Understanding the Price of 12mm Tempered Glass

When it comes to architectural design and construction, tempered glass has become a popular choice due to its strength, durability, and safety features. Among various thicknesses available, 12mm tempered glass is often sought after for its balance between sturdiness and aesthetic appeal. However, understanding the factors that influence its price can be crucial for project budgeting and decision-making.

Tempered glass, also known as toughened glass, is produced through a rigorous thermal process that increases its strength compared to regular glass. This process involves heating the glass to over 600 degrees Celsius and then rapidly cooling it. As a result, tempered glass is approximately five to six times stronger than standard glass of the same thickness. This enhanced strength allows it to withstand high impacts and thermal stress, making it ideal for a variety of applications, including windows, shower doors, partitions, and facades.

Understanding the Price of 12mm Tempered Glass

Geographic location plays a significant role in pricing. In regions where there is a high demand for construction materials, such as urban centers, prices for tempered glass can be higher due to increased demand and transportation costs. Conversely, in areas with lower demand, prices may be comparatively lower. Furthermore, the logistics of transporting large, fragile sheets of glass can add to the overall expense.

Another significant factor is market demand. The construction industry often sees fluctuations based on economic conditions, seasonal trends, and regional developments. For instance, during a construction boom, the demand for tempered glass, including the 12mm variety, can spike, leading to higher prices. Manufacturers often respond to this demand by increasing prices, and conversely, during economic downturns or slower construction periods, prices may decrease as suppliers try to maintain sales volumes.

Additionally, the supplier’s pricing strategy can significantly influence the cost. Companies may designate different price points based on their reputation, production capabilities, and service offerings, such as processing and delivery. It is important for buyers to compare quotes from multiple suppliers to ensure they are getting competitive pricing while ensuring quality.

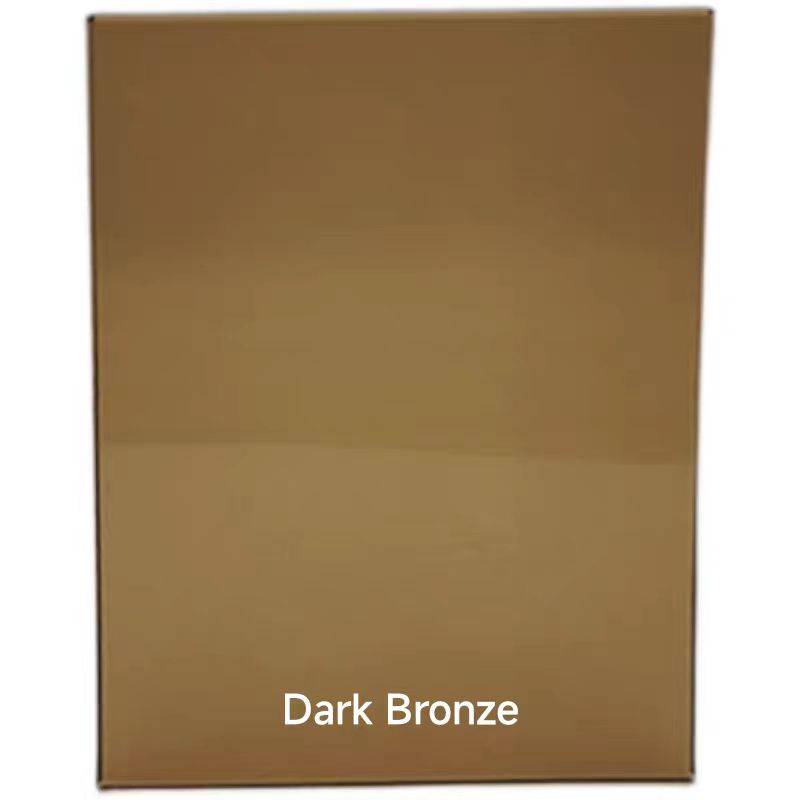

Another crucial consideration is the application of the glass. Tempered glass intended for structural applications or safety-rated environments, such as glass railings or commercial buildings, can incidentally drive the cost up due to additional certifications and compliance with safety regulations. Specialized treatments, such as low-emissivity (Low-E) coatings or tinted finishes, can also add to the cost, as they enhance performance attributes like energy efficiency and glare reduction.

When purchasing 12mm tempered glass, buyers should always seek to understand the price breakdown—what constitutes the cost aside from the basic material fee? Installation costs, potential wastage, and additional processing will also contribute to the overall expenditure. DIY projects may seem appealing for cost-saving, but professional installation is advisable to ensure safety and compliance with building codes.

In summary, the price of 12mm tempered glass is not merely a reflection of the raw material but is shaped by the complexities of manufacturing, regional dynamics, market conditions, and application-specific needs. Buyers should conduct thorough research and consider all relevant factors—including supplier reputation, installation requirements, and long-term value—when budgeting for their glass needs. By taking a comprehensive approach to evaluating costs, individuals and businesses can make informed decisions that align with their project goals while ensuring safety and aesthetic appeal. Whether for residential or commercial purposes, understanding the nuances of pricing can lead to better outcomes in glass selection and usage.