market. Those seeking products that excel in safety and performance can rely on tempered safety glass to deliver unparalleled protection and peace of mind.