The Float Glass Center A Hub of Innovation and Excellence

In the realm of modern construction and design, glass has emerged as a quintessential material. Its versatility and aesthetic appeal have made it a staple in architecture, interior design, and automotive industries. At the heart of this glass revolution is the Float Glass Center, an innovative facility dedicated to the production and research of float glass technology. This article delves into the significance, processes, and future prospects of the Float Glass Center.

The Significance of Float Glass

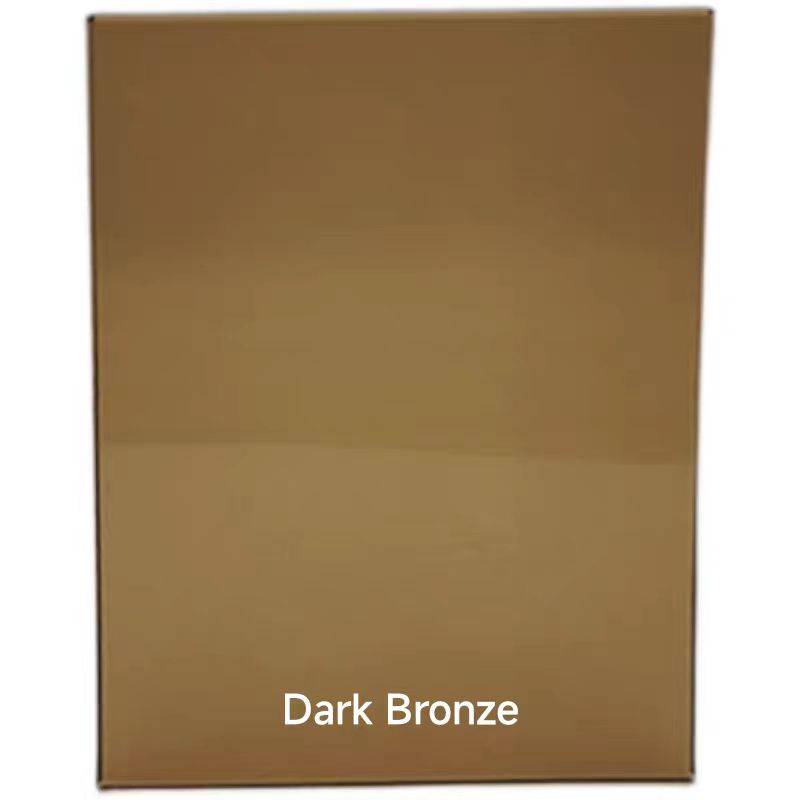

Float glass, a type of flat glass, is produced through a unique process that was developed in the 1950s. The process involves floating molten glass on top of molten tin, resulting in a smooth, flat surface. This technology has revolutionized the glass industry by providing a product that is not only clear and flawless but also offers excellent thermal and optical properties. Float glass has myriad applications, ranging from windows and facades in buildings to screens and mirrors.

The Float Glass Center serves as a research and development hub for advancing this technology. It plays a crucial role in improving the quality of float glass while innovating new types of glass products that cater to the ever-evolving demands of the market. This facility is not just a manufacturing site; it is a place where scientists and engineers collaborate to push the boundaries of what is possible with glass.

The Float Glass Manufacturing Process

The journey of float glass begins with raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully weighed and mixed, then heated in a furnace at high temperatures until they melt into a molten glass. The unique float glass process involves pouring this molten glass onto a bed of molten tin, which allows the glass to spread out evenly, creating a perfectly flat surface.

As the glass solidifies, it undergoes rigorous quality checks to ensure it meets industry standards. The production process requires meticulous attention to detail, as even the slightest impurities can affect the final product's clarity and strength. Once the glass has cooled and is cut to size, it is treated to enhance its durability and energy efficiency, with options for coatings that improve insulation and UV resistance.

Research and Innovation

One of the key roles of the Float Glass Center is to foster innovation in glass technology. Researchers at the center are constantly exploring new methods and materials to enhance the properties of float glass. This includes developing energy-efficient variants, such as low-emissivity glass, which minimizes heat transfer and is increasingly favored in energy-conscious construction projects.

Moreover, the center actively collaborates with academic institutions and industry partners to explore the potential of smart glass technologies. Smart glass can change its transparency based on environmental conditions or user preferences, making it a game-changer for buildings that require adaptive lighting and privacy solutions.

Environmental Considerations

Modern manufacturing processes emphasize sustainability, and the Float Glass Center is no exception. The center is committed to minimizing its environmental impact by adopting eco-friendly practices, such as recycling glass cullet (scrap glass) in production and using renewable energy sources in manufacturing processes. Furthermore, the development of energy-efficient glass products contributes significantly to reducing the carbon footprint of buildings, aligning with global sustainability goals.

The Future of Float Glass

As we look to the future, the Float Glass Center is poised to lead advancements in glass technology. With architecture trends leaning towards more transparent materials and energy efficiency, the demand for high-quality float glass is expected to rise. The center's commitment to research and innovation will ensure that it remains at the forefront of this evolving industry, providing solutions that meet the technological, aesthetic, and environmental needs of the 21st century.

In conclusion, the Float Glass Center is more than just a manufacturing facility; it is a beacon of innovation in the glass industry. By continuously improving the float glass production process and exploring new technologies, it is paving the way for a brighter, more sustainable future in glass applications. As designers and architects embrace the potential of glass, the Float Glass Center will undoubtedly play a vital role in shaping the skylines of tomorrow.