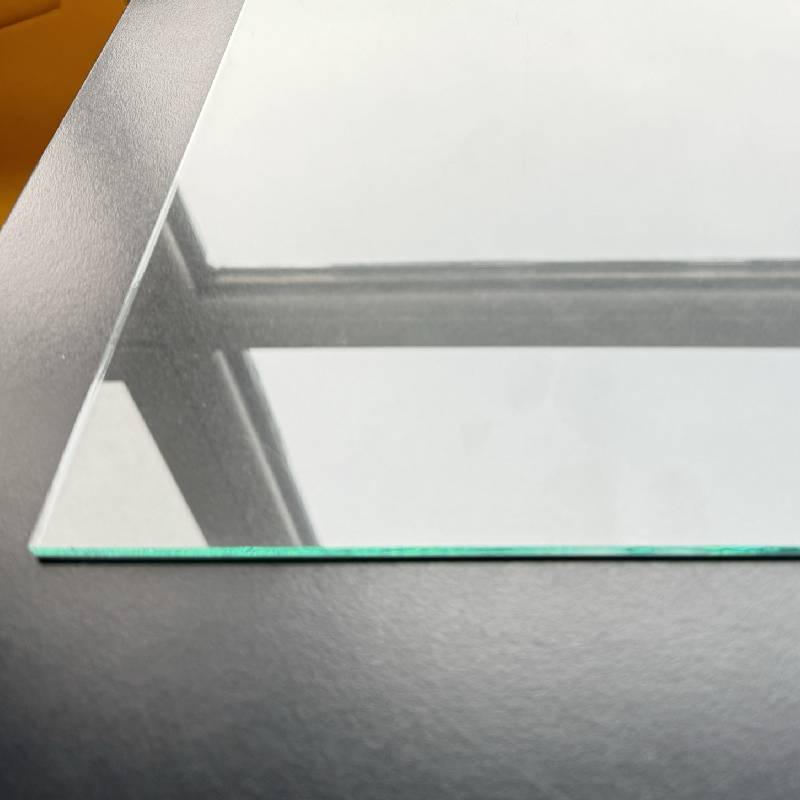

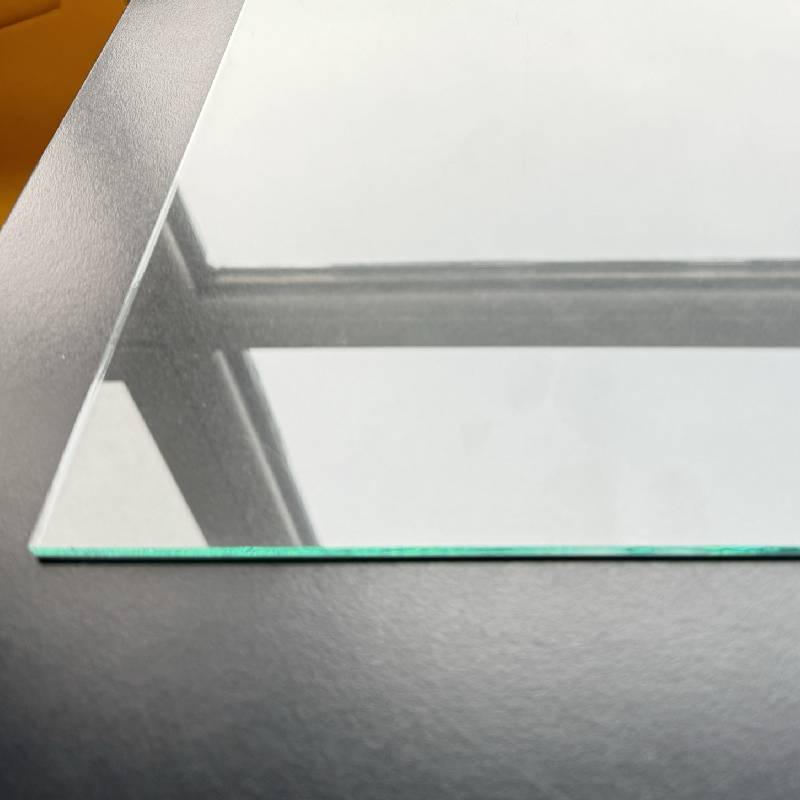

Ultra clear glass, also recognized as ultra clear float glass or extra clear float glass, is setting new benchmarks in architectural, industrial, and public infrastructure projects. With unparalleled transparency, low iron content, and advanced tempering, ultra clear glass like Clear Float Glass is powering a revolution in engineering design, daylighting, and energy-efficient solutions.

Industry Trends: The Rise of Ultra Clear Glass in Modern Construction

- Global demand for ultra clear glass surpassed 2.1 million tons in 2023 (Statista), driven by green building codes and façade innovation.

- Rapid adoption in smart cities, luxury real estate, high-end optical displays, and solar energy modules.

- Projected CAGR (2024-2028) for "low iron ultra clear glass": 7.2% (Source: MarketsandMarkets).

- Key driver: Stricter ANSI Z97.1, EN 12150 safety & performance regulations and the push for high-clarity in public and commercial architecture.

Keywords: ultra clear glass, ultra clear float glass, extra clear float glass, low iron ultra clear glass, ultra clear tempered glass, clear float glass

Technical Parameters: Specifications and Product Data Visualization

Understanding the ultra clear glass technical data is vital for designers and procurement engineers. Explore the comparative table below for mainstream high-clarity glass products:

Table 1: Parameter Comparison - Ultra Clear Glass & Conventional Glass

| Parameter |

Ultra Clear Glass |

Conventional Float Glass |

Ultra Clear Tempered Glass |

Low Iron Ultra Clear Glass |

| Iron Content (Fe₂O₃, ppm) |

100-120 |

600-1200 |

100-120 |

≤120 |

| Light Transmittance (%) |

91-93 |

82-84 |

91-92.5 |

91-93 |

| Thickness Range (mm) |

3 - 19 |

3 - 19 |

6 - 19 |

4 - 19 |

| Color Appearance |

Extra white, flawless |

Greenish tint |

Extra white |

Crystal clear |

| UV Transmission (%) |

58-62 |

53-57 |

58-61 |

60-65 |

| Bending Strength (MPa) |

>50 (float) |

35-50 |

>120 (tempered) |

50-60 |

| Certifications |

ISO 9001, ANSI Z97.1 |

ISO 9001 |

ANSI Z97.1, EN12150 |

ISO 9001 |

Figure 1: Light Transmittance Comparison

Manufacturing Process: How Ultra Clear Glass is Made

Raw Material Selection

Ultra-pure silica sand, soda ash, dolomite.

Low Fe₂O₃

→

Batch Mixing & Furnace Melting

Computer-controlled blending, melted at 1,600°C

→

Float Forming

Melt flows onto molten tin bath to form uniform glass ribbon

→

Annealing

Controlled cooling to relieve stress (lehr oven)

→

Cutting & CNC Finishing

Precision CNC trimming, drilling, beveling up to 0.1mm tolerance

→

Quality Inspection

ANSI/ISO full optical & visual checks, impact testing, flaw detection

→

Packaging & Logistics

Protective film wrapping, custom crates, RFID tracking

Material Properties and Certifications

- Material: Extra-clear soda-lime silica glass (low iron content, Fe₂O₃ ≤ 120ppm)

- Production: Float method (continuous, non-distorting, high surface flatness)

- Finishing: CNC-edge grinding, polishing, waterjet cutting

- Physical Properties: Density 2.5 g/cm³, Modulus of Rupture up to 120 MPa (tempered)

- Optical Properties: Visible Light Transmittance ≥ 91%

- Standards Met: ISO 9001:2015, ANSI Z97.1, EN12150, ASTM C1036, RoHS

- Service Life: 25+ years (indoor/outdoor), UV and corrosion-resistant

All batches are subject to EN410 and GB15763.2 testing protocols, with advanced flaw detection (laser or fluorescent).

Application Scenarios: Where Ultra Clear Glass Excels

Ultra clear glass is the preferred choice across technologically demanding and design-oriented sectors:

Table 2: Top Application Scenarios

| Application |

Key Benefits |

Specification |

Reference Projects |

| Building Façades & Skylights |

Low visible distortion, brilliant daylight |

8/10/12mm, 91-92% transmittance |

Shanghai Tower, Burj Khalifa lobby |

| Ultra Clear Shower Glass |

Neutral color, luxury feel, no green edge |

8-12mm, edge polishing |

Hilton, Marriott bath design |

| High-end Display Cases |

Color neutrality, high impact resistance |

6-19mm, tempered/laminated |

Hermès, Rolex flagship |

| Solar PV/Greenhouse Panels |

Enhanced solar transmission |

4-6mm, AR coating |

SunGrow Farms, Tesla solar |

| Industrial Observation Windows |

Corrosion resistance, high clarity |

8-19mm, CNC cut-outs |

PetroChina, Siemens |

Technical Strengths of Ultra Clear Glass

- Unrivalled Clarity: Fe₂O₃ levels ≤120ppm deliver a nearly colorless finish for pure daylight and precise color rendering.

- High Mechanical Strength: Especially as ultra clear tempered glass, modulus of rupture >120 MPa.

- Chemical Durability: Acid and alkali resistant—suitable for petrochemical/refining environments.

- Processing Flexibility: Supports precision drilling, waterjet cutting, complex CNC shaping for custom facades and instrumentation ports.

- Energy Performance: Compatible with Low-E or solar control coatings for advanced energy-saving architecture.

- Longevity: Weather-resistant for ≥20 years with retained optical performance (>91% LT at 15 years, per Glassonweb Study)

Figure 2: Ultra Clear Glass Market Application Share (% est., 2023)

Clear Float Glass vs. High-End Alternatives

Clear Float Glass remains a competitive solution for most architectural, industrial, and display uses. Here's a performance comparison across key attributes:

Table 3: Ultra Clear vs. Starphire™ vs. Extra Clear Float

| Brand & Model |

Iron (Fe₂O₃ ppm) |

Light Transmittance (%) |

UV Resistance |

Color Index (ΔE 2000) |

Service Life (years) |

| Clear Float Glass |

≤120 |

91-93 |

High |

<0.3 |

25+ |

| Guardian UltraClear™ |

≤110 |

92-93 |

Very High |

<0.2 |

30 |

| Pilkington Optiwhite™ |

100 |

91-92.7 |

High |

<0.25 |

25+ |

| AGC Clearvision™ |

95-110 |

91.5-92.8 |

High |

<0.28 |

25+ |

-

Clear Float Glass (from TPTOP GLASS) is certified to ISO 9001:2015, with third-party SGS testing available.

-

Our surface flatness (≤0.1mm/m²), light distortion value (<0.2% at 1.0m), and color rendering are verified in accordance with GB/T 15763.2, EN410.

Figure 3: Light Transmittance vs. Thickness (Source: EN410 Data)

Inquire: Clear Float Glass

Customization Services & Delivery

-

Thickness: 3-19mm available

-

Max Dimensions: 3300mm x 6000mm

-

Edge Options: Flat/pencil/beveled/polished

-

CNC Machining: Holes (ø5-60mm), notches, shaped cuts, recesses

-

Tempering: Standard, semi-tempered, heat-soak tested

-

Laminating: PVB/SGP/IONOPLAST safety glass solutions

-

AR/Chemical Coatings: Optional for anti-glare, solar control, anti-fingerprint

Standard Lead Time: 12-16 days from drawing confirmation; rush services by request.

Packing: International seaworthy crates, desiccants, and customized labeling.

Warranty: 10 years optical clarity, edge stability, and anti-yellowing. SGS/Intertek documentation offered.

Customer Experiences & Reference Cases

-

Siemens AG (Germany): "Consistent edge quality and minimal color deviation for industrial machine vision windows."

-

Park Hyatt Shanghai: "Brilliant clarity of ultra clear shower glass transformed the guest bathroom ambiance."

-

Tesla Gigafactory Solar Division: "Low iron, high-transmission panes improved PV module output by 6% over conventional float glass."

-

Houston Museum of Fine Arts: "Display cases built with extra clear float glass—perfect color neutrality and security."

Our technical team has 15+ years serving over 1,300 B2B clients in petrochemicals, true estate, energy, transportation, and luxury hospitality. References available on request.

FAQ: Professional FAQ on Ultra Clear Glass

- Q1: What material composition sets ultra clear glass apart?

-

A: The key is ultra-low iron content (Fe₂O₃ ≤ 120ppm), achieved by selecting purified silica sand. This nearly eliminates the greenish hue found in standard float glass.

- Q2: Which international certifications does your clear float glass meet?

-

A: Our glass is certified to ISO 9001:2015 (quality management), ANSI Z97.1 (safety glazing), and is compliant with EN12150 (tempered), ASTM C1036 (quality standards), and RoHS environmental directives.

- Q3: Can you explain what "light transmittance" and "color rendering index" mean in glass selection?

-

A: Light transmittance (LT) is the % of visible light that passes through. Color Rendering Index (CRI) measures color accuracy as seen through glass—high CRI (≥97%) ensures true color perception, essential in display and daylighting applications.

- Q4: What defines "ultra clear tempered glass," and when is it used?

-

A: It’s ultra clear glass heat-treated for 4-5x higher strength, required in safety glazing (showers, facades, balustrades) to meet ANSI Z97.1 and EN12150 break safety standards.

- Q5: What is your maximum glass sheet size and dimensional tolerance?

-

A: Up to 3300x6000mm; tolerance typically ±0.2mm on length/width, ≤0.1mm/m² for flatness, after CNC edge finishing.

- Q6: What installation standards or best practices apply to ultra clear glass?

-

A: Always align with ASTM C1048 (installation), use proper gasket/sealant compatible with low iron glass, and support edges fully to prevent spontaneous breakage, especially for large area applications.

- Q7: Is the product suitable for chemical, petrochemical, or corrosive environments?

-

A: Yes; ultra clear float glass is highly resistant to acids/alkalis (except HF acid), making it ideal for industrial viewports in refineries, laboratories, desalination plants, and corrosive process lines.

Professional Support & Guarantees

-

Technical Support: 24/7 engineering consult, CAD file review, custom installation guides.

-

Sample Policy: Free A4 samples (3-12mm), international express shipment.

-

After-sales: On-site inspection, breakage accountability (shipping/photo evidence), instant replacement or refund.

-

Industry Partnership: 5+ years preferred supplier for petroleum/petrochemical, building facade, and luxury hotel groups worldwide.

-

Documentation: ISO/SGS/EN12150 reports downloadable per batch.

Why Choose Clear Float Glass for Your Project?

Clear Float Glass offers a robust combination of technical performance, visual excellence, and proven longevity, independently verified by leading third-party authorities and adopted across signature global projects. As market demand for light, transparency, and eco-performance grows, ultra clear glass stands at the forefront of glass technology.

Contact for Custom Solution