Float glass has gained widespread popularity in recent years due to its advanced production methods and remarkable versatility. From the float glass production line to the unique charm of glass fishing floats, this material serves a variety of purposes. Whether it’s in the form of float glass sheets, custom cuts like 4mm float glass cut to size, or even educational float glass videos, it’s clear that float glass is integral to modern industries. This article explores its significance, offering insights into its production, uses, and applications.

The float glass production line is a game-changer in the world of glass manufacturing. This cutting-edge process, which began in the mid-20th century, is responsible for producing large, uniform sheets of glass that are essential in a variety of applications. The process involves melting raw materials and allowing the molten glass to float on a bed of molten tin, resulting in perfectly flat and clear glass. The float glass production line has become the standard method for producing glass used in everything from windows and mirrors to solar panels and automotive glass. Its efficiency and precision make it possible to create large volumes of high-quality glass quickly, meeting the demands of both industrial and commercial sectors. The automation and precision of the float glass production line ensure that the glass produced is uniform, strong, and aesthetically pleasing.

Glass fishing floats are one of the oldest yet still widely used applications of float glass. These floats are primarily used in the fishing industry to keep nets and lines buoyant on the water's surface. Made from float glass, these glass fishing floats are durable and able to withstand harsh environmental conditions, including saltwater, sun, and wind. Their distinct round shape and vibrant colors make them a valuable tool for fishing operations, but they also hold a nostalgic charm. In recent years, glass fishing floats have found a second life as decorative pieces, adding a nautical touch to homes and gardens. The durability and strength of float glass make these floats ideal for enduring the rigors of the fishing industry, while their aesthetic appeal has turned them into collectibles. Whether used for practical purposes or as unique decor, glass fishing floats continue to showcase the versatility of float glass.

The float glass sheet is the cornerstone of many modern construction projects, from residential windows to office building facades. Float glass sheets are produced in a variety of sizes and thicknesses, allowing for customization depending on the needs of the project. Due to the float glass production line’s precision, these sheets have a smooth, uniform surface that is ideal for applications requiring clarity and strength. The float glass sheet offers numerous benefits, including high light transmission, thermal insulation, and soundproofing qualities. Its durability and ease of customization make it the go-to choice for both residential and commercial builders. Additionally, float glass sheets can be treated with coatings that improve their energy efficiency, such as low-emissivity (Low-E) coatings, which reflect heat and reduce energy consumption. Whether used in windows, doors, or partitions, float glass sheets are indispensable to modern architecture and construction.

The ability to order 4mm float glass cut to size opens up a world of possibilities for both small-scale DIY projects and large construction projects. 4mm float glass cut to size is commonly used for applications that require a thinner, lighter sheet of glass, such as picture frames, glass tabletops, and small windows. This level of customization ensures that the glass fits perfectly into the designated space, reducing waste and ensuring a precise fit. The ease with which 4mm float glass can be cut to size makes it ideal for bespoke installations and specialized applications. With the help of advanced cutting techniques, 4mm float glass cut to size can be tailored to fit virtually any design, whether it’s for a unique decorative piece or a custom door or window. This flexibility is a key advantage of float glass, providing homeowners and designers with the ability to achieve a polished, professional look while keeping costs down.

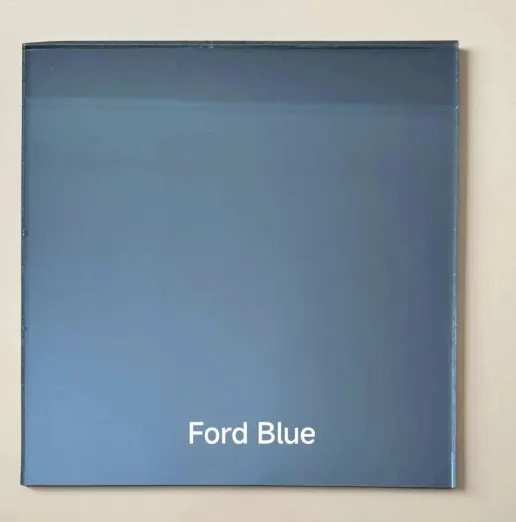

For those interested in learning more about how float glass is made, watching a float glass video can offer a fascinating insight into the process. These videos often showcase the entire journey of float glass production, from raw materials to the finished product. A float glass video typically begins with the melting of raw materials, followed by the formation of molten glass that floats on a bed of molten tin, giving it its flat and smooth surface. The float glass video offers a step-by-step explanation of how different types of glass are produced, including clear, tinted, and coated varieties. By watching these videos, viewers can gain a deeper understanding of the complex process that goes into creating the glass products they use every day. These videos not only provide valuable knowledge about the float glass production line, but they also highlight the level of innovation and precision required to manufacture glass that meets the highest standards of quality.

In conclusion, float glass is an essential material in modern manufacturing, construction, and design. The float glass production line ensures high-quality, uniform glass, while glass fishing floats and float glass sheets showcase the material's practical applications. The availability of 4mm float glass cut to size makes it easier for consumers and businesses to create custom solutions. Meanwhile, a float glass video offers an inside look into the intricate process behind the product. Whether you’re a builder, a designer, or just someone looking for the best materials, float glass offers unmatched versatility, quality, and value.