Eastern Float Glass A Reflection of Innovation and Industry

The glass industry has long been a cornerstone for architectural, automotive, and interior design projects worldwide. Among various production methods, float glass has emerged as a significant technology since its inception in the mid-20th century. Eastern float glass specifically refers to float glass produced in Eastern countries, known for their advanced manufacturing techniques and commitment to quality. This article explores the significance, production process, applications, and future of eastern float glass, highlighting its role in modern engineering and design.

Understanding Float Glass

Float glass is produced using a unique process that involves floating molten glass on top of molten tin. This method results in a uniform thickness and perfectly smooth surfaces, making float glass ideal for a variety of applications. The term float derives from the process of glass floating on tin, which allows for an even distribution of thickness and high optical clarity. Eastern countries, particularly China and India, have adapted this technology to meet both domestic and international demands.

The Production Process

The production of eastern float glass involves several critical stages

1. Raw Material Preparation The primary raw materials used in float glass production are silica sand, soda ash, and limestone. These components are carefully measured and mixed to achieve the desired glass composition.

2. Melting The raw materials are heated in a furnace at temperatures exceeding 1,600 degrees Celsius. This process transforms the components into molten glass, which must maintain a specific viscosity for further processing.

3. Floating The molten glass is then poured onto a pool of molten tin. The glass spreads out uniformly over the tin surface, creating a smooth and even thickness. This floating process is a defining characteristic of float glass, providing it with exceptional flatness and clarity.

4. Annealing After the glass has cooled down sufficiently, it passes through an annealing lehr, where it is gradually cooled to relieve internal stresses. This step is crucial for ensuring the durability of the glass.

5. Cutting and Packing Once cooled, the glass is cut into sheets of various sizes and packed for shipping. Quality control measures are implemented throughout the process to ensure each sheet meets industry standards.

Applications of Eastern Float Glass

The versatility of eastern float glass allows it to be utilized in a myriad of applications, including

- Architectural Glass Float glass is extensively used in building facades, windows, and glass doors due to its aesthetic appeal and thermal insulation properties. The ability to manufacture large sheets of glass without distortion has revolutionized modern architecture.

- Automotive Industry In the automotive sector, float glass plays a crucial role in manufacturing windshields, side windows, and rear glass. The clarity and safety of float glass make it a preferred choice for vehicle manufacturers.

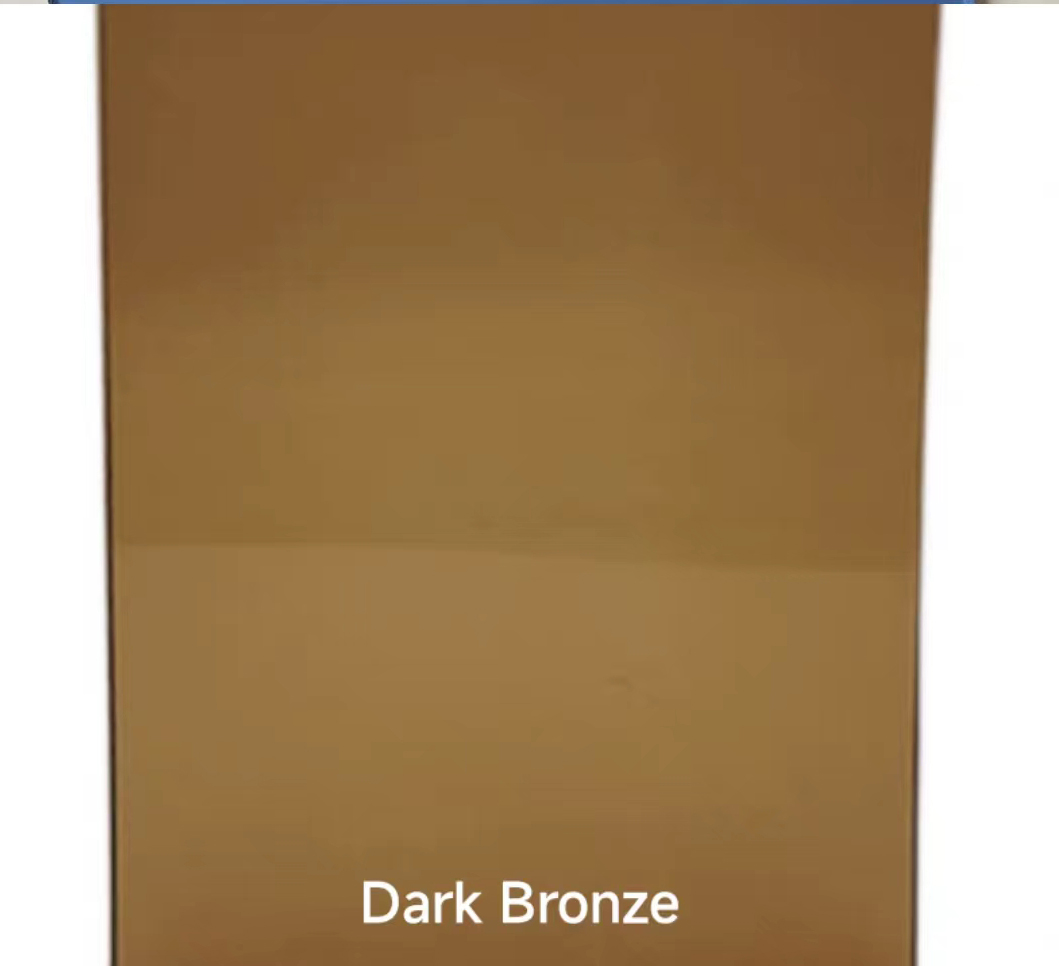

- Interior Design From decorative glass partitions to mirrors and furniture surfaces, eastern float glass contributes to interior design. Its ability to be printed or coated with various finishes allows for endless design possibilities.

Future Trends in Eastern Float Glass

As the demand for float glass continues to rise, eastern manufacturers are focusing on innovation and sustainability to stay competitive. Advanced technologies such as smart glass, which can change transparency based on environmental conditions, are gaining traction. Additionally, there is a growing emphasis on recycling and the use of eco-friendly raw materials in production processes.

Eastern float glass manufacturers are also exploring international markets, establishing partnerships, and enhancing their export capacities. This global outreach not only promotes economic growth but also fosters technological exchange and collaboration.

Conclusion

Eastern float glass exemplifies the blend of tradition and innovation within the glass industry. Its production process, marked by precision and quality control, ensures that the end product meets the demands of various sectors, from construction to automotive design. As we look to the future, the continued evolution of float glass technology in Eastern markets promises exciting developments that will shape architectural and design landscapes while maintaining a commitment to sustainability and resilience. The reflective quality of float glass is not just in its appearance; it also mirrors the growth and transformation of an industry adapting to a rapidly changing world.